BJGF Drill

Hole accuracy : IT8

Carbide drill for one-shot

machining of cast iron!

- Excellent machining with

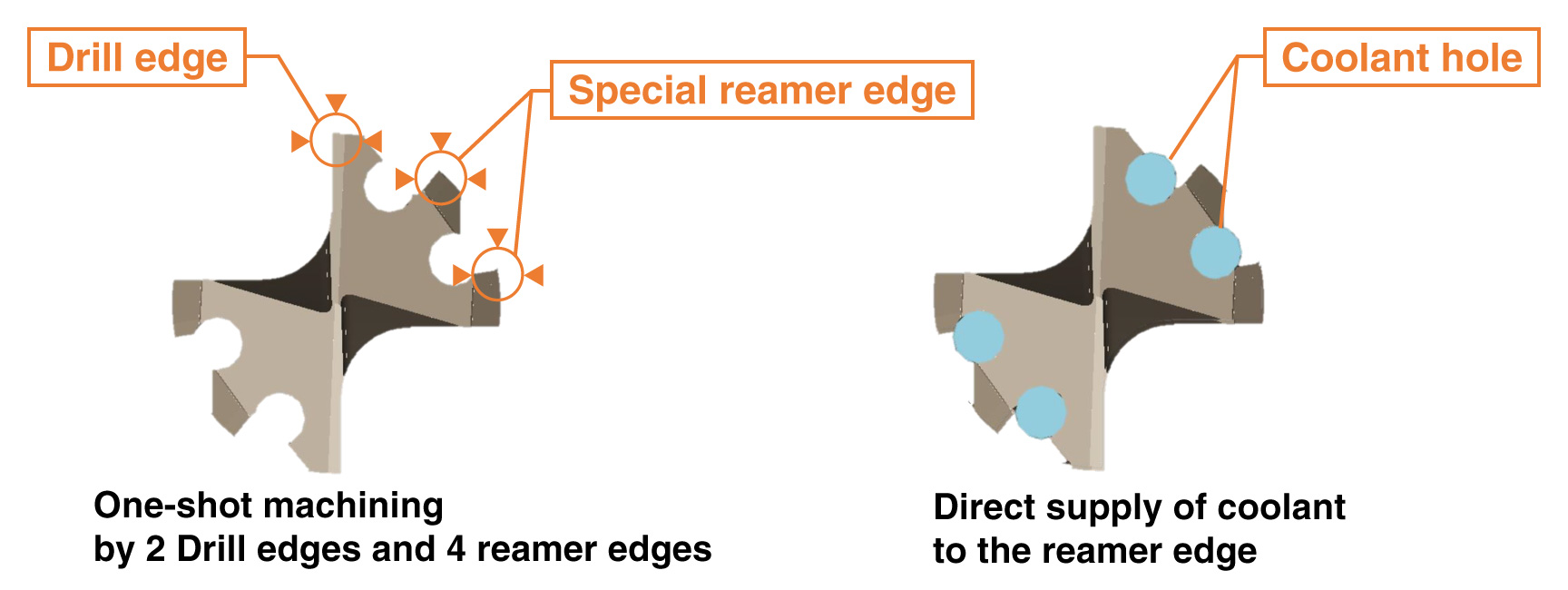

“drill edges+ 4 special reamer edges”

- IT8-class hole one-shot finishing

- Excellent surface finish

- Long life with coatings for hard materials

![]()

“Amazing Ideas / Facts!”

