Damper HolderPAT.P

For those who are suffering

from chatter caused by vibration!

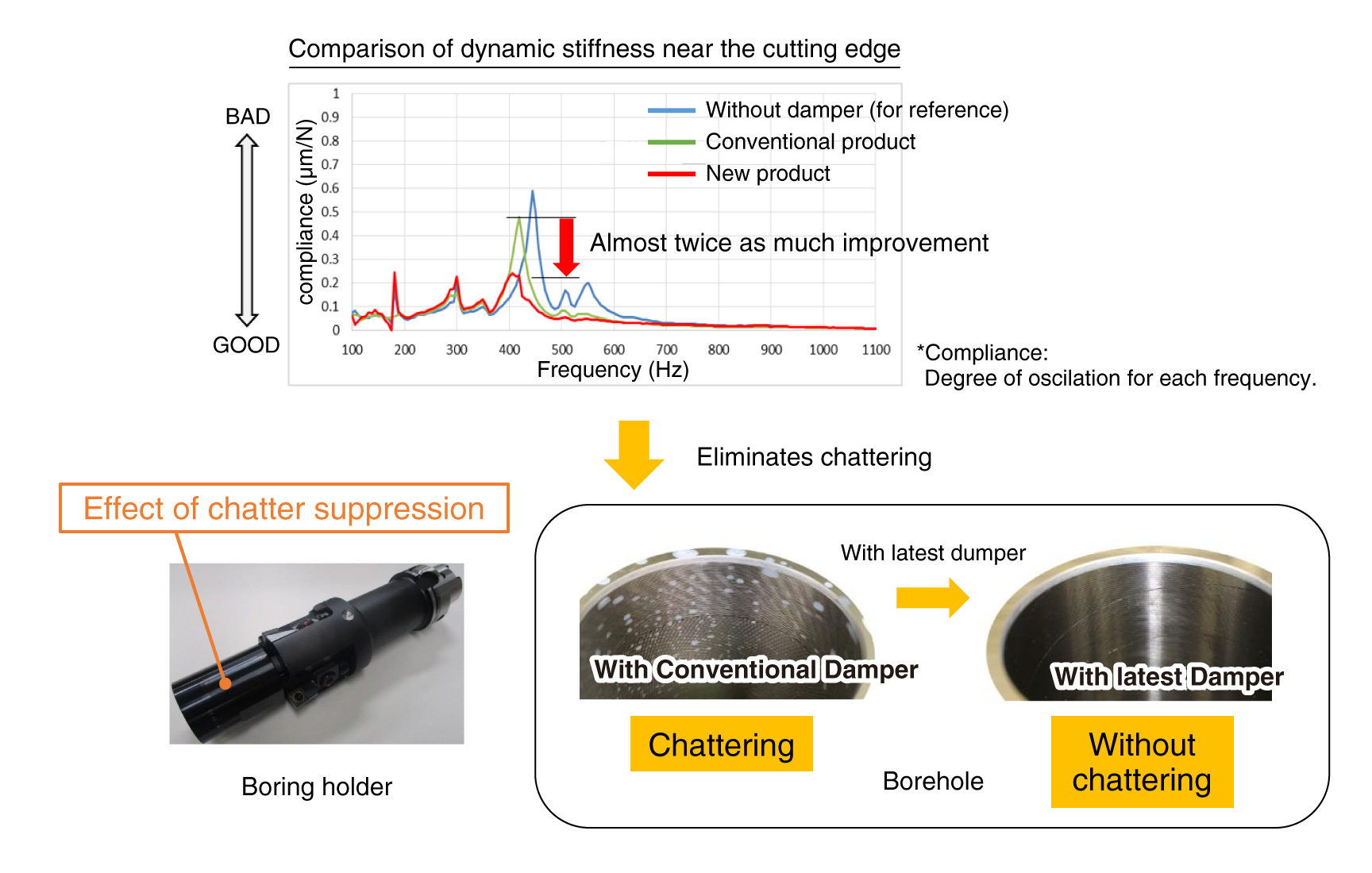

- High damping capacity of the damper matched to the vibration characteristics solves processing chatter!

- High damping performance due to dedicated design to suit the equipment/tools used.

