FUJISEIKO's Manufacturing

FUJISEIKO's Approach to Automation

We aim to provide our customers with high-quality, highly functional products, and we work every day to improve our manufacturing capabilities with the keyword “automation,” which is a challenge in “high-mix, low-volume production.”

Realizing Automation of Manual Work in Cutting Tool Manufacturing

-

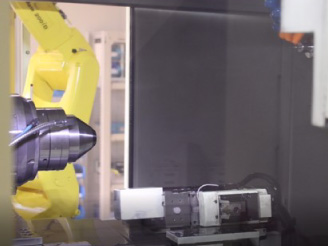

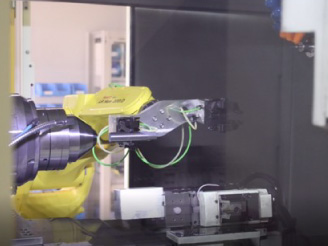

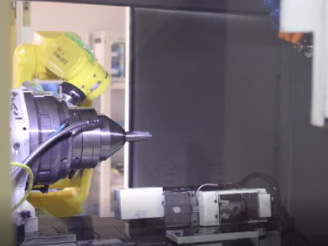

Attached work carry

Utilization of industrial robots

-

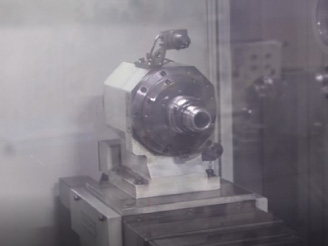

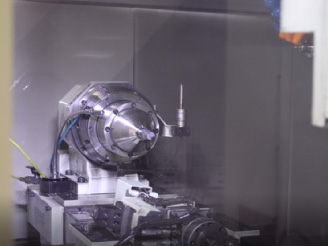

Grinding PCD

Manual work

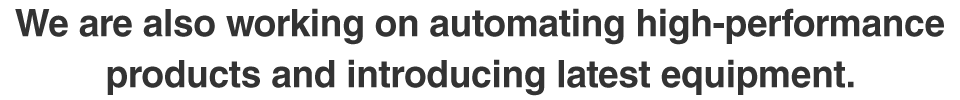

PCD automatic cylindrical machine

Automation

-

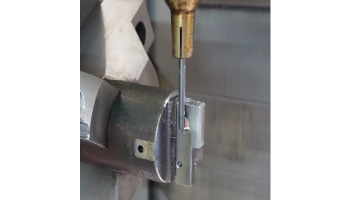

Tool replacement

Utilization of universal chucks

-

Aluminum bracket

-

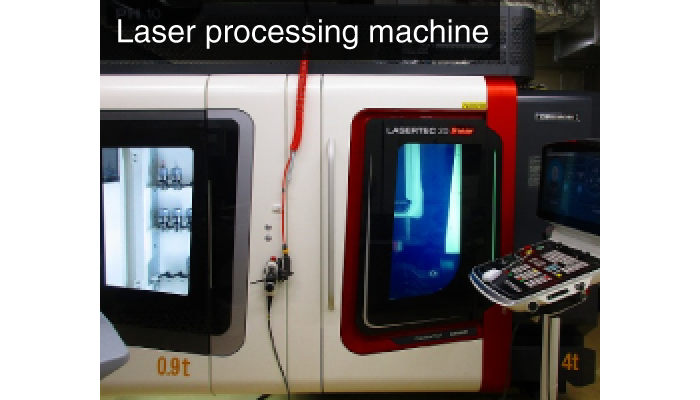

PCD laser breaker

-

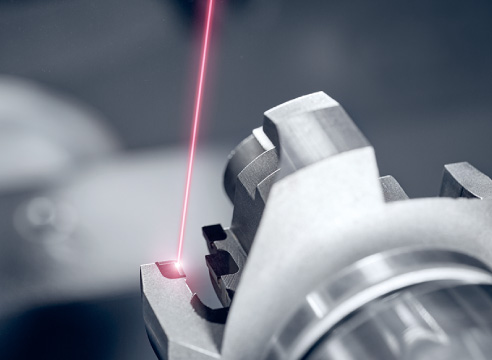

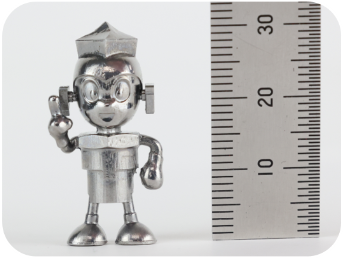

Microfabrication product

Cutting Tool Area

Autonomation

Until now, round tools have been made by hand by craftsmen. FUJISEIKO's production engineering team aimed for an “automated production line” for a wide variety of small-volume production of round tools. The following is a case study of a solution to a problem that was solved through the realization of an idea.

