Segment type

for surface processing

Economic!

Use the brushes to its limits

- Maximizes brush performance.

- Efficient machinability by keeping the brush stiffness

- Overhang adjustment optimizes and reduces tool costs

- Applicable to large sized workpieces

“Amazing Ideas / Facts!”

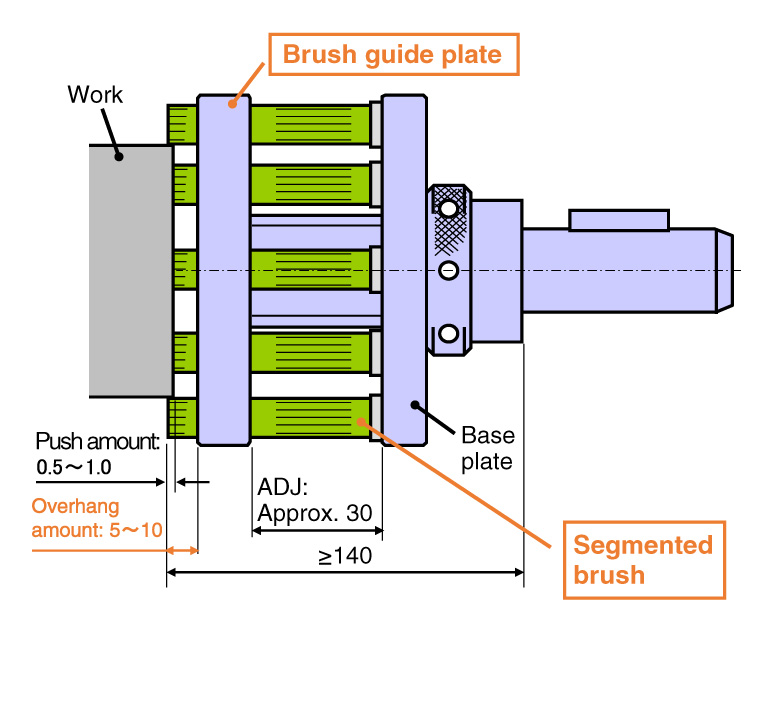

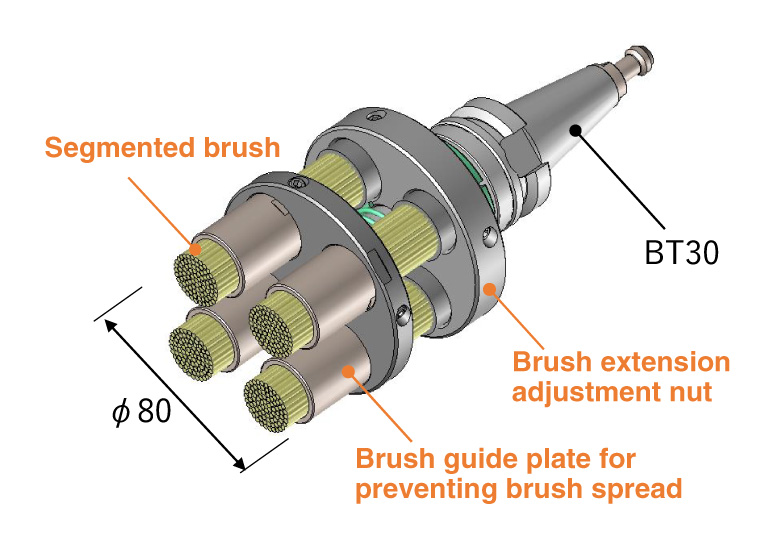

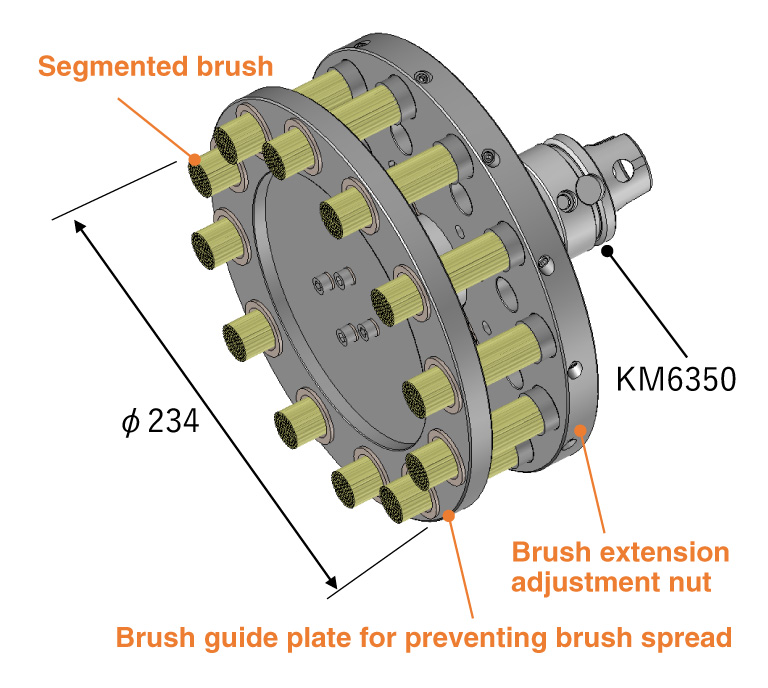

The segment type deburring holder uses “abrasive grain embodied nylon brushes”.

The filament spread can be minimized by the “brush guide plate”, keeping optimal brush strength and thus high deburring performance.

The protrusion (after the tips are worn out) maximizes the brush life and reduces the tool cost, the frequency of tool replacement, improving productivity.

