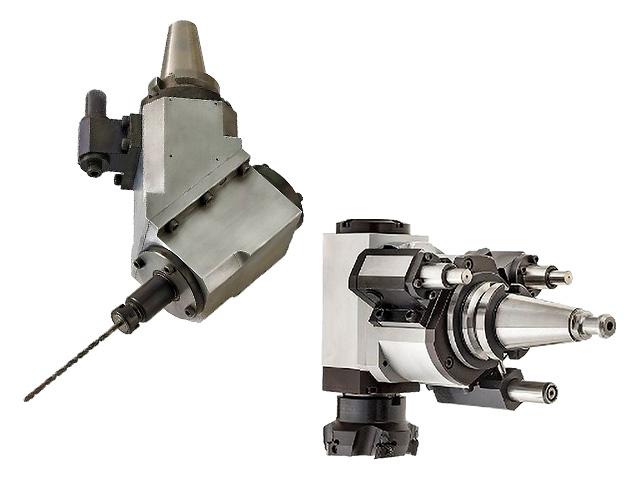

Angular unit

Various product lineup,

to meet user needs

- Applicable in processes such as drilling, grooving, deburring, facing, etc.

- Rigidity can be increased with “Plus Foot” for high load machining

Product lineup

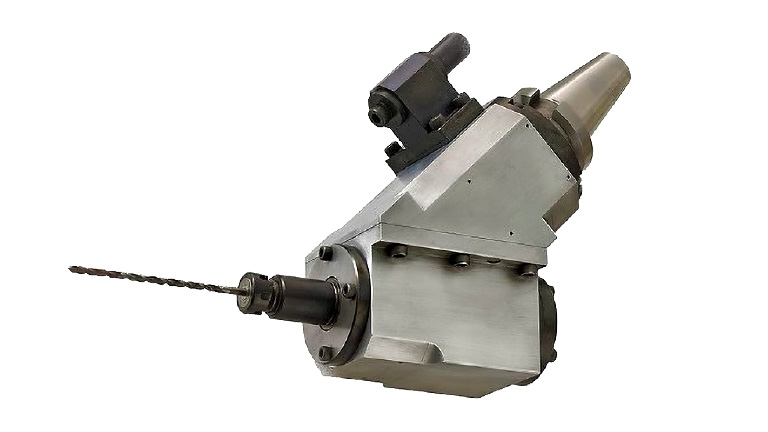

Standard

Drilling, Tapping

- Applicable condition

- N=2000rpm

- f=0.14mm/rev

- Interface: #40, #50

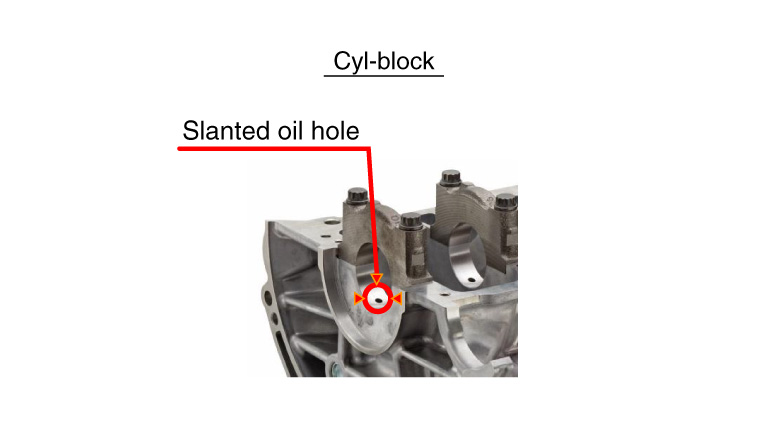