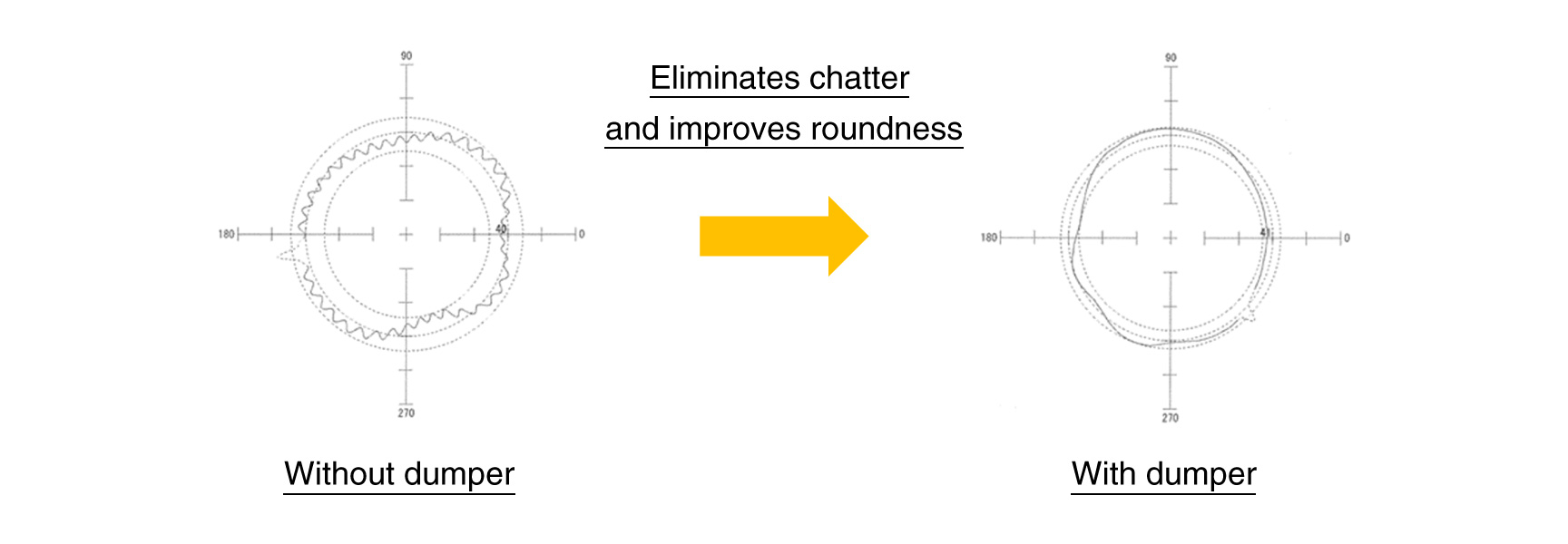

- Stable quality due to improved machining accuracy.

- Reduced investment due to highly efficient machining.

![]()

“Amazing Ideas / Facts!”