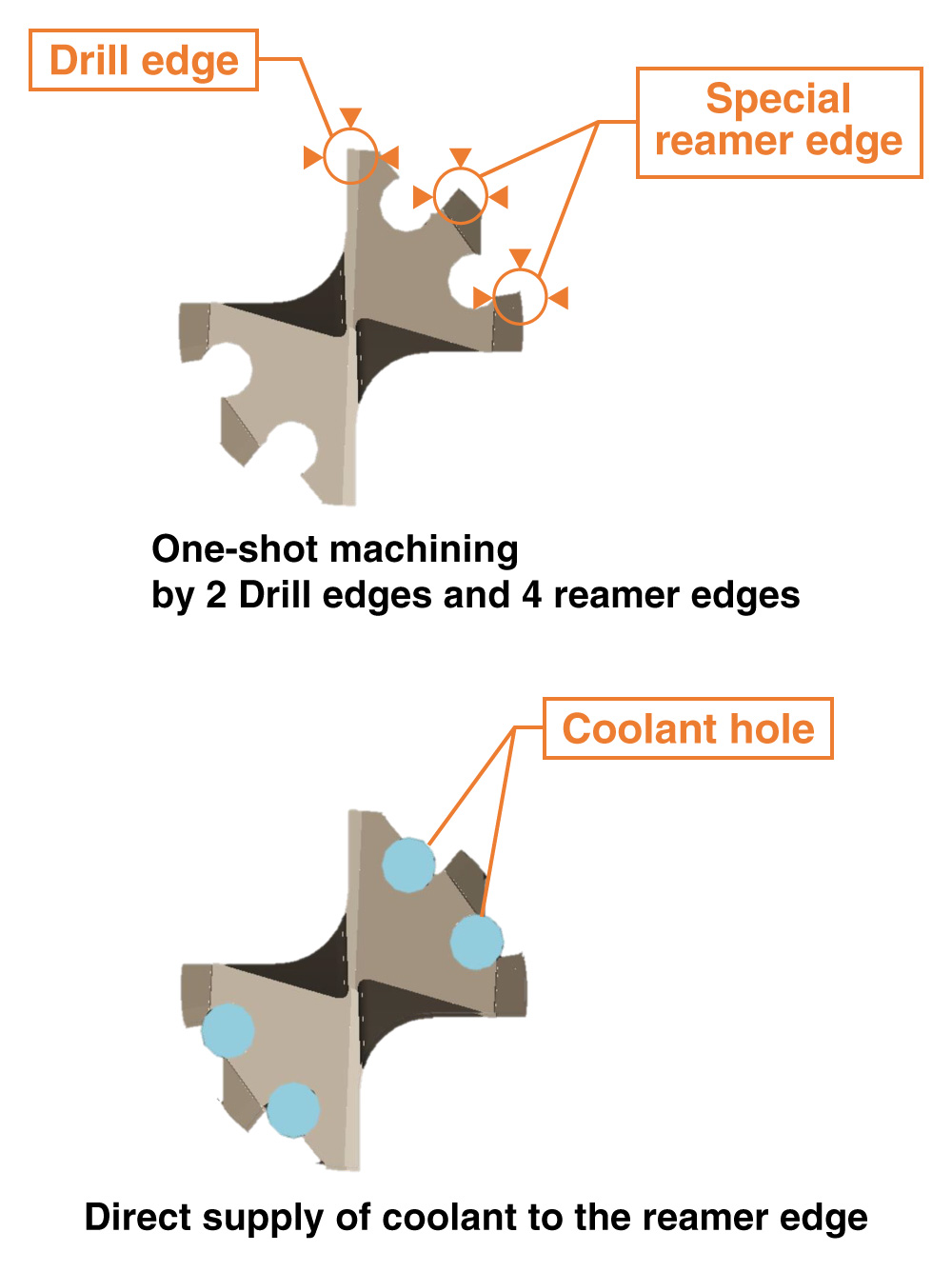

The BJGF drill consists of “2 drill edges + 4 burnishing reamer edges”.

- High rigidity and high precision machining

- “Back jet coolant” for superior cooling & chip evacuation : excellent surface finish

- “Multi layered coating” extends tool life & one shot finishing of cast iron

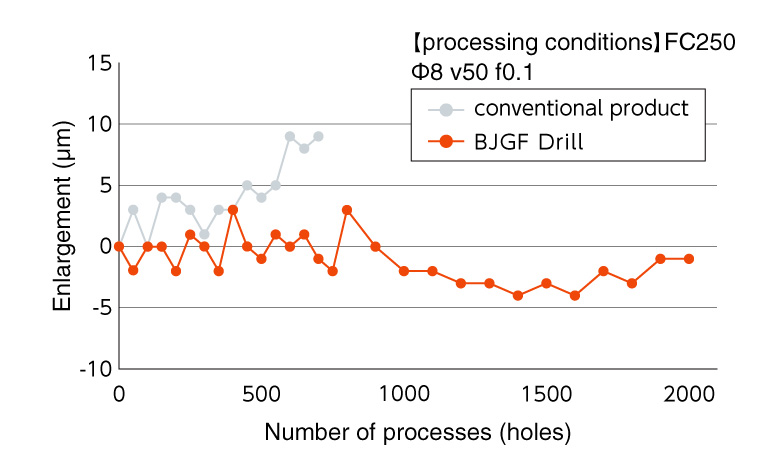

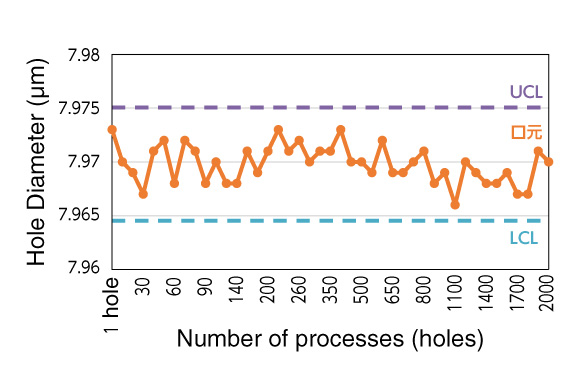

IT8-class hole diameter accuracyGood !

