FUJISEIKO's Manufacturing

3S LINE

The Automation Concept of FUJISEIKO

A line that consolidates processes for high-mix, low-volume production,

reduces manpower, materials, and setup time, and achieves even smaller scale

Conventional line

Each process have machines and need to move the next process

- Material

- Cylinder

- Flute

- Blade

attachment - Completed

3S LINE

All equipment is integrated

into one unit, eliminating

the need for movement

between processes.

- Material

-

3S LINE

Aggregation

Omission

Small scale

- Completed

Key Points to Automation Line

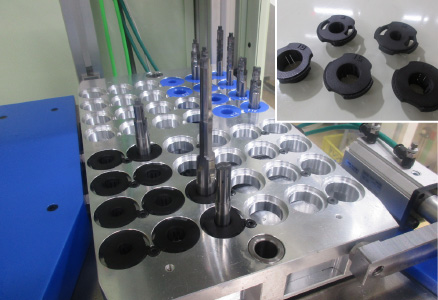

Case 1Universal chuck

In-house

design

Development

product

Since there are many different types of tool diameters to be manufactured,

there is a limit to the number of tools that can be processed in one setup

when using a collet exchange system.

“Amazing Ideas / Facts!”

It is possible to clamp workpieces from ø5 to ø20!

It can be used for a long time by maintaining the clamp jaws!

![]()

Clamping possible from ø5 to ø20!!

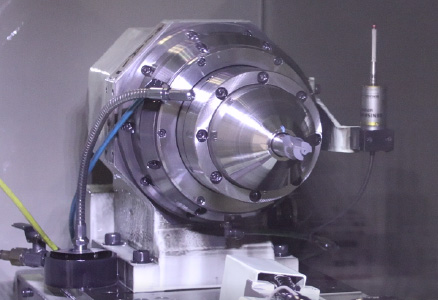

Case 2Automatic work carry attachment/detachment device

FUJISEIKO's

system

It is necessary to attach a work carry for cylindrical process at both centers.

It is hard for us to reattach it every time when the processing area is changed.

“Amazing Ideas / Facts!”

We make a detachment system that is used industrial robots

and realize the unmanned operations.

![]()

Realizing unmanned operation by industrial robots!!

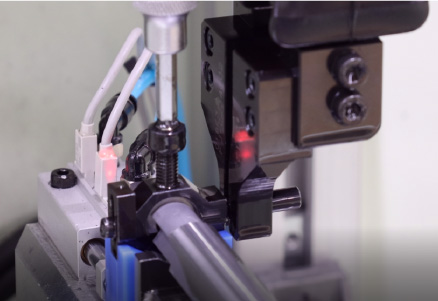

Case 3Work transport sleeve

Works made

with our own

3D printer

Since there are many types of tools to process,

it is a hassle to prepare pallets each time.

“Amazing Ideas / Facts!”

Sleeve can be removed and attached with one hand!

The minimum number of pallets is sufficient since the base holes are standardized!!

![]()

Easy to attach and remove with one hand!

Small scale with minimum number of pallets!!