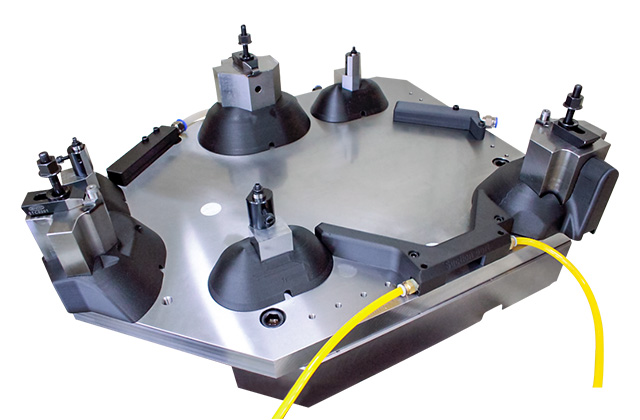

Jig with Chip Accumulation Prevention

Solves the problem of chip

accumulation on machining jigs!

- 3D modeling technology and chip discharge mechanism solve accumulation problems.

- Simply attaching functional parts to existing jigs, reduces work piece defects and machine stops in the production line caused by chip accumulation.

“Amazing Ideas / Facts!”

Simple mounting of functional parts onto an existing jig prevents chip accumulation and then improves production efficiency.

