Balance Reamer

Excellent finishing accuracy even in

deep hole drilling with

outstanding balanced shape!

- ‘Excellent guiding ability’ + ‘outstanding rotational balance’, ideal for deep hole finishing!

- Outstanding balanced shape and

optimum guide arrangement

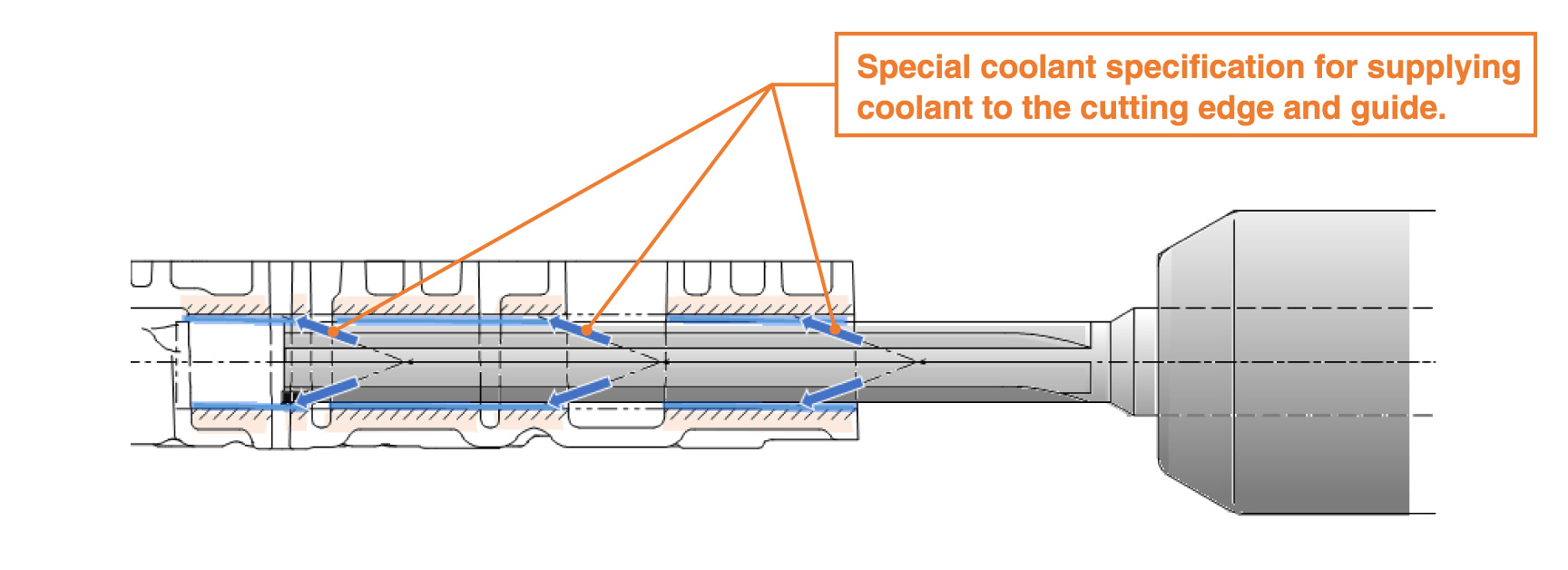

provides high-precision machining. - Special coolant design

prevents workpiece damage.

“Amazing Ideas / Facts!”