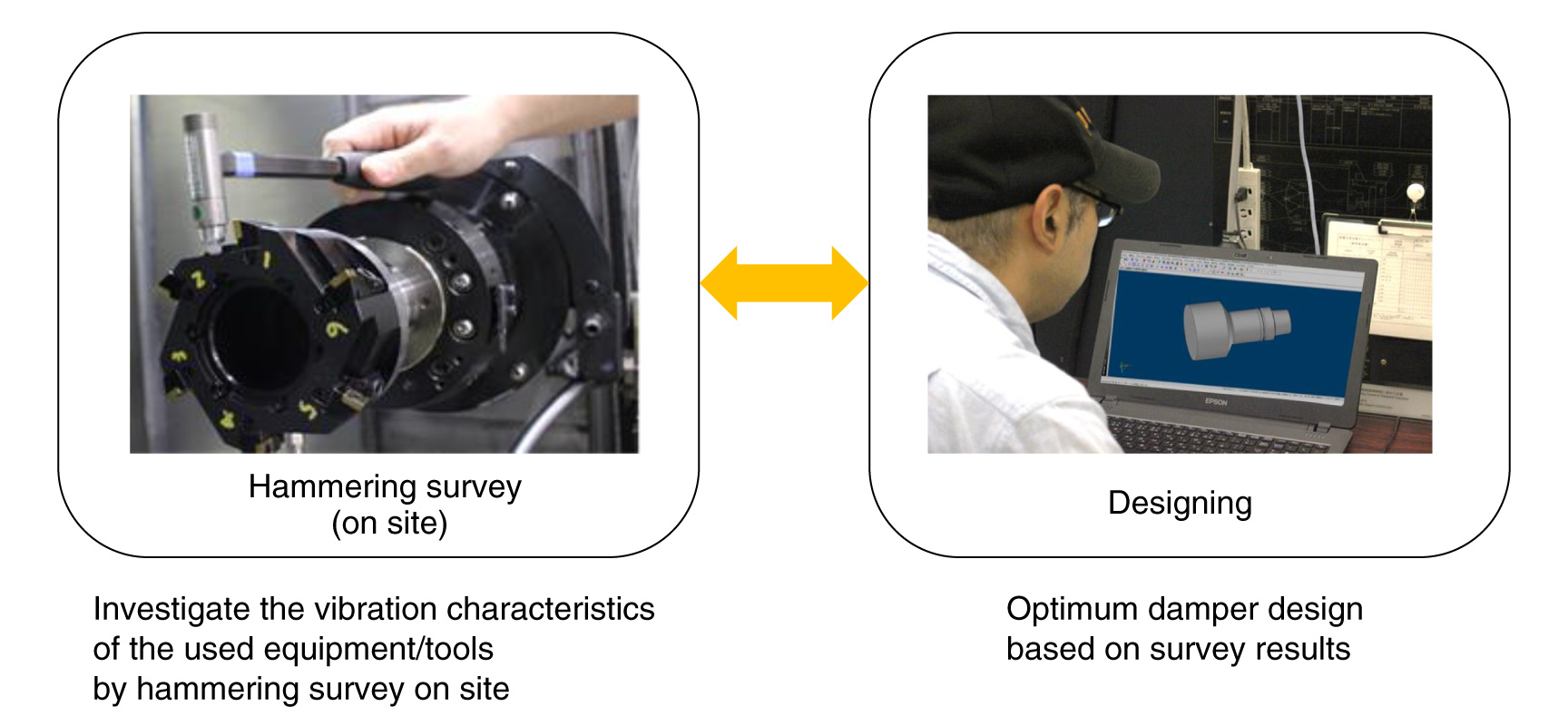

Vibration analysis of equipment / tools in use on site (For more information, see “Services: Vibration Diagnostic Services”).

Optimum damper design through preliminary hammering surveys maximizes the damping effect.

Machining chatter is resolved, enabling improved machining efficiency and quality.

POINT!

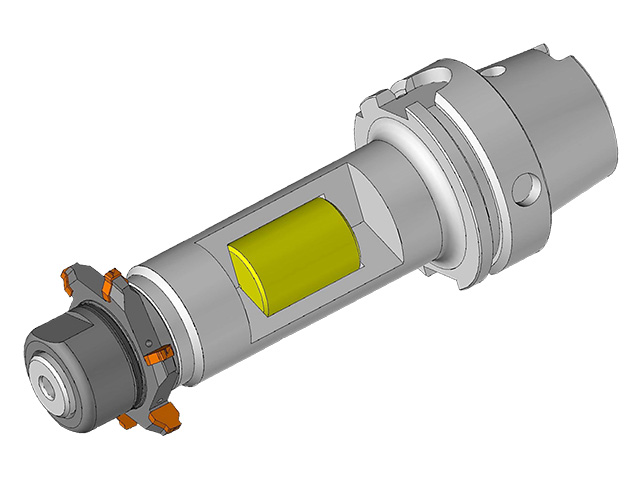

Optimum latest damper design for the tool.Excellent !

Effect of chatter suppressionGood !