-

Phase 1

Automated machines are introduced to carbide tool production lines.

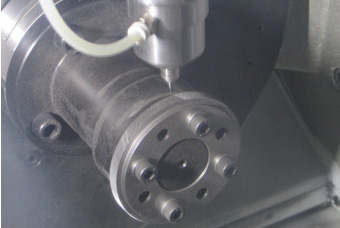

Complete carbide tool fabrication process in a single machine

-

Phase 2

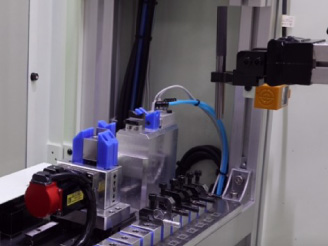

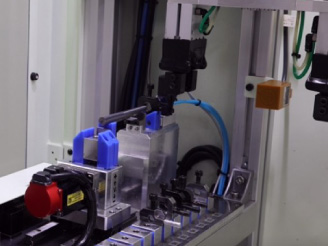

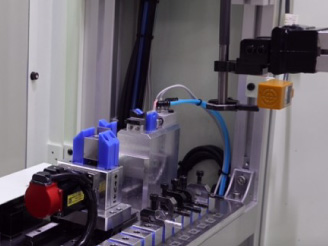

PCD tool body built with unmanned continuous machining

Automation of machining & transfer and process integration

-

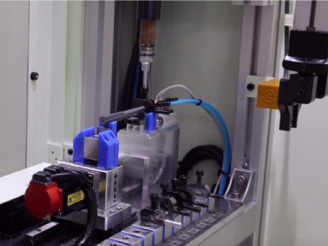

Phase 3

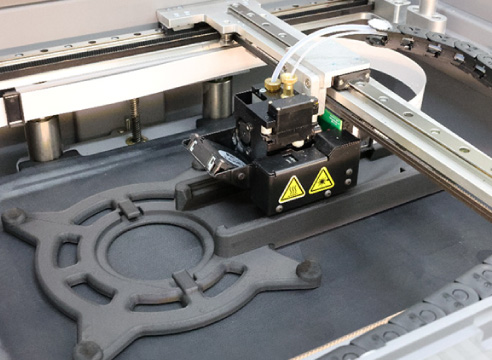

PCD tool finishing process

Established by craftsmanship & new machining methodAutomated machining of high-precision, high-difficulty cutting edges

High Functional Product Area

Manufacturing

Expanding automation into new fields and into highly functional products such as holders and jigs. We continue to evolve “Monozukuri” (manufacturing) by introducing the latest equipment and developing in-house jigs, challenging further possibilities and materializing our ideas.

-

Phase 1

Introduced 5-axis machining center

5-axis micro-machining centerAutomatic pallet change improves utilization rate

-

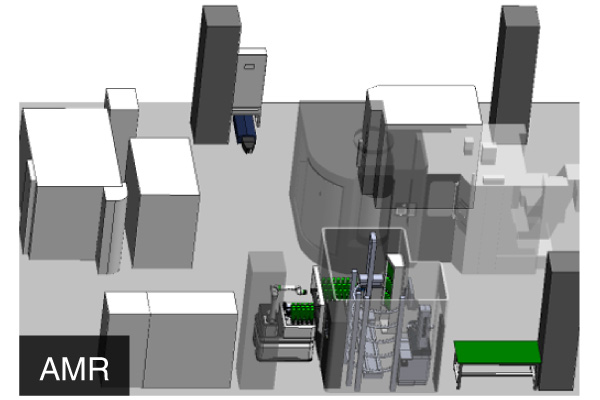

Phase 2

AMR-linked tool stocker to be introduced

Continuous unmanned operation is possible even during nighttime and holidays with off-site presetting and self-supply of spare tools.

-

Phase 3

Promoting Automation