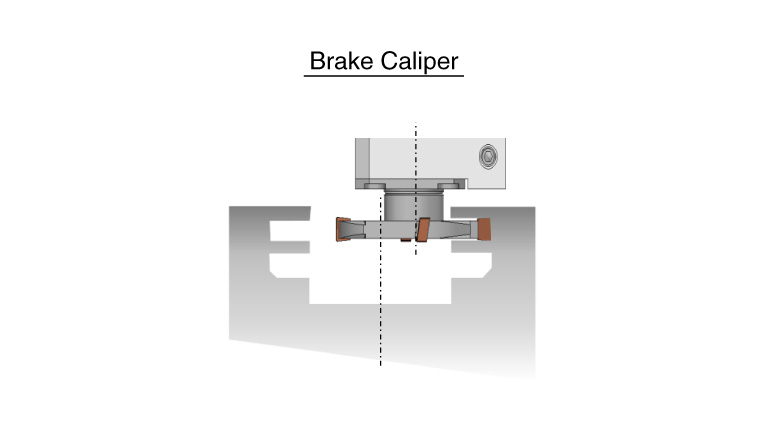

Application ex

Grooving

Grooving

- Applicable condition

- N=1500rpm

- f=0.1mm/rev

- Interface: #50

Application ex

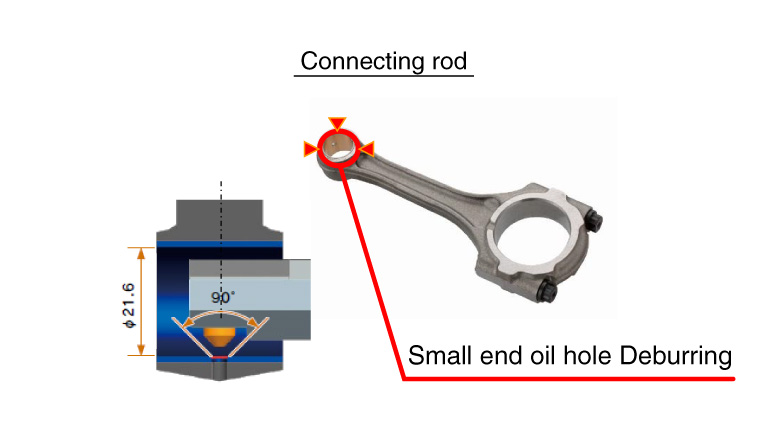

Mini-angular

Small diameter deburring

- Applicable condition

- N=400rpm (Input)

- N=600rpm (Output)

- f=0.05mm/rev

- Interface: #40

Application ex

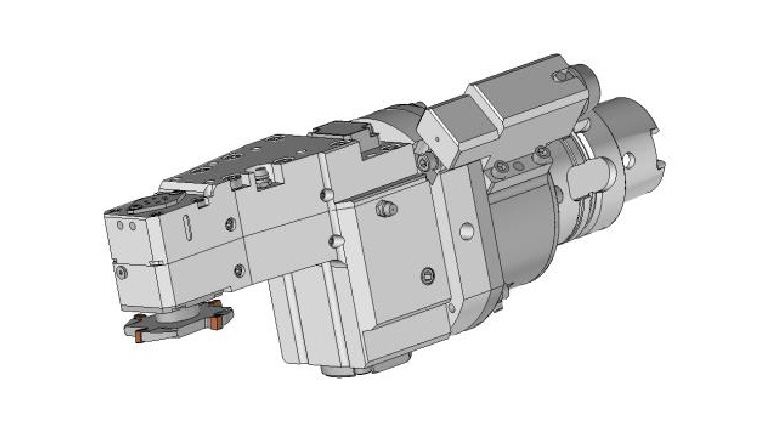

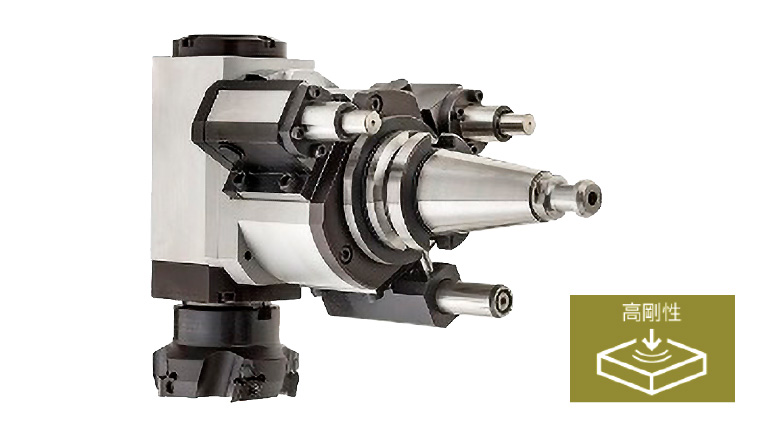

Plus FootPAT.