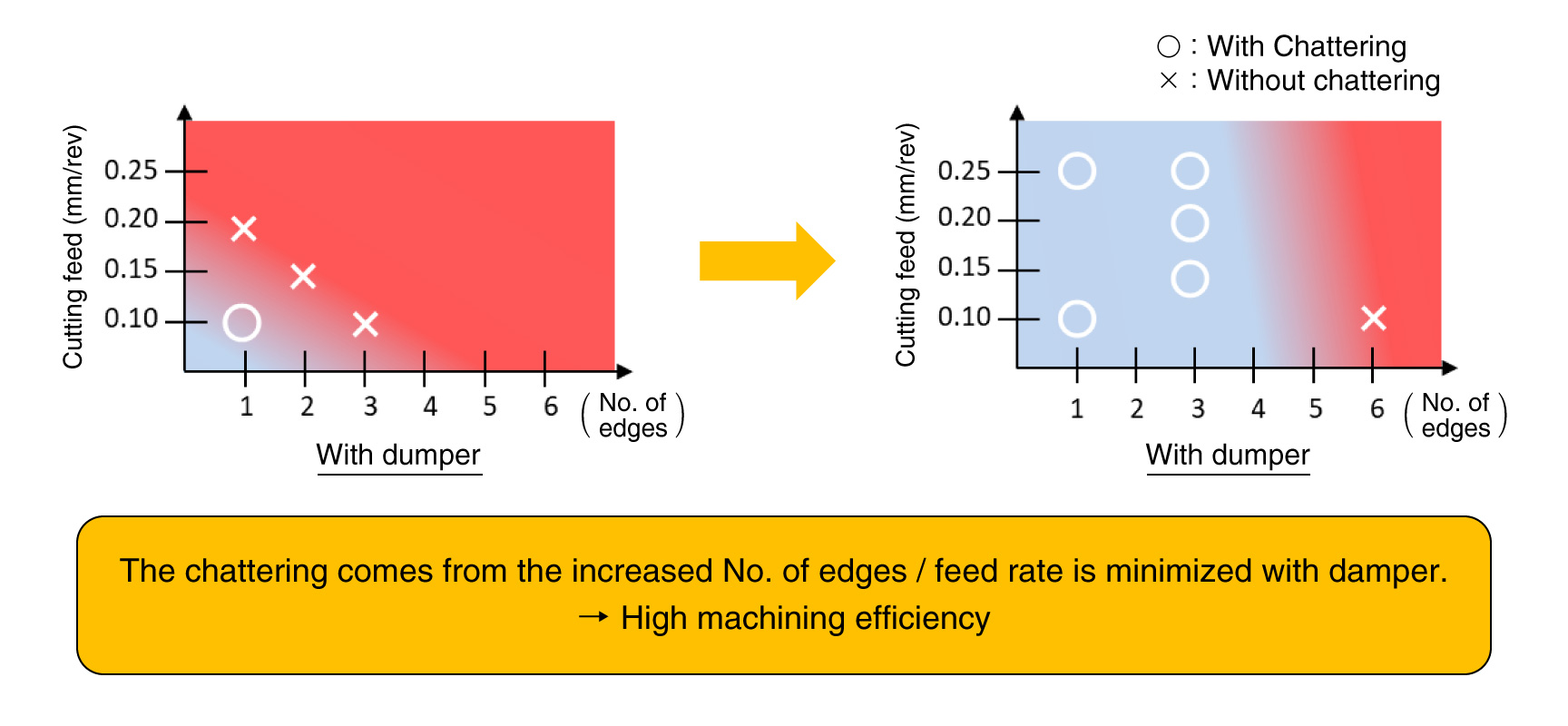

High efficiency with the use of damperGood !

| Material | S45C |

|---|---|

| Tool Diameter | ø115mm |

| Cutting Conditions |

|

| No. of edges | 1 - 6 |

| Allowance | ø0.4 |

Background / Point for Development

Background

- More demands for high efficiency in hard-to-cut materials and lengthy machining in the recent diversification & generalization of product types.

- Chattering from the machining often causes deteriorating accuracy, damaging cutting edges, and prolonging cycle time.

Point for Development

- The holder designed with an optimum damping effect to suit the equipment and the used tools.

- Damped vibration (oscillation)

