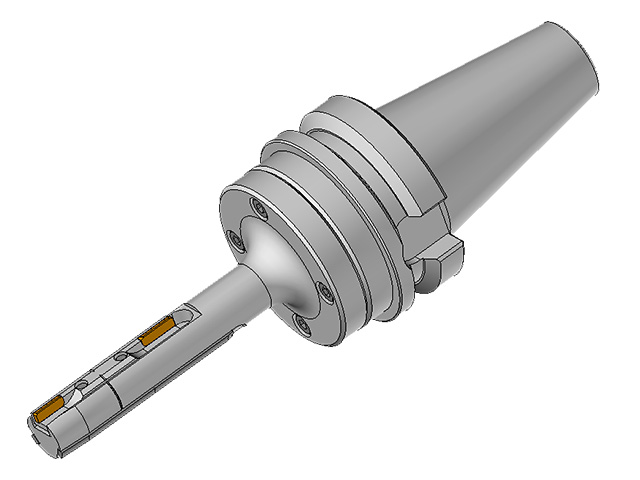

Spring type deburring tool

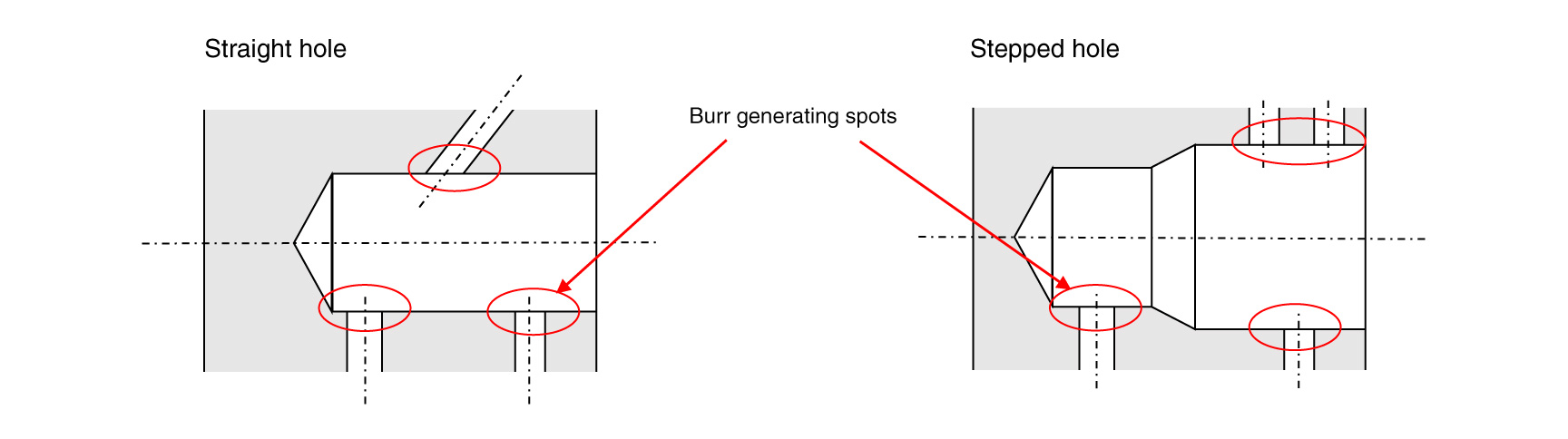

for cross holes

Deburring tools from

special tool manufacturers

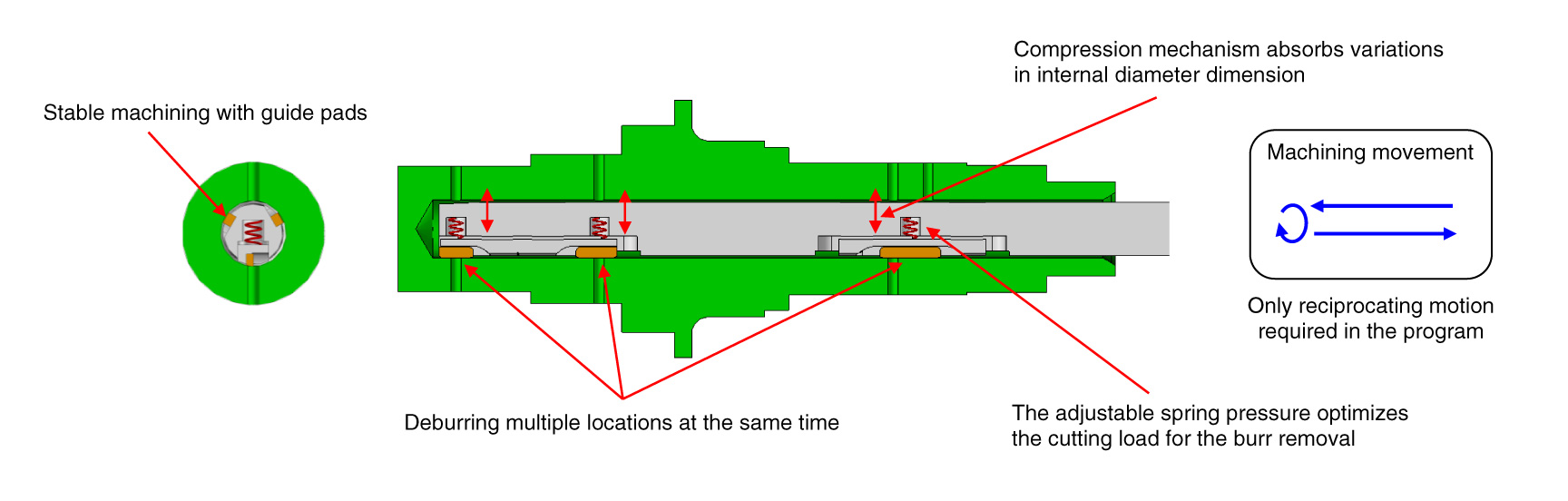

- Optimal cutting edge and compression mechanism remove cross-hole burrs quickly,

successfully, and cleanly

- Simultaneous processing of multiple cross holes.

- The compression mechanism allows the effective burr removal.

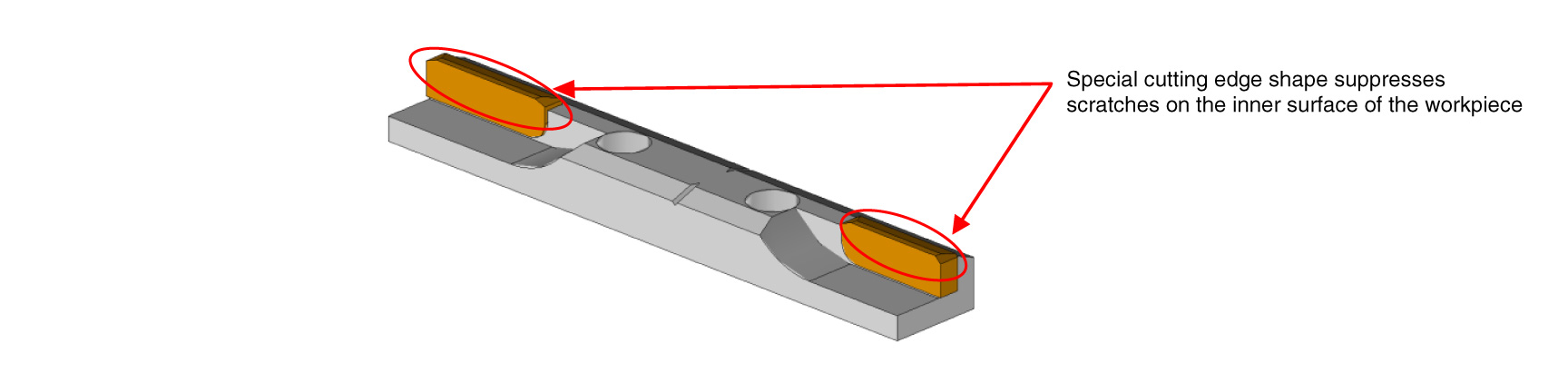

- Special cutting edge shape prevents scratches on the inner diameter surface.

“Amazing Ideas / Facts!”

The spring-type deburring holder has a specially shaped cutting edge and a built-in compression mechanism.

Contributes to reducing cycle time by responding to variations in workpiece inner diameter dimensions and removing burrs from multiple holes at the same time.

In addition, the guide pad provides stable deburring cutting performance.

POINT!

Structure of spring type deburring holderExcellent !

Cutting edge shape

Background / Point for Development

Background

- Deburring of cross-holes on shafts, etc. was usually done by hand or by NC machine, using brush or cutter, which was time consuming.

- During brush / cutter often lead the problems of burr remaining due to the variations in the inner diameter of the workpiece.

Point for Development

- The spring pressurized deburring holder, with special cutting edge shape and with compression mechanism, simultaneously removes burrs from multiple holes using only reciprocating motion, reducing cycle time.

Product Specification

Tool Specification

| Process covered |

Shaft (Cross hole) etc. |

|---|---|

| Material | Steel, Cast iron |

| Diameter | ø9 - |

| Standard conditions |

|

Applicable work shape