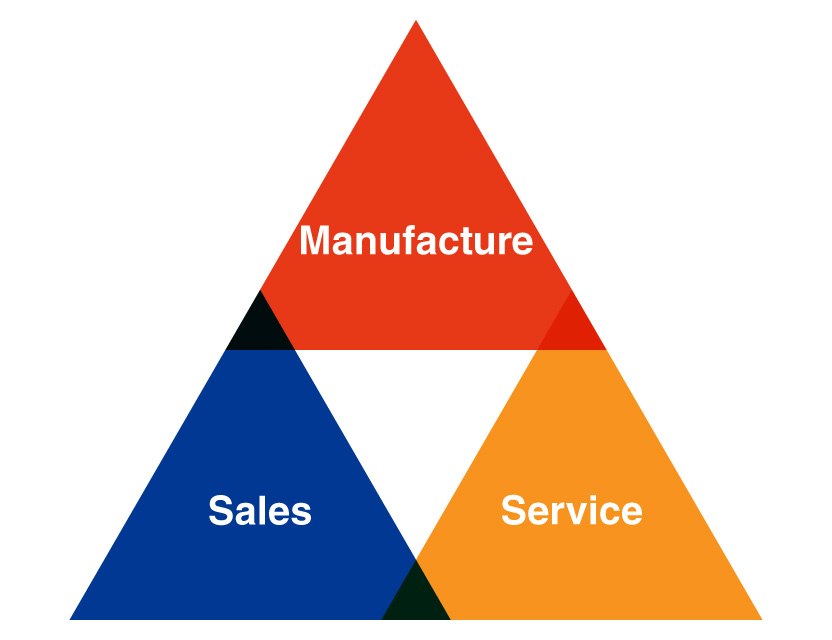

Business Domain

Strengths of

Synergy effects from our unique business model that integrates manufacturing, sales, and service.

We are not just a special tool manufacturer, but a “manufacturing problem-solving company”.

-

Manufacturing

The only special tool manufacturer in Japan that provides total design and manufacturing of tools, jigs, and equipment around machining points.

C-max supports the entire process around machining, which is essential to production, with its accumulated expertise.

Our special tools are innovative and always R&D oriented, achieving to be indispensable to today's automotive industry.

-

Sales

We deliver cutting-edge and unique products from all over the world.

C-max also flexibly utilizes other companies' products to solve customers' problems.

Being up-to-date with the world of manufacturing, sharing information with our global network, enabling us to provide quick & flexible solutions.

-

Service

The total engineering services in everything around machining points.

Over 1000 members are providing services worldwide.

We offer prototype parts, design of production lines and tool management after the production has started with a one-stop solution.

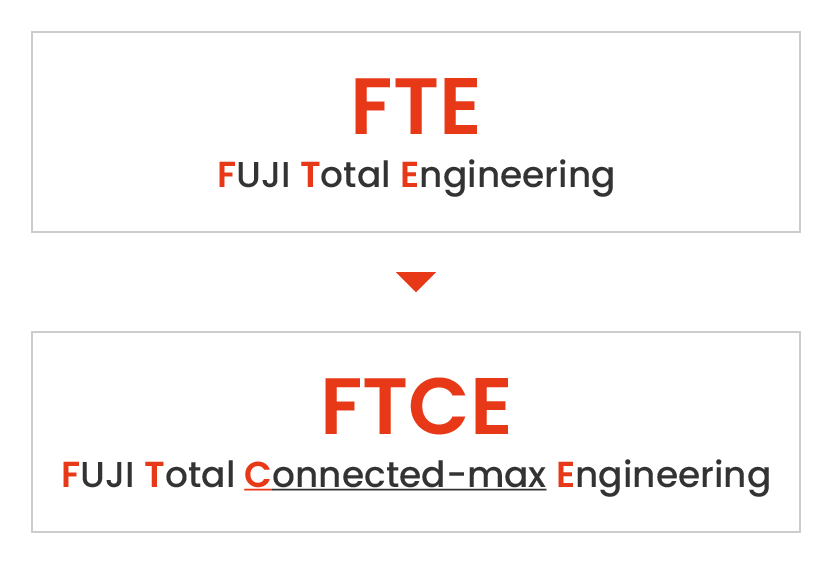

From FTE business to FTCE business

We create and maximize value for our customers by connecting with

FUJISEIKO's solutions to their diverse needs, technology, data, and manufacturing.

-

Tooling

- SPECIALTOOLING

- Cutting Tools

- Electric Vehicle Tools

-

Equipment

- Facilities/Equipment

- Upgrading operation

- Transferring Equipment

- Functional Jigs

- Automation

- Robot/FA

- System Integrating

- Special Robot Modules

-

Trading

- Tools & Equipment

- Engineering services

-

Management

- Logistics

- Tool Control

- Inventory Control

-

Prototype Parts Manufacturing

- Prototype coordination

- Small volume production

- On-site demonstration

-

Overseas

- Collaboration to meet each country's local conditions and market environment

C-max on the Flow until Full Production

Our unique know-how, gained from automotive industry, now to the various other industries.

-

Prototype

-

Planning

-

Validation

-

Preparation

-

Equipment

procurement -

Initial/

Start Up -

Mass

Production

Glossary

- ABS

- ABS (After & Before Service) offers from “post-delivery setup”, “inventory management” and “5R service for tools” for the purpose of “better products for longer use”

- Parts Machining, Injection Molding

- We offer machining of prototypes & production of assy parts, using our unique engineering know-how.

As for plastic molding, our integrated service of mold manufacturing is avalilable from prototype to mass production - Jigs

- As the only tool manufacturer in Japan that designs and manufactures jigs, we offer work clamping jigs that are highly compatible with our tools.

- 5R Service

- 5Rs (Repair, Recycle, Regrind, Reuse, and Reduce) as one of our main business in environmental measures, will improve customer's productivity in terms of cost and delivery.