POINT! Brush guide plate suppresses brush movable deflectionExcellent !

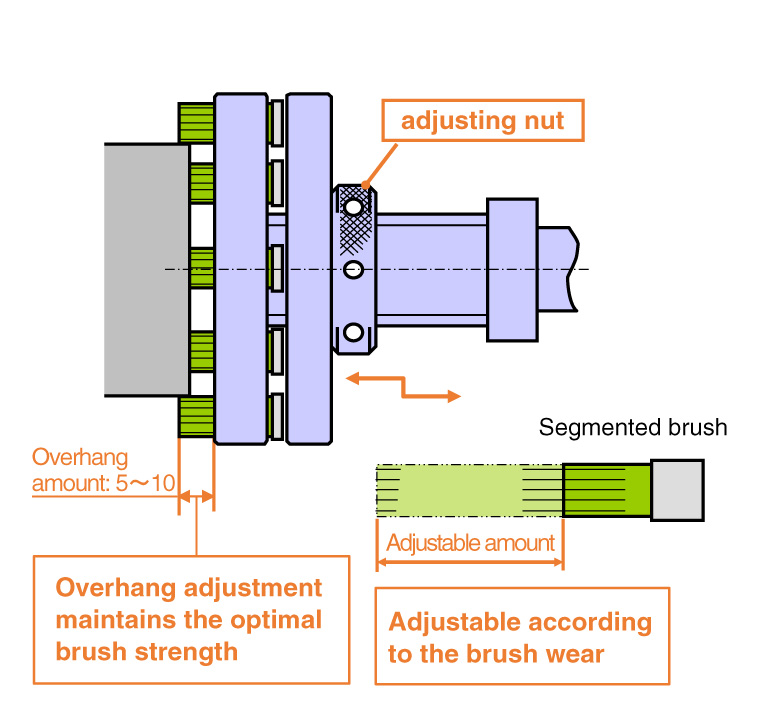

POINT! Pushing out brush tips using the adjusting nutExcellent !

Background / Point for Development

Background

- Conventional cup brushes often face difficulties of non-efficient performance, due to the filament wear and the spread of bristles by centrifugal force.

- When the workpiece surface is wide, More machining time is required with small diameter cup brushes.

Point for Development

- With the brush guide plate, the segment type brush holder keeps constant stiffness of brush tips, resulting in an excellent cutting performance.