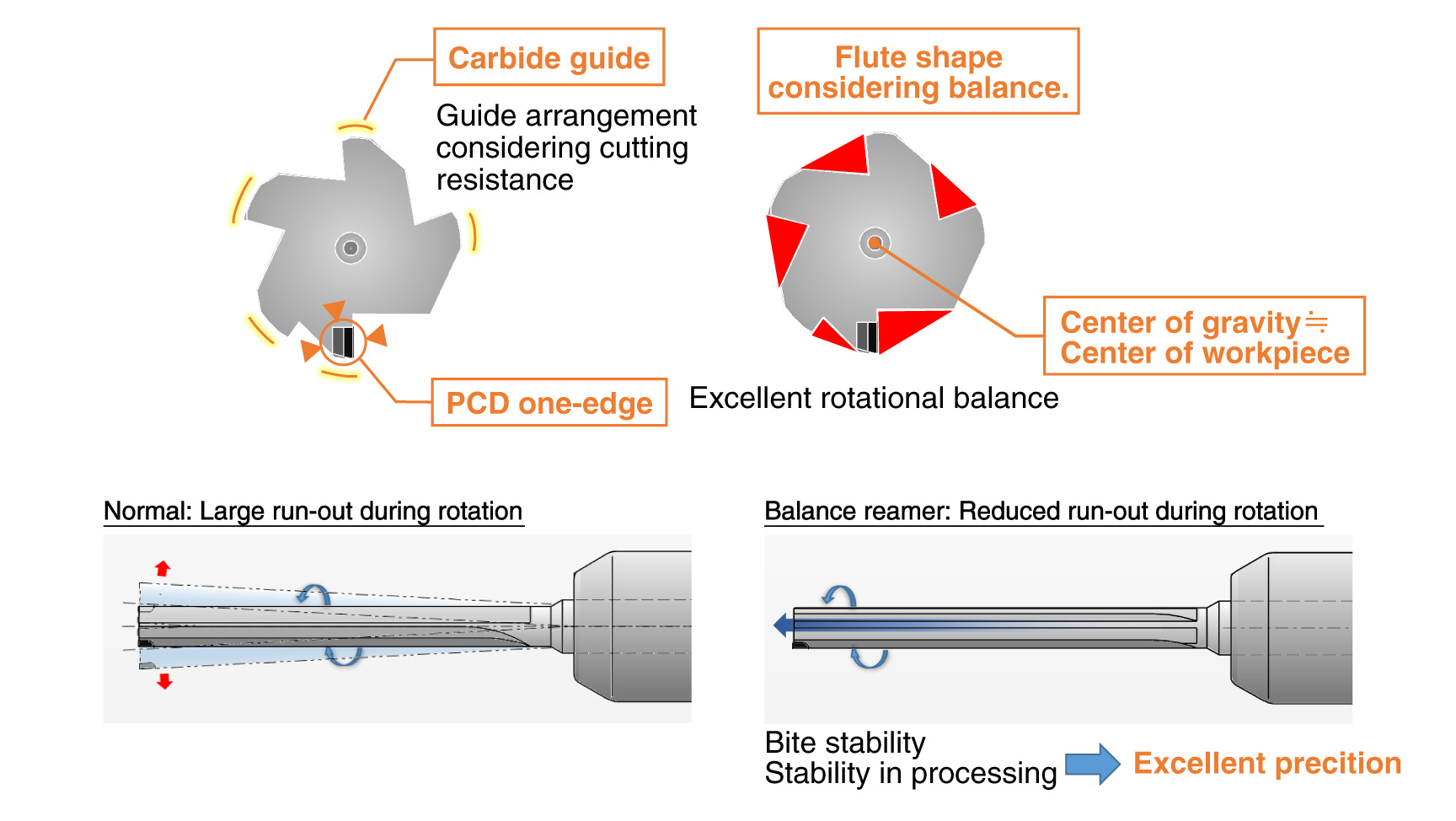

The balanced reamer consists of a 4-point guide pad + 1 PCD edge.

