D-Cut Tool

Helical machining for any holes!

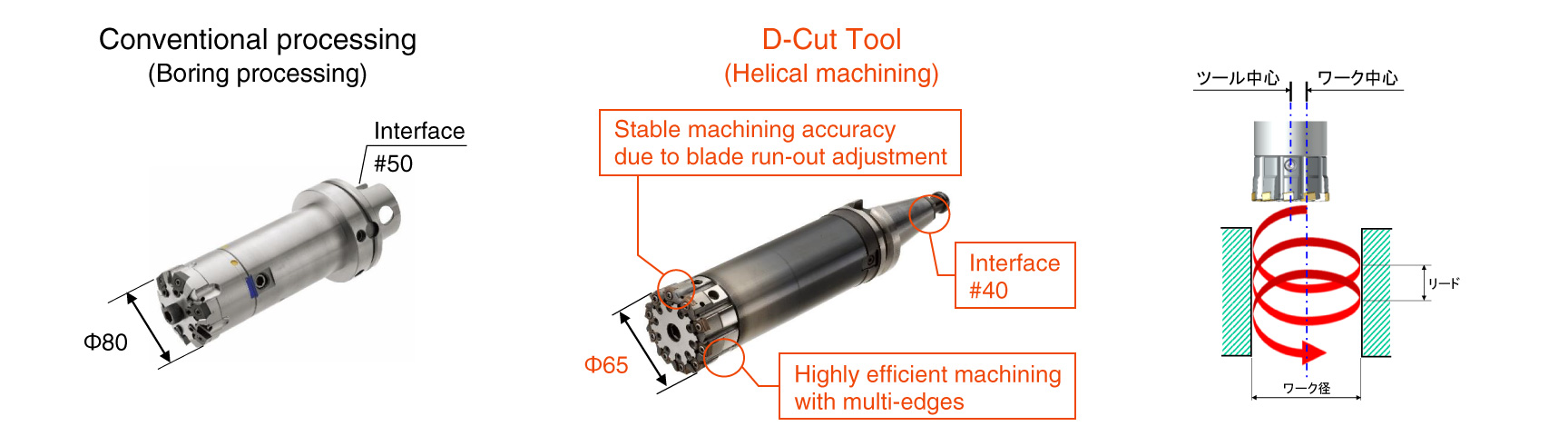

- Special cutting-edge design enables helical machining, suitable for multi-product production.

- Applicable to various hole diameters

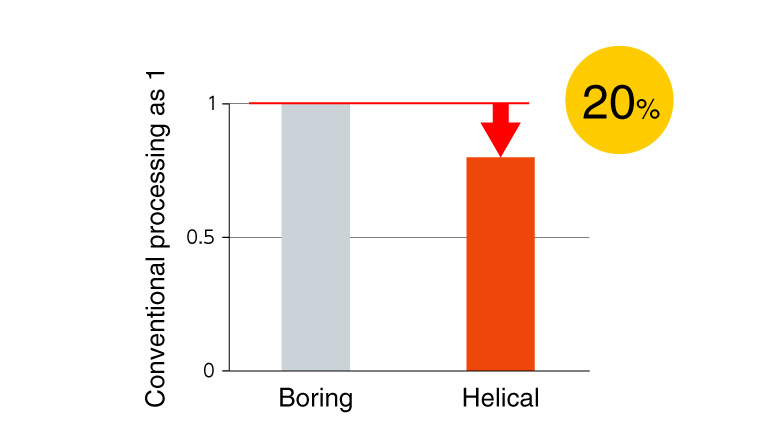

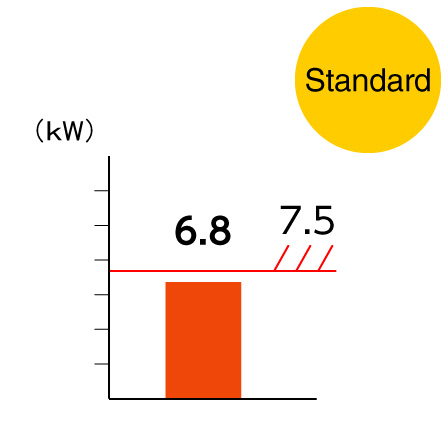

- 20% reduction in power consumption due to low cutting resistance

- Reduced spindle power for downsizing

![]()

“Amazing Ideas / Facts!”

Because of its helical machining, the D-Cut Tool can be used for various hole diameters.

High-speed machining with the most suitable cutting-edge (material).

Multi-edges + its unique edge run-out adjustment mechanism enable low cutting resistance.

Reduced spindle load results in spindle downsizing (e.g. from conventional roughing Bo equipment #50 to #40!).

POINT!

Helical machining to unify toolsExcellent !

