ATC Type Honing Head

Automatic Tool Change

Honing processing can be done

with a machining center!

- Reduces capital investment and fits multi-product mixed-flow production.

- Honing heads that can be machined on general-purpose machines.

- Automatic Tool Change (ATC) is available

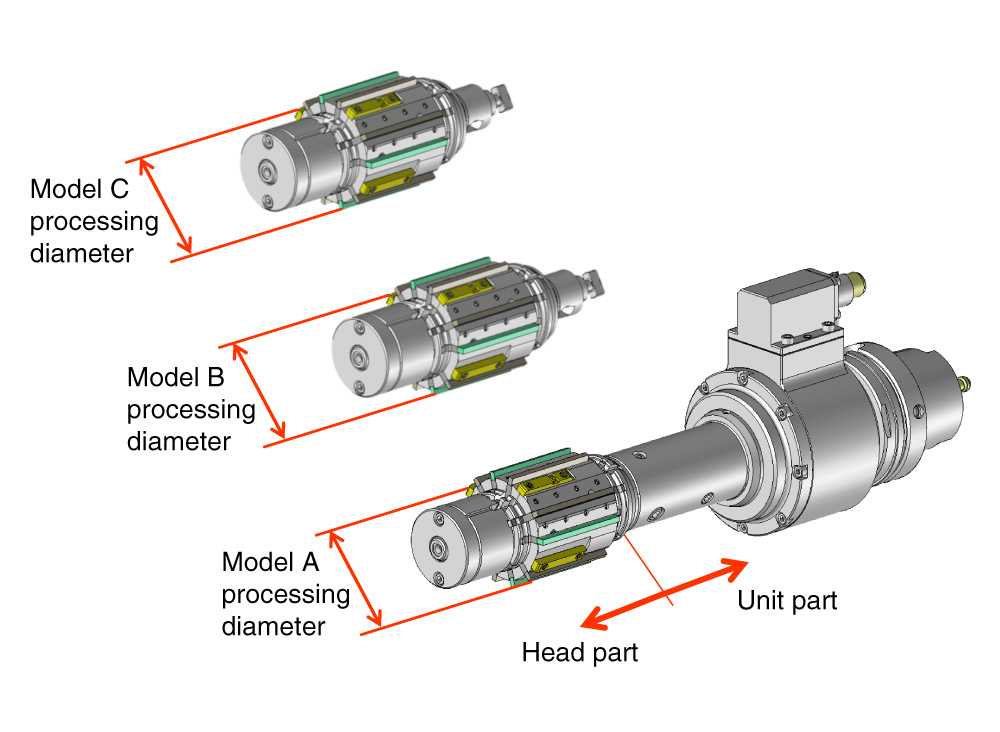

- Split structure for head replacement

“Amazing Ideas / Facts!”