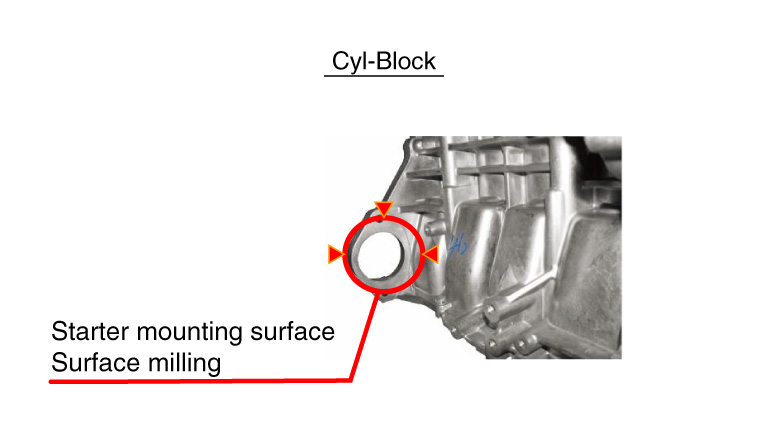

Facing

- Applicable condition

- N=2000rpm

- f=0.1mm/rev

- Interface: #50

Application ex

“Amazing Ideas / Facts!”

Light weight and high rigidity from the optimal internal structure and its body shape, The rigidity is further enhanced with Plus Foot for drilling on sloped surfaces, grooving, small diameter chamfering, and high-load machining.

POINT!