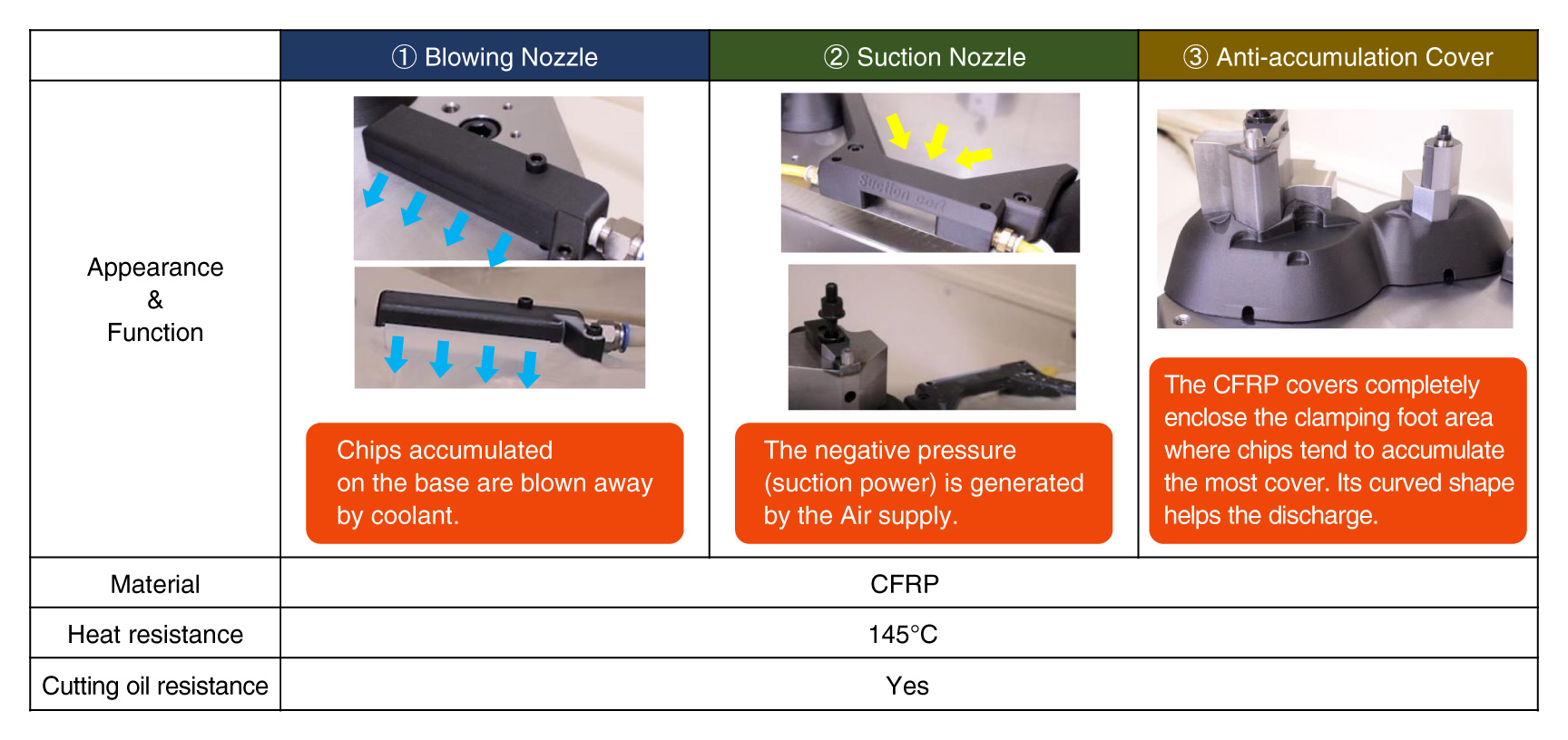

The Functional parts (Nozzles and Covers) are made of 3D printed CFRP, which are durable and heat & cutting oil resistant, designed to make an efficient chip evacuation.

The 3D printing technology allows free shape of nozzles and covers that can be fitted to existing jigs, best eliminating possible chip accumulation.