- Once the tips wear out, the overhang can easily be adjusted, fully utilizing the brush life, reducing the tool cost and the brush replacement frequency.

- Large-diameter brush holder reduces machining time for workpieces with large machining surfaces.

Example

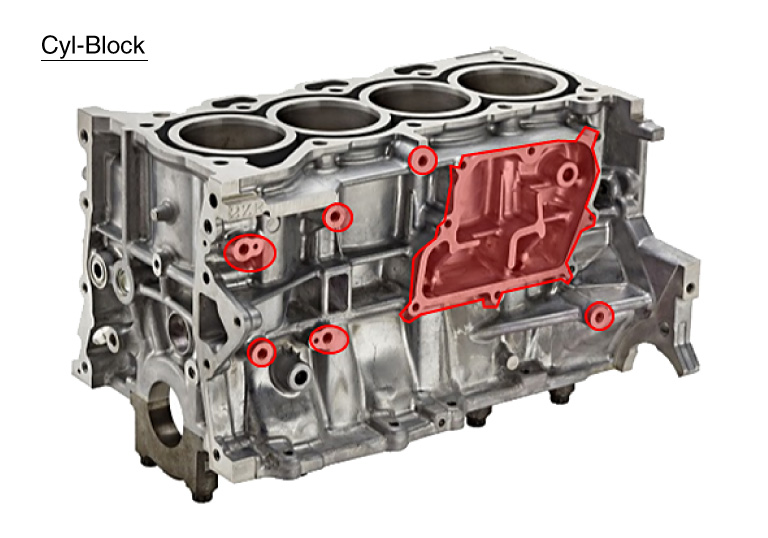

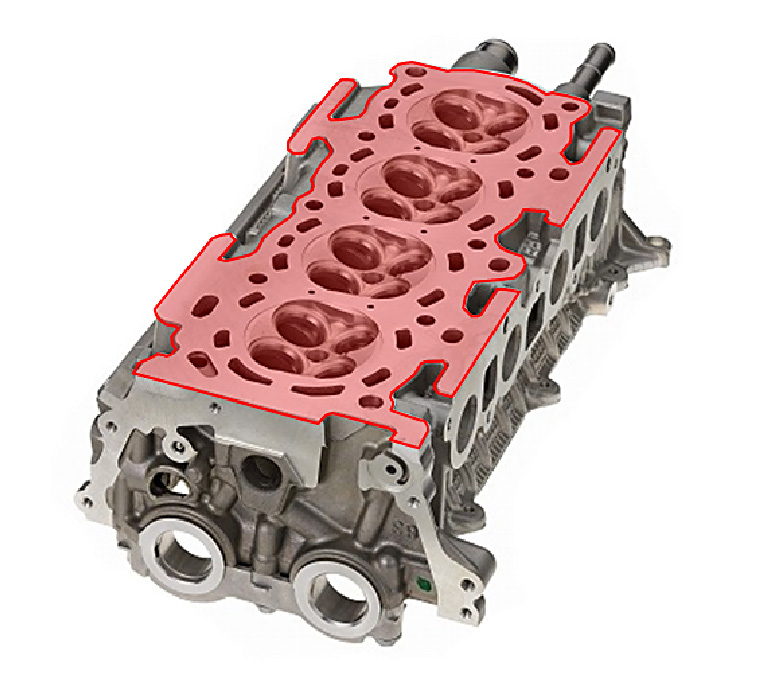

| Workpiece | Cyl-Block (side) |

|---|---|

| Material | Aluminum |

| Tool Diameter | ø80 |

| Cutting Conditions |

|

Example

| Workpiece | Cyl-Head (Fitting face) |

|---|---|

| Material | Aluminum |

| Tool Diameter | ø234 |

| Cutting Conditions |

|

Product Specification

Tool Specification

| Process covered |

Cyl-Head (Fitting face) etc. |

|---|---|

| Material | Not specified (applicable to various materials) |

| Diameter | ø80 - |

| Standard conditions |

|