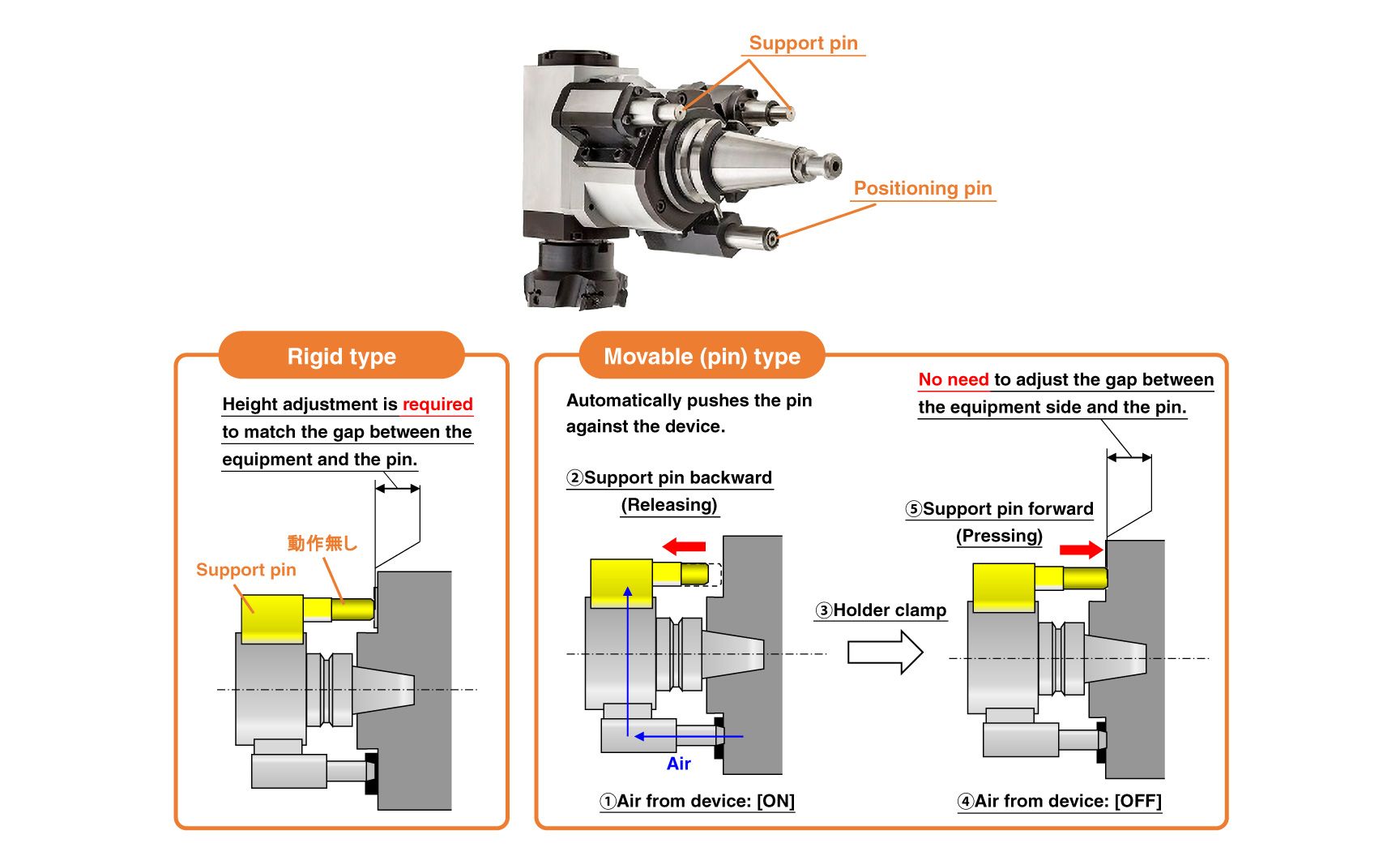

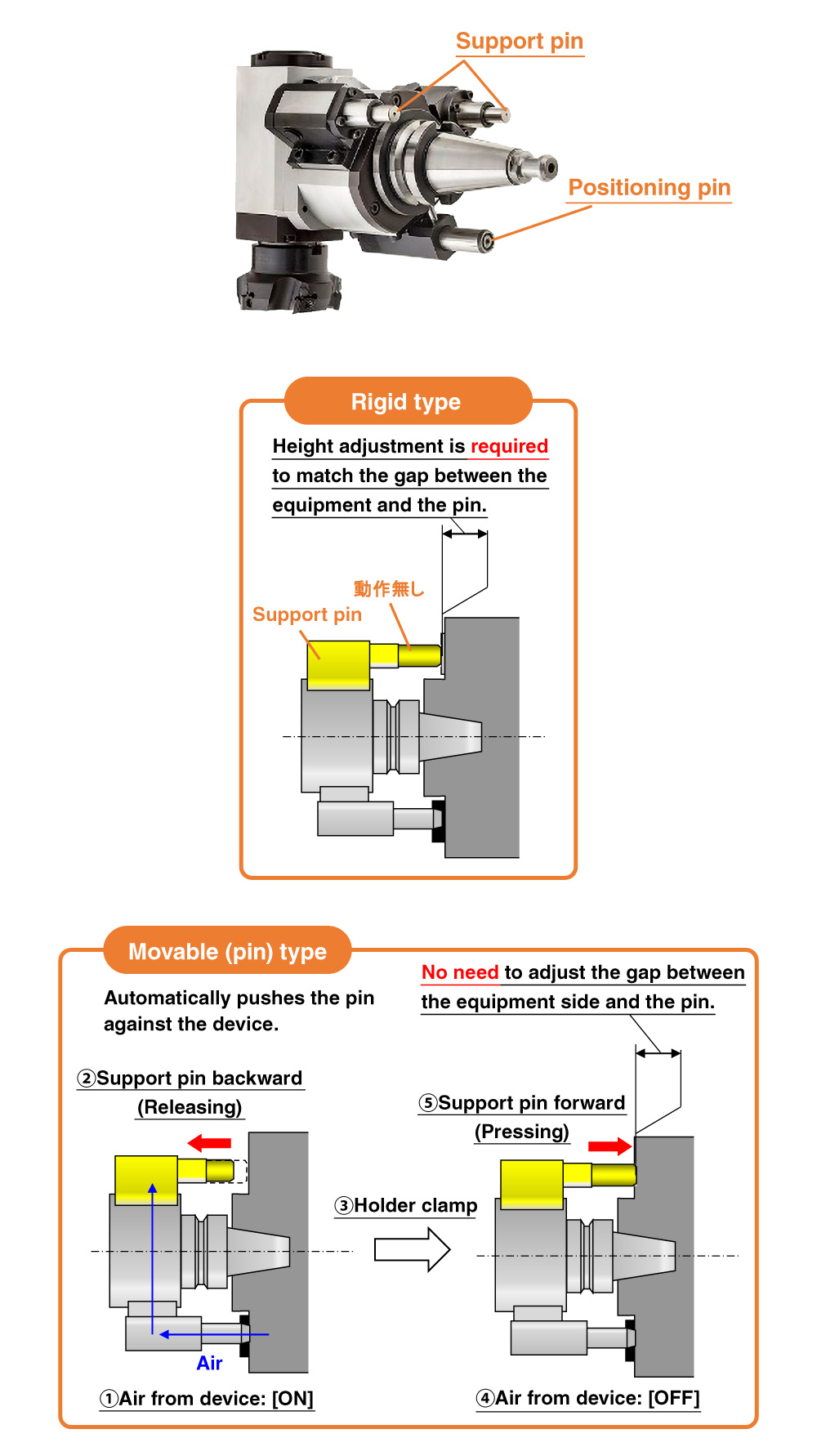

Advantage of plus foot typeExcellent !

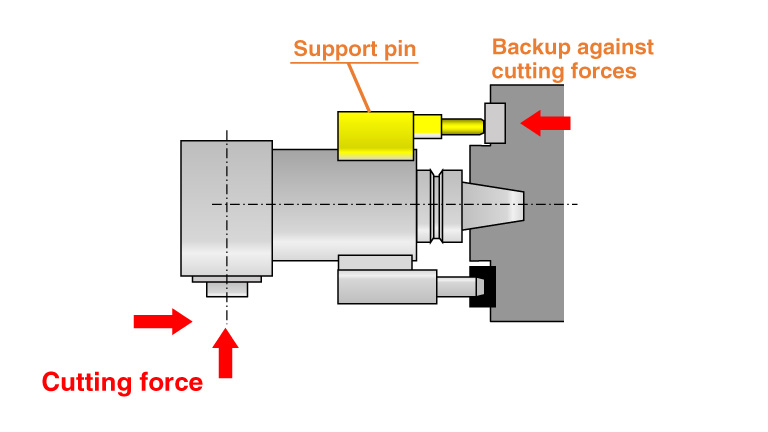

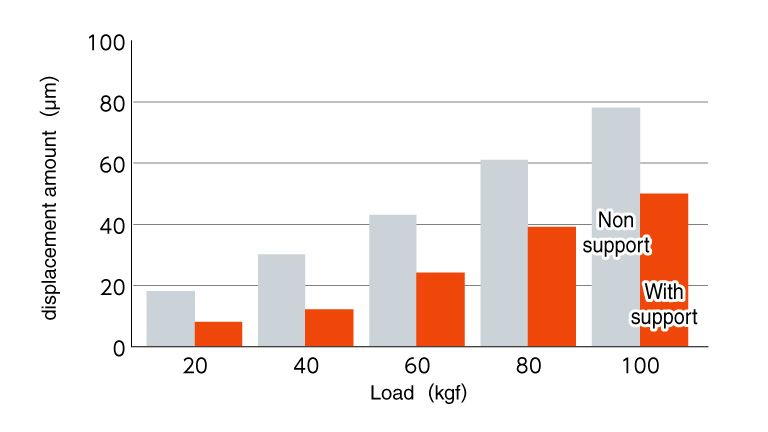

Support pin prevents holder displacement, ideal for high load machining such as milling.

Holder displacement reduced by up to 55%Good !

Point!

Different types of support pins are available for different needsExcellent !

Background / Point for Development

Background

- Conventional units have low rigidity and large holder sizes, so their uses are limited to general hole machining.

- Special jigs or equipments are normally required for processes other than general holes.

Point for Development

- Angular units with light weight and high rigidity from its optimal internal structure and body shape, enabling machining center processing (drilling on inclined surfaces, grooving, small-diameter internal chamfering, and face milling) and resulting in less investment.