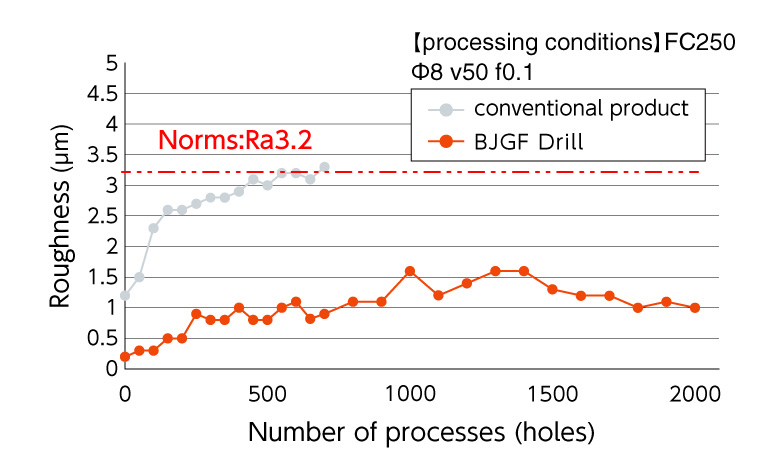

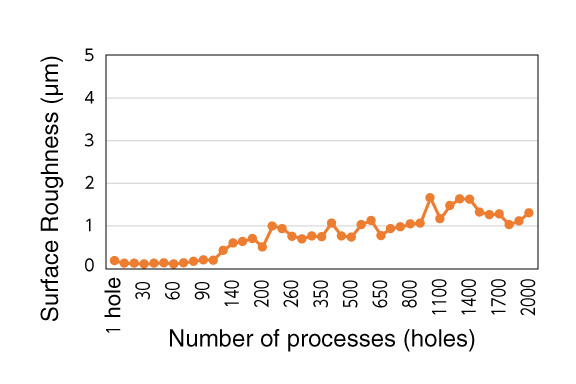

Excellent surface roughnessGood !

POINT!

Dividing the role of the cutting edge by functionExcellent !

Background / Point for Development

Background

- Although “One-shot drill” has been developed to improve productivity in the machining of cast iron, the built-up on reamer edges caused bad surface finish.

Point for Development

- “Back-Jet-Coolant” has successfully improved the cooling efficiency on the cutting edges and the chip evacuation.

Reduced built-up edges that had caused bad surface finish.

Multi layered coating for hard materials has significantly reduced edge wear, hence longer tool life.