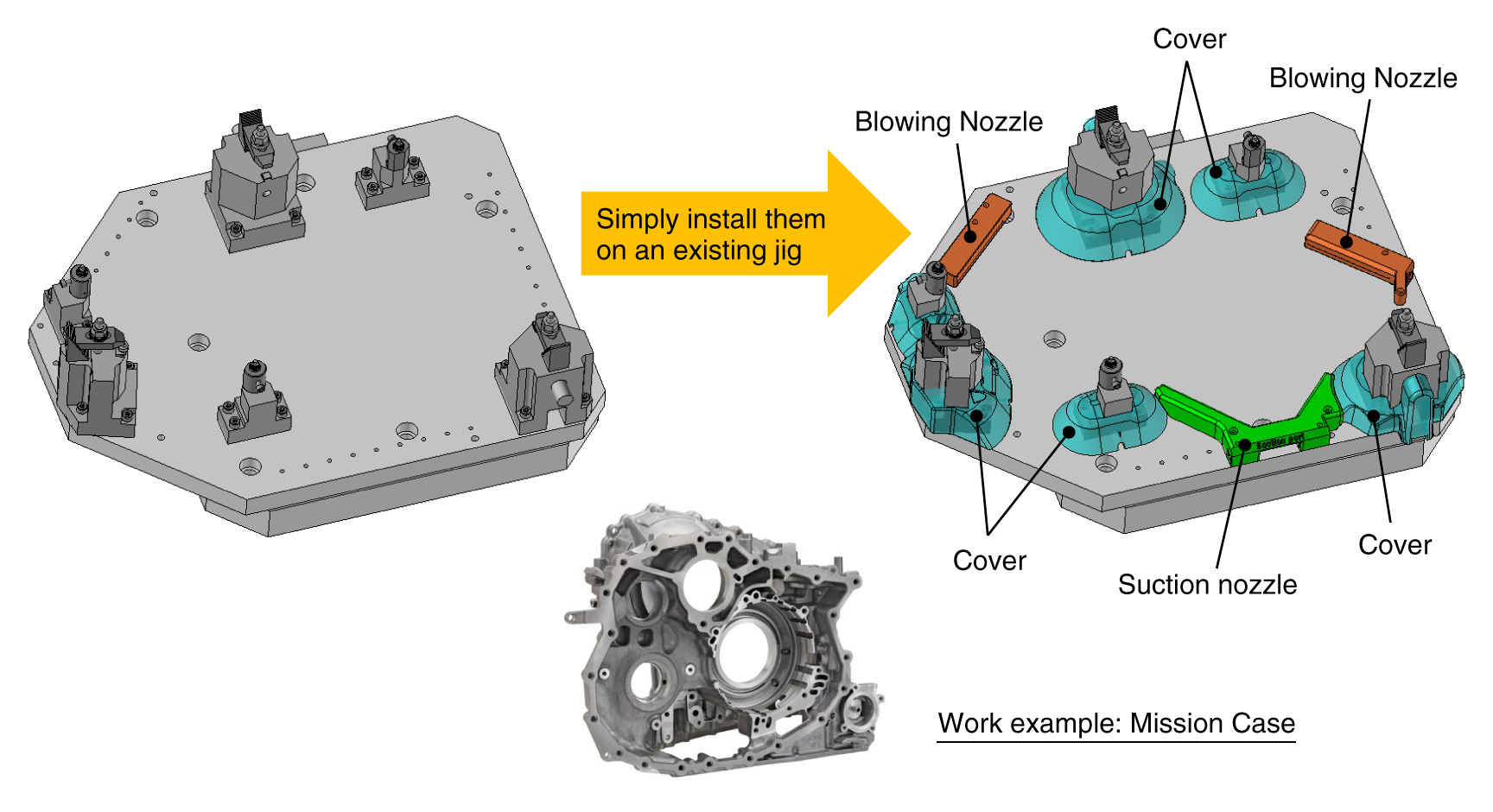

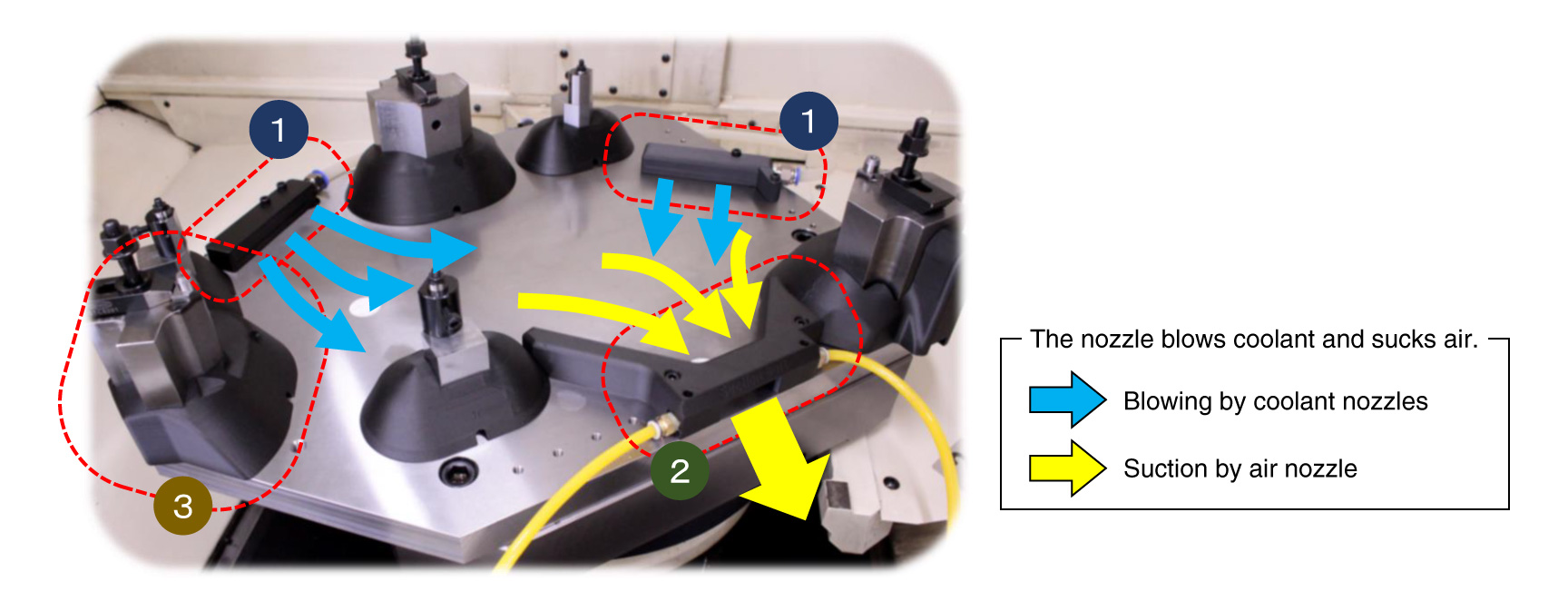

How to use the nozzles and covers

POINT!

Free-form discharge mechanism and space-saving designExcellent !

Background / Point for Development

Background

- Chips tend to accumulate in areas where coolant does not easily reach (corners of jigs).

Efficient chip evacuation is always an issue to prevent machining defects and machine stops during production.

Point for Development

- The “Jig with Chip Accumulation Prevention” can be added onto the existing jigs, eliminates the chip accumulation by using blowing nozzles & suction nozzles attached to the jig and a cover that does not impede discharge.

- The nozzles and covers are made of additive manufactured CFRP, that can be made into complex shapes with a high degree of freedom, and are heat and cutting oil resistant, keeping good/clean condition inside the machine for better productivity.