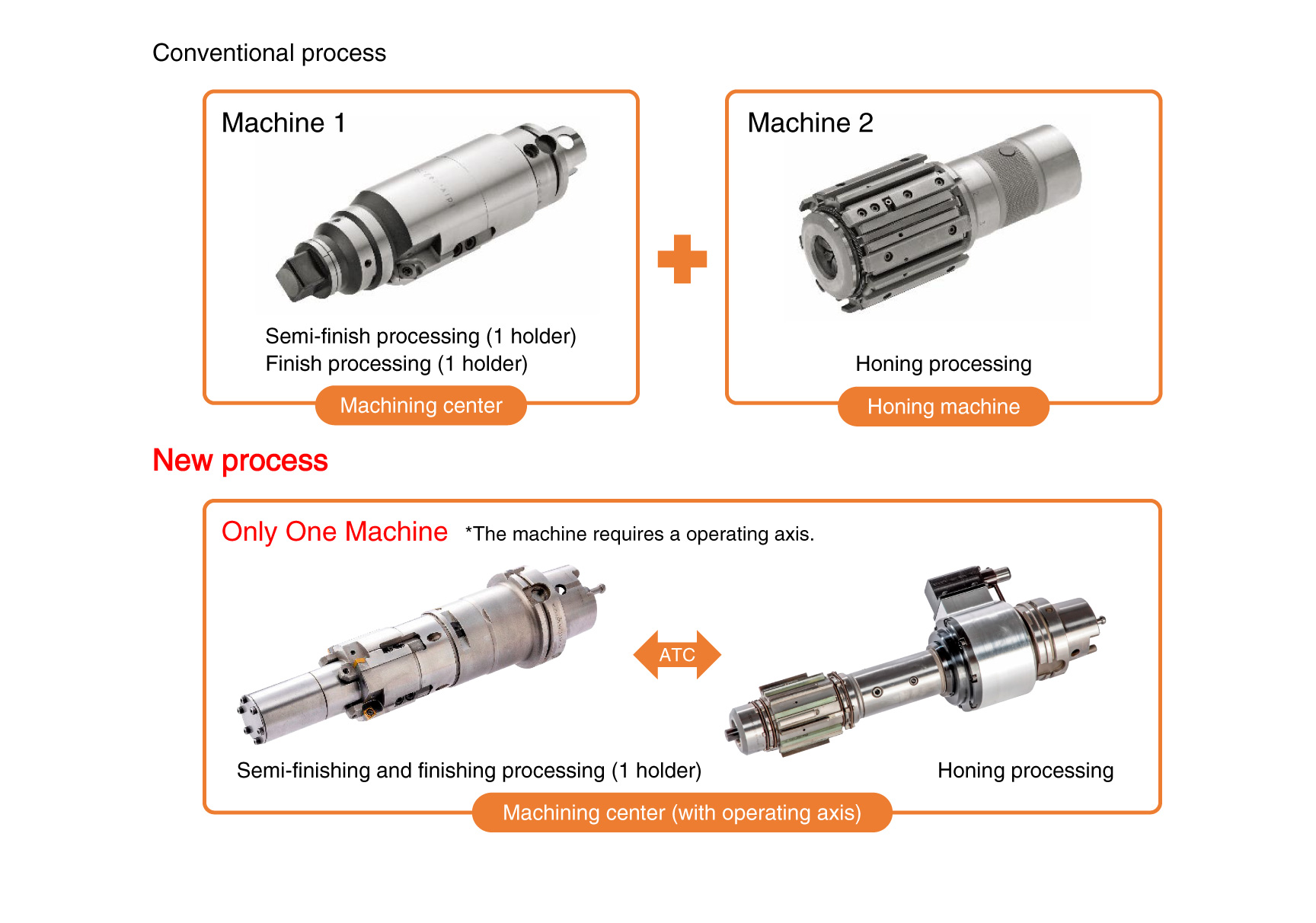

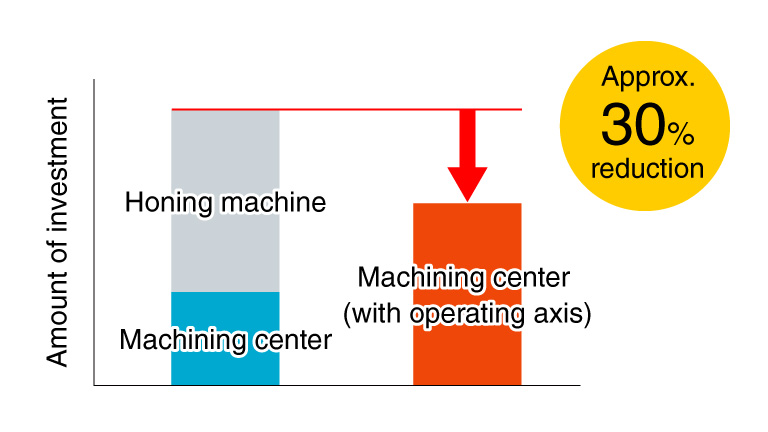

The ATC honing head enables honing processing on machining centers with operating axes, various operations such as honing and drilling can be integrated in one machining device.

As an example, in Bore hole (CY block) ,One and the same M/C can be used for boring and honing, resulting in investment reduction.

ATC has made it easy and quick to fit to workpieces with different (machining) diameters. (i.e. Multi-Product production.)

POINT!