Example

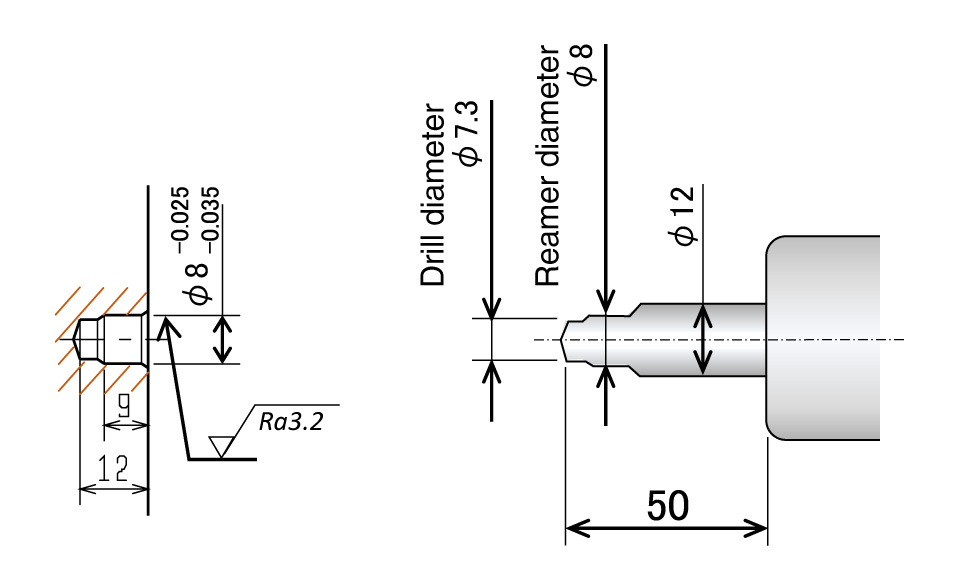

| Tool | BJGF drill |

|---|---|

| Workpiece | Test piece |

| Material | FC250 |

| Tool Diameter | ø8mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

Hole Diameter

Surface Roughness

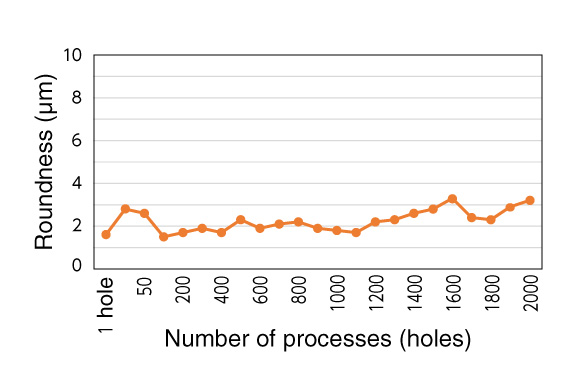

Changes in roundness

Product Specification

Tool Specification

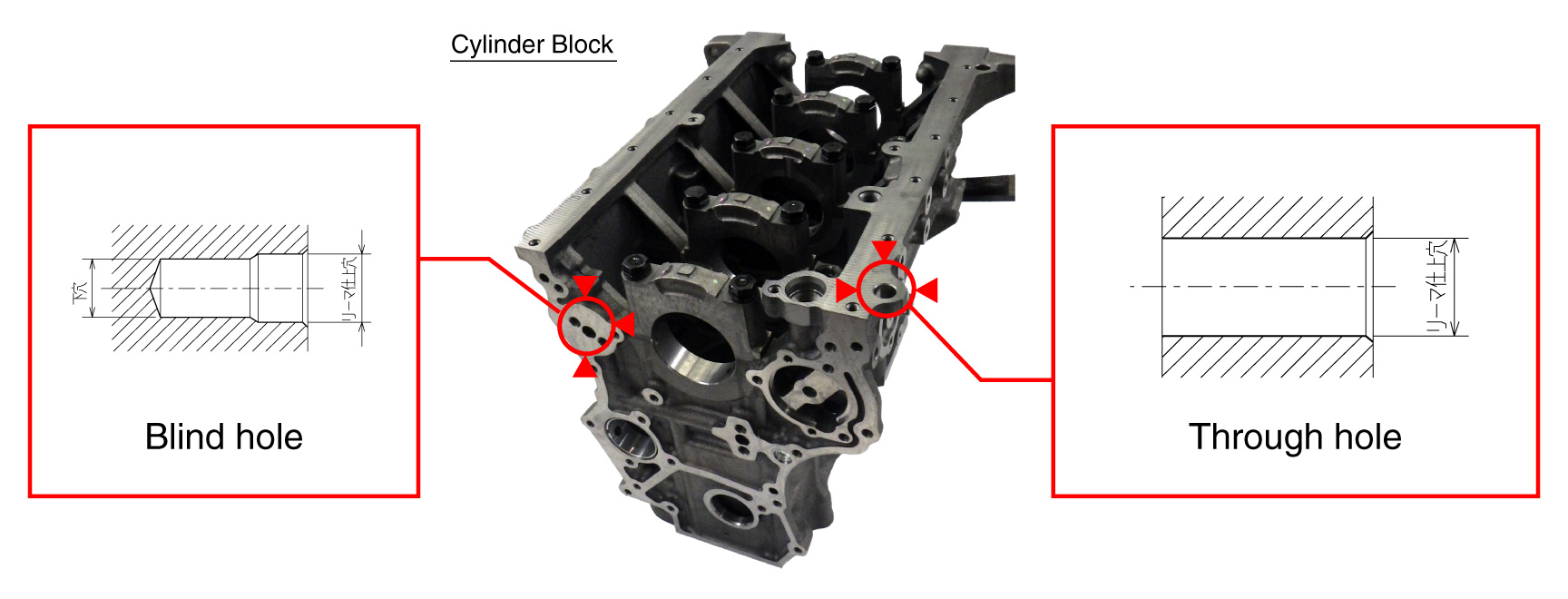

| Process covered | knock holes, high precision hole |

|---|---|

| Diameter | ø6 - 20 |

| Standard conditions |

|

| Performance | Precision: IT8 Roughness: ≤ Rz12.5 (≤ Ra3.2) Roundness: 10µm |

Example of applicable work