- Improved machining accuracy & efficiency

- Longer tool life due to non-chattering edges

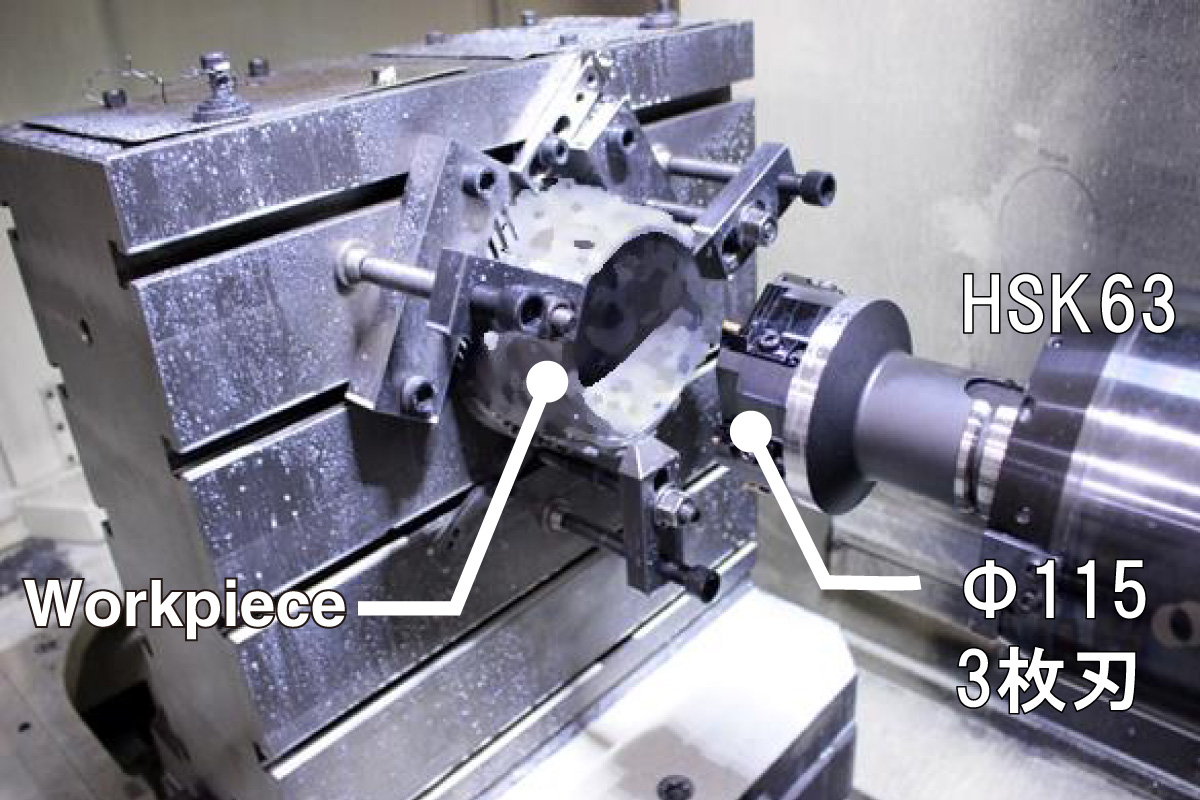

Example

| Material | S45C |

|---|---|

| Tool Diameter | ø115mm |

| Cutting Conditions |

|

| No. of edges | 3 |

| Allowance | ø0.4 |

Product Specification

Tool Specification

| Applicable work | No restrictions on workpiece material |