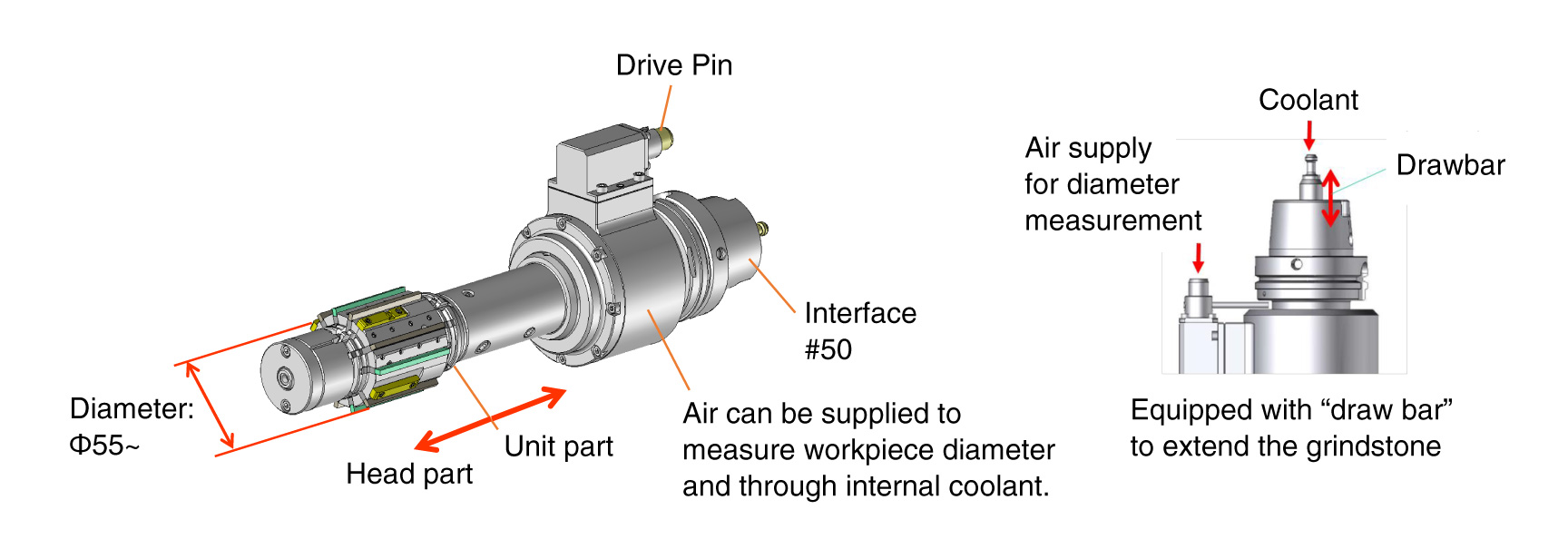

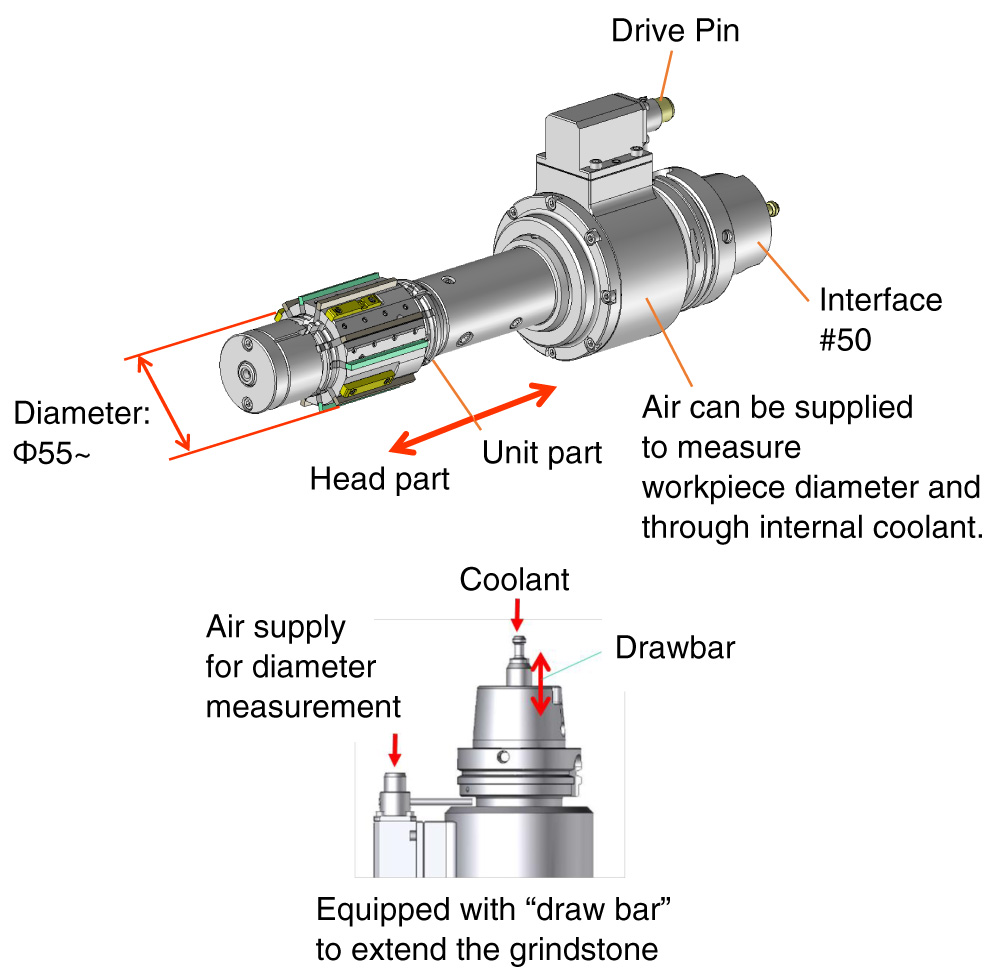

Honing function built into the unitExcellent !

POINT!

A single machining center completes the machining of a bore hole in a blockExcellent !

Less machines = Less InvestmentGood !

Equipment in use

POINT!

Replaceable heads for various workpiece diameters.Excellent !

Background / Point for Development

Background

- CY block bore hole requires strict accuracy in diameter, coaxiality, and roundness. Therefore, it is necessary to measure the diameter of the workpiece and adjust the grinding wheel for machining, and it is common to use a honing machine with an operating axis.

- However, the introduction of a separate honing machine requires an extra space for installation and the significant capital investment.

Point for Development

- The ATC type realises the honing processing on a machining cente, applying the technology cultivated with the honing head for conventional honing devices and an internal mechanism that stabilizes the rotation axis.

- In bore hole machining (CY block), the same equipment is used for boring and honing, no need to install a separate honing machine, reducing the investment cost.