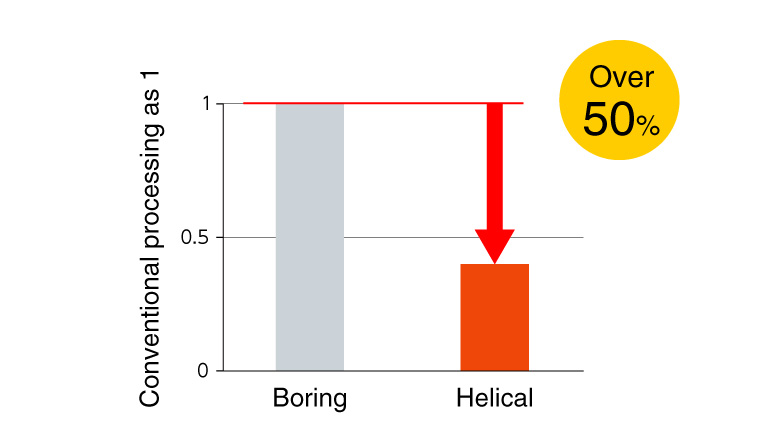

Reduction of cutting resistance (torque)Good !

Reduction of power usageGood !

Background / Point for Development

Background

- Increasing needs for multi-product production (at manufacturing sites).

- Work pieces with different diameters require each different tools which increase the need for further investments.

Point for Development

- With “D-cut tool”, various different cutting diameters can be processed with just one tool.

- The unique cutting-edge design & edge run-out adjustment mechanism enable low-resistance machining, which results in ‘cost reduction’ and ‘equipment downsizing’.

Example

| Equipment | BT40 Vertical type |

|---|---|

| Material | Centrifugal cast iron |

| Tool Diameter | ø65mm |

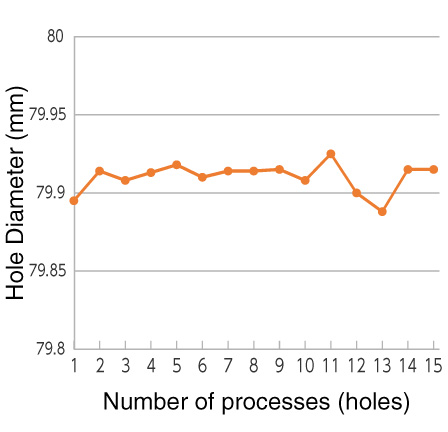

| Machining diameter | ø79.9 ± 0.1 |

| Cutting length | 135mm |

| Allowance | 3.2mm |

Cutting Conditions (Cutting time 23s)

| Revolution of spindle | N=3,250min-1 |

|---|---|

| Cutting feed | f=1.6mm/rev |

| Lead | 3.5mm |

| contouring radius | 7.45mm |

| Coolant | Dry |

Hole Diameter

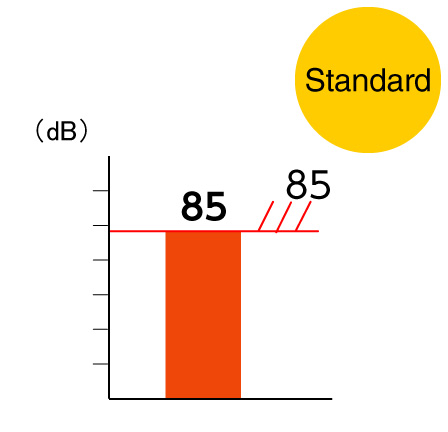

Cutting sound

spindle power

Product Specification

Tool Specification

| Tool diameter × number of edges |

Hole diameter |

Insert material |

|---|---|---|

| ø55 × 8 | ø65 - | Ceramic for Cast Iron Carbide + DLC for Aluminum |

| ø65 × 10 | ø75 - | |

| ø85 × 12 | ø95 - |

Standard cutting conditions will be proposed based on the workpiece diameter, cutting length and required machining time.

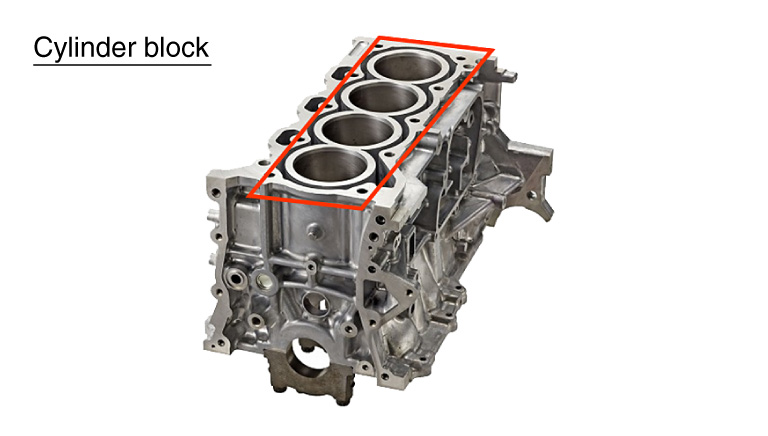

Example of applicable work

Cylinder block, Cylinder bore hole roughing,

Transaxle case, Main bore roughing