|---|---|

| Coolant | Internal supply possible |

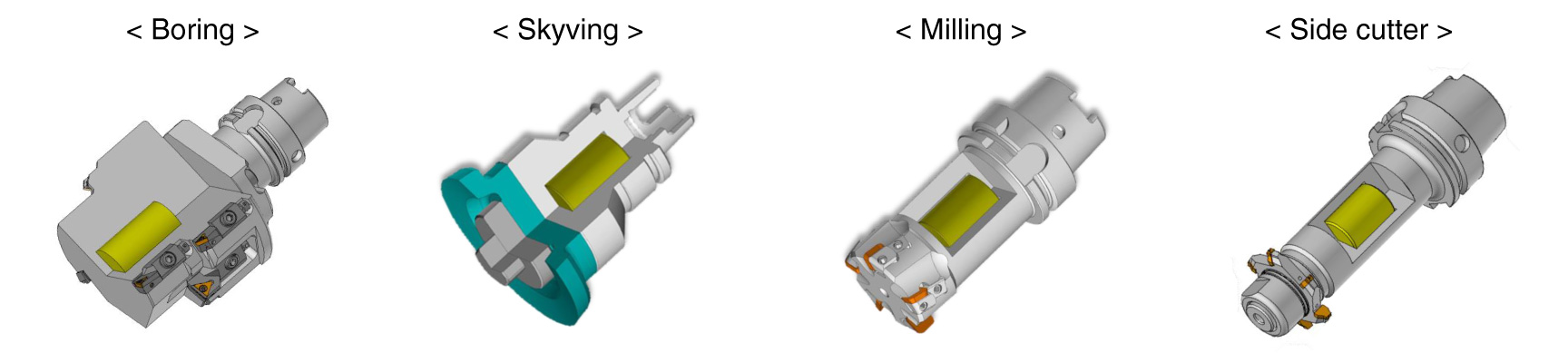

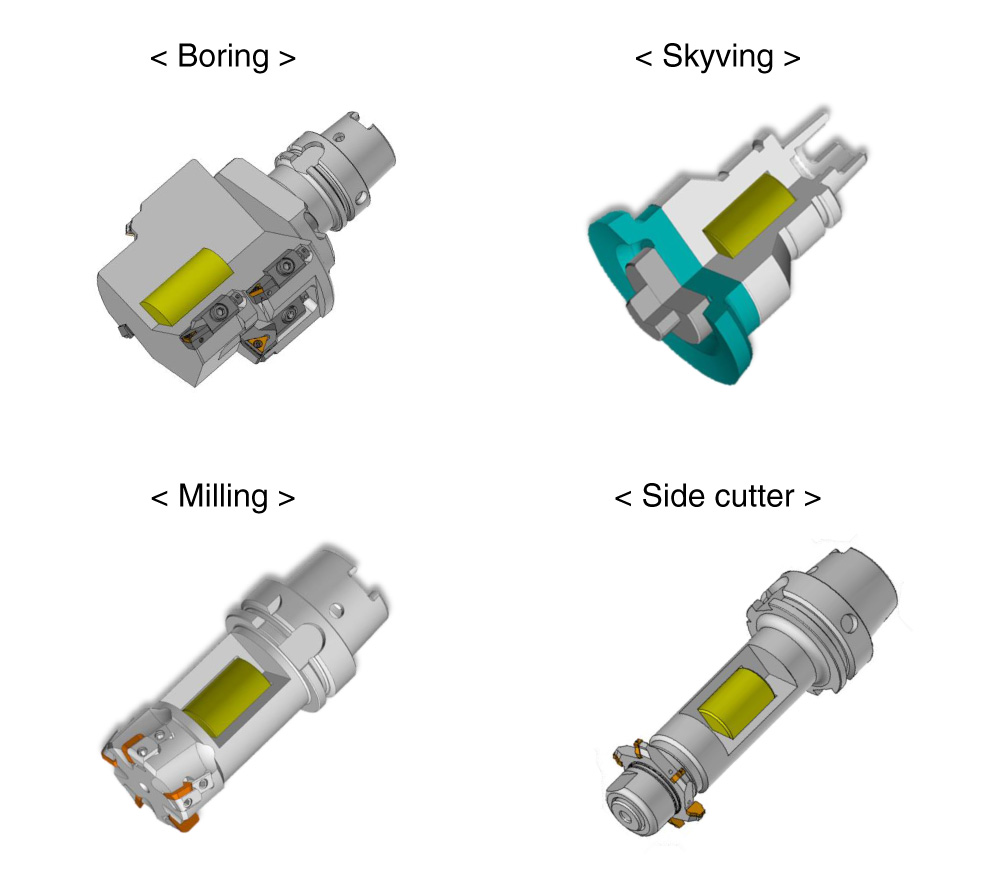

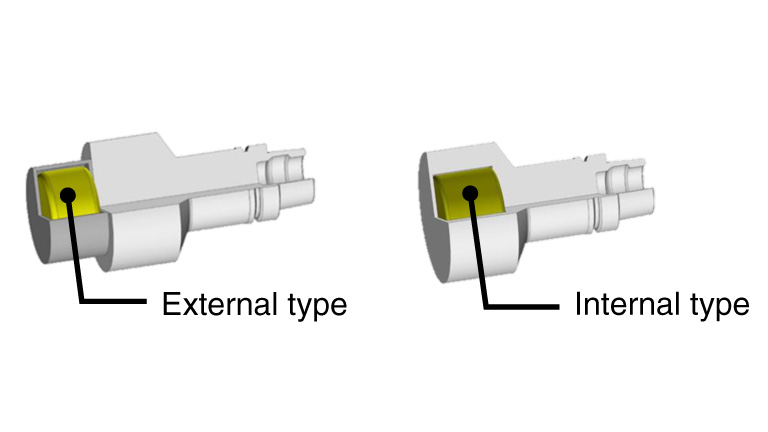

External/internal mounting of dampers available according to the specific tool geometry, weight limitations, and workpiece interference, etc.

Example