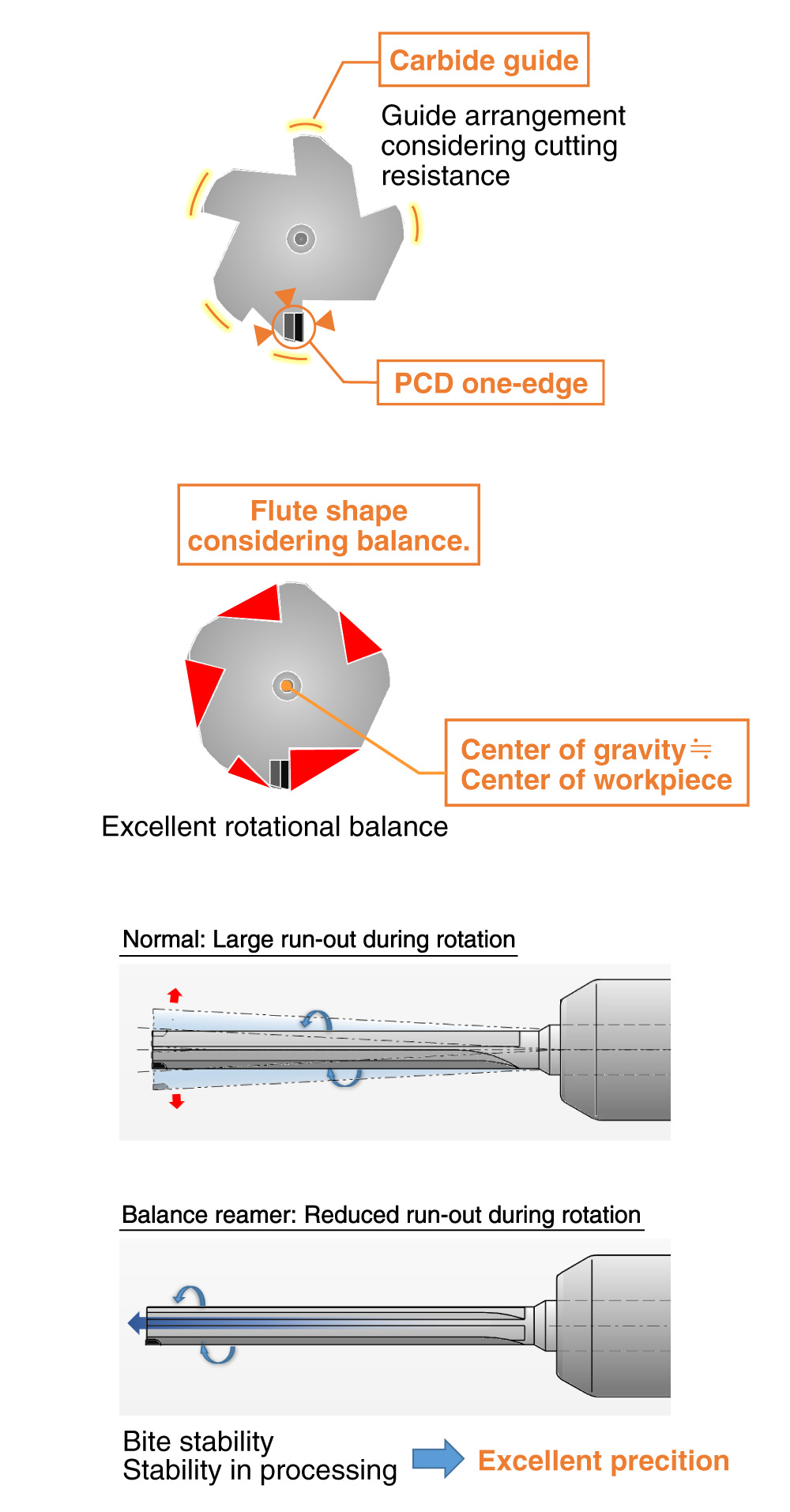

Flute design considering the rotational balance of the reamer suppresses run-out during rotation even when the tool protrusion is long. Guide arrangement considering cutting resistance realises ‘high precision machining’ in deep hole drilling.

Special coolant hole design ensures lubrication during cutting and prevents workpiece damage.

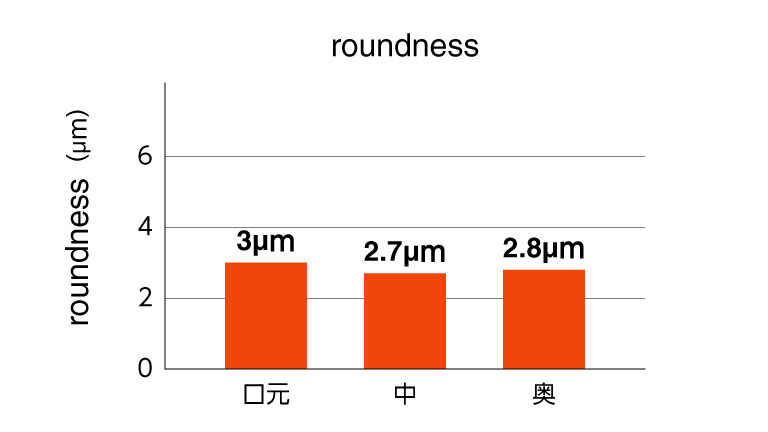

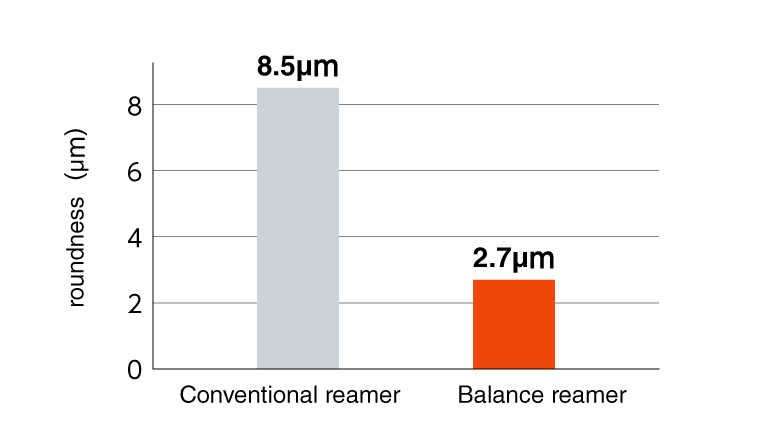

Excellent roundnessGood !

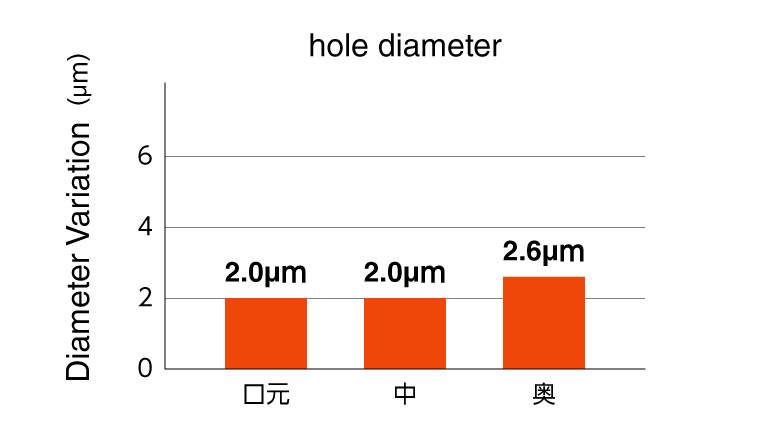

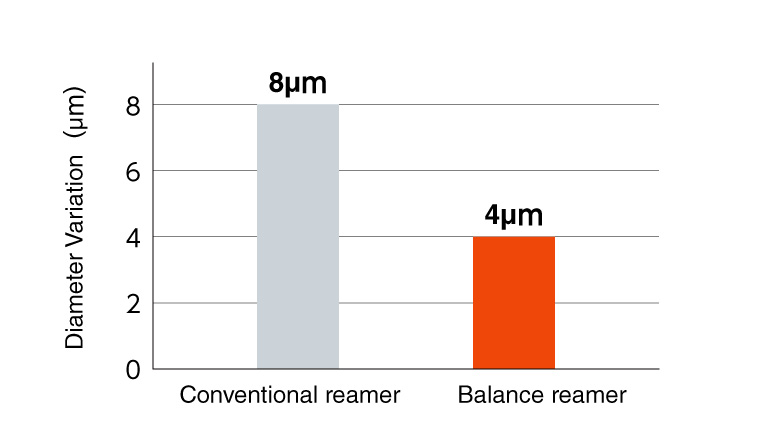

Stable hole diameterGood !

POINT!

Optimum guide arrangement and outstanding rotational balance achieve high precision.Excellent !

POINT!

Special coolant design prevents workpiece damage.Excellent !

Background / Point for Development

Background

- In deep hole drilling, the tool protrusion is longer, resulting in a large rotational balance (misalignment of the cenere of gravity), and the centrifugal force during rotation causes the tool to behave, resulting in unstable machining accuracy.

In addition, insufficient coolant supply to the guide section caused welding and scratches on the workpiece surface.

Point for Development

- The ‘Balance Reamer’ uses a special flute shape with balanced rotation to suppress run-out during rotation and an optimized guide pad arrangement to stabilize the machining accuracy of deep hole drilling.

Furthermore, by supplying coolant to the entire guide, the lubricity is improved, which prevents welding to the guide and scratches on the workpiece surface.

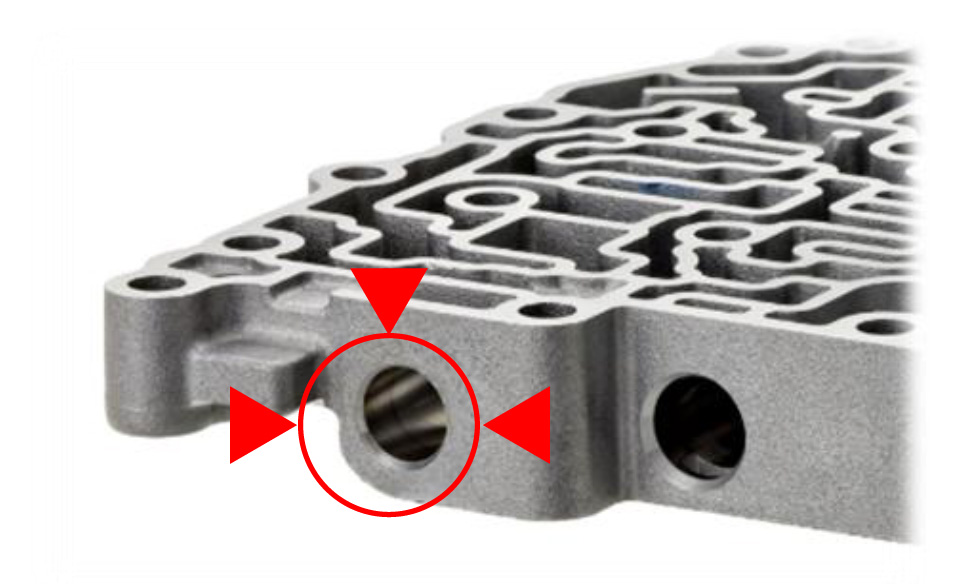

ExampleDeep hole

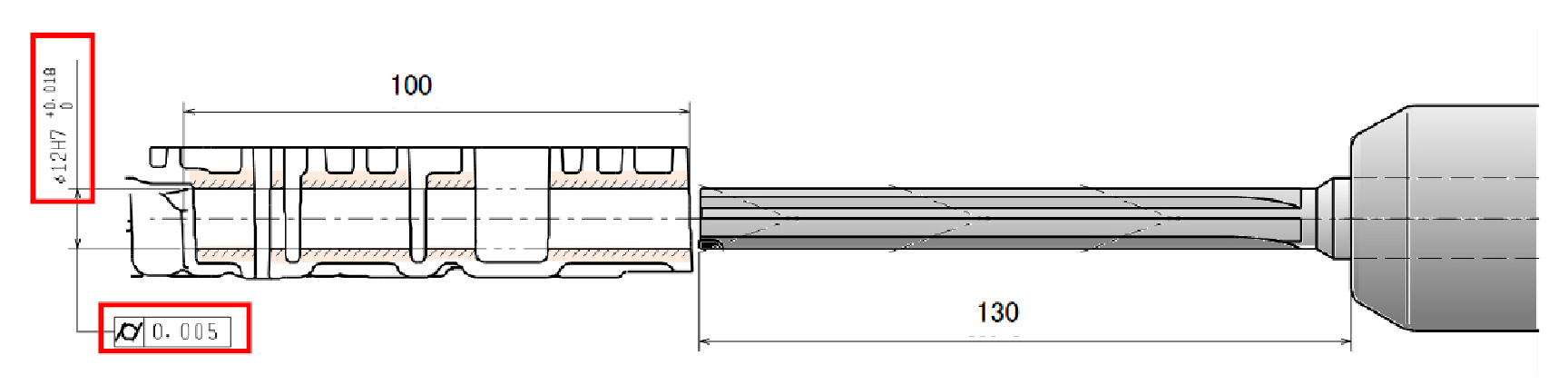

| Tool | Balance reamer |

|---|---|

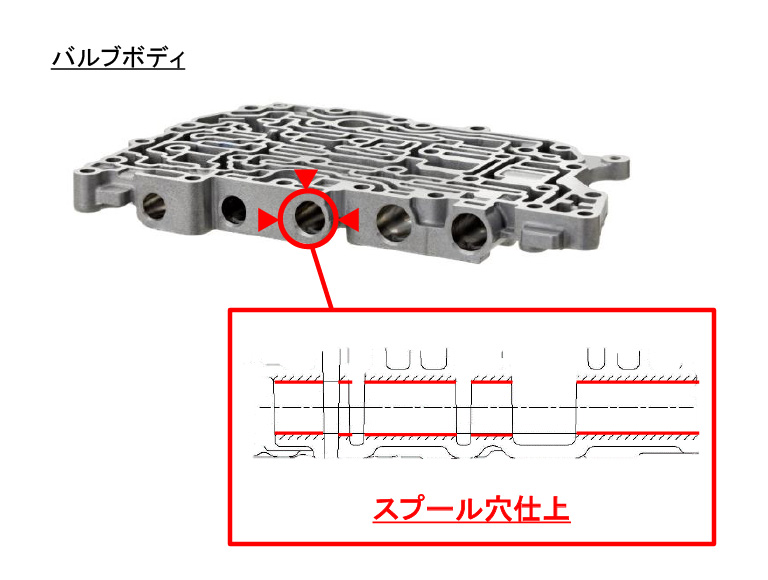

| Workpiece | Valve body / Spool hole |

| Material | ADC12 |

| Tool Diameter | ø12 |

| Cutting Conditions |

|

| Cutting allowance |

ø0.25 |

| Required accuracy |  |

|---|

Cylindricity

Hole Diameter

Product Specification

Tool Specification

| Process covered |

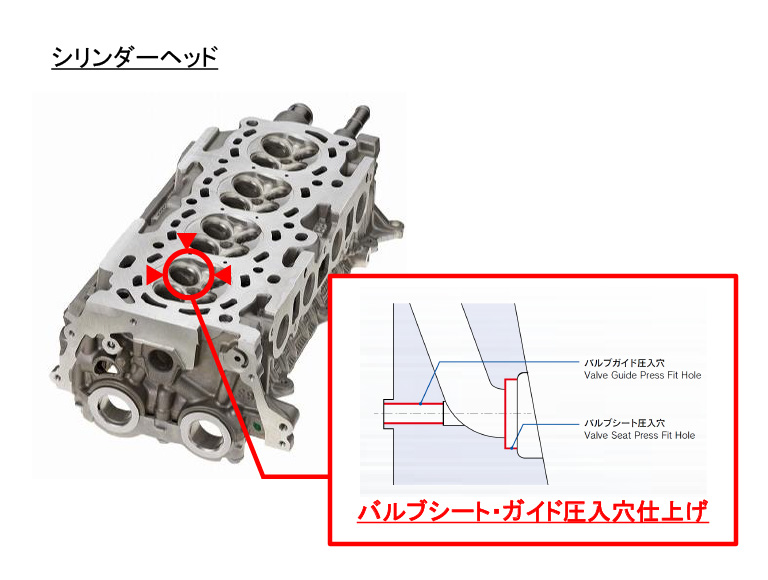

バルブシート・ガイド圧入穴、スプール穴 |

|---|---|

| Diameter | ø8~ |

| Standard conditions |

|

| Performance | 加工径:IT7級 |

適用ワーク形状