Tilt Type for both ends of the holePAT.P

Easily deburrs even complex hole shapes

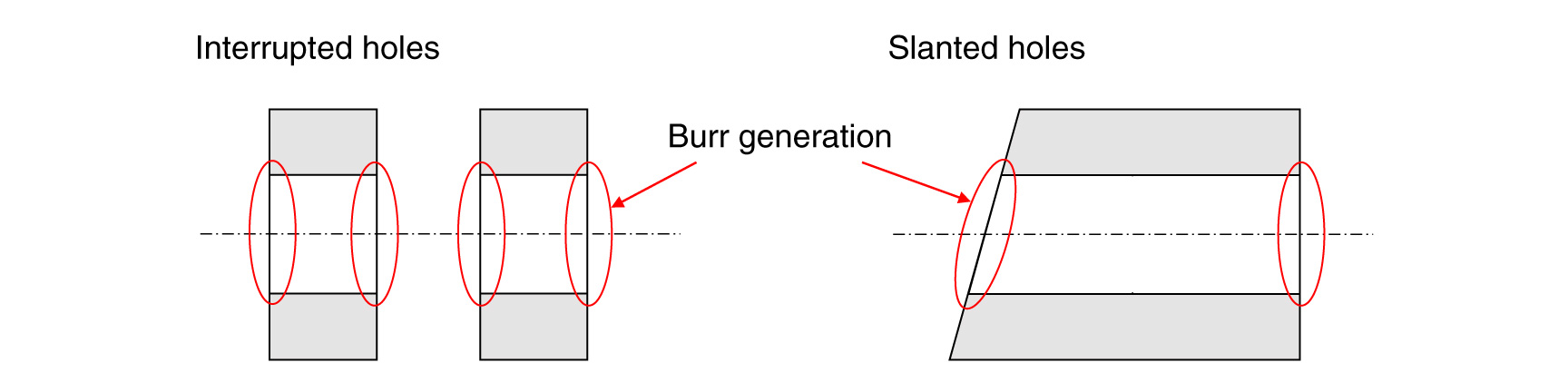

- Efficient deburring of intermittent holes, sloped

surfaces, and complexly shaped workpieces!

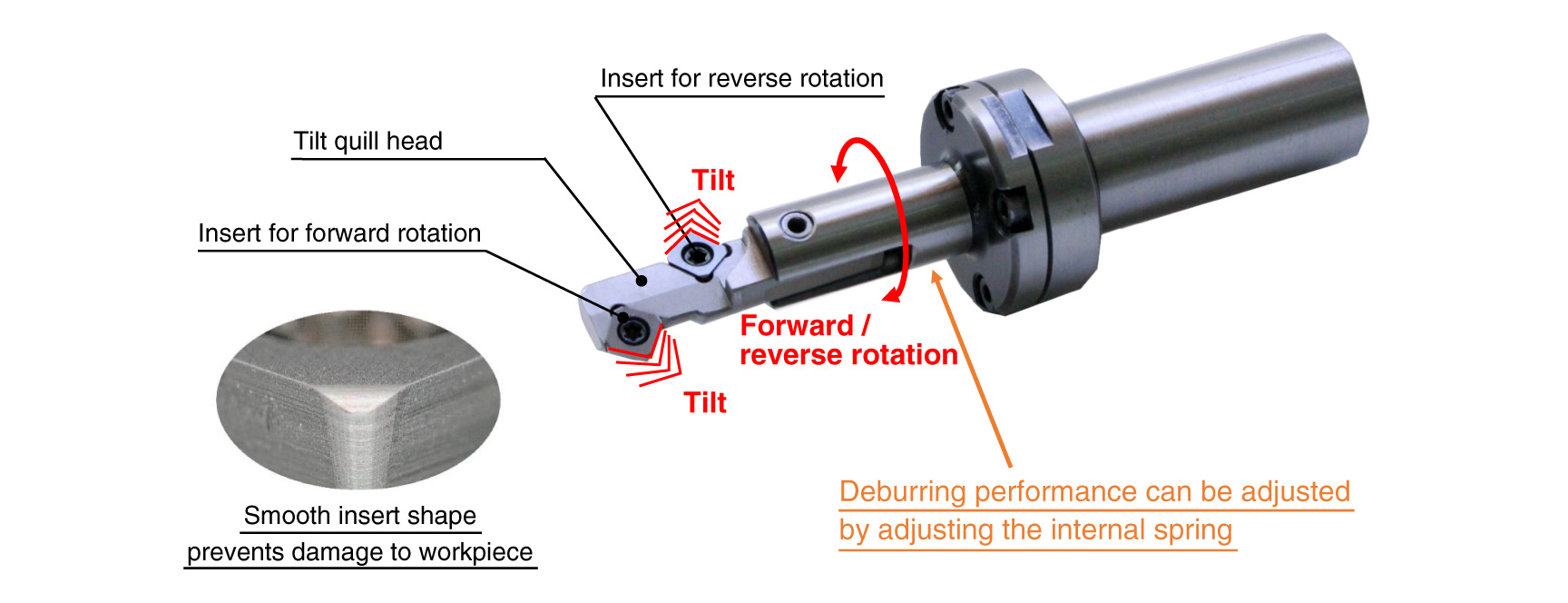

- Mechanical deburring achieved by tilt mechanism.

- No complicated toolpath programs required.

“Amazing Ideas / Facts!”

Tilt type deburring tool for both side of the hole enables deburring of various workpiece shapes such as interrupted holes, inclined surfaces, and complex shapes.

Adoption of a tilt mechanism eliminates the need for complicated tool path programs even for complex shapes, enabling stable deburring using a machining center, contributing to improved productivity.

POINT!

Structure of tilt type deburring holder for both side of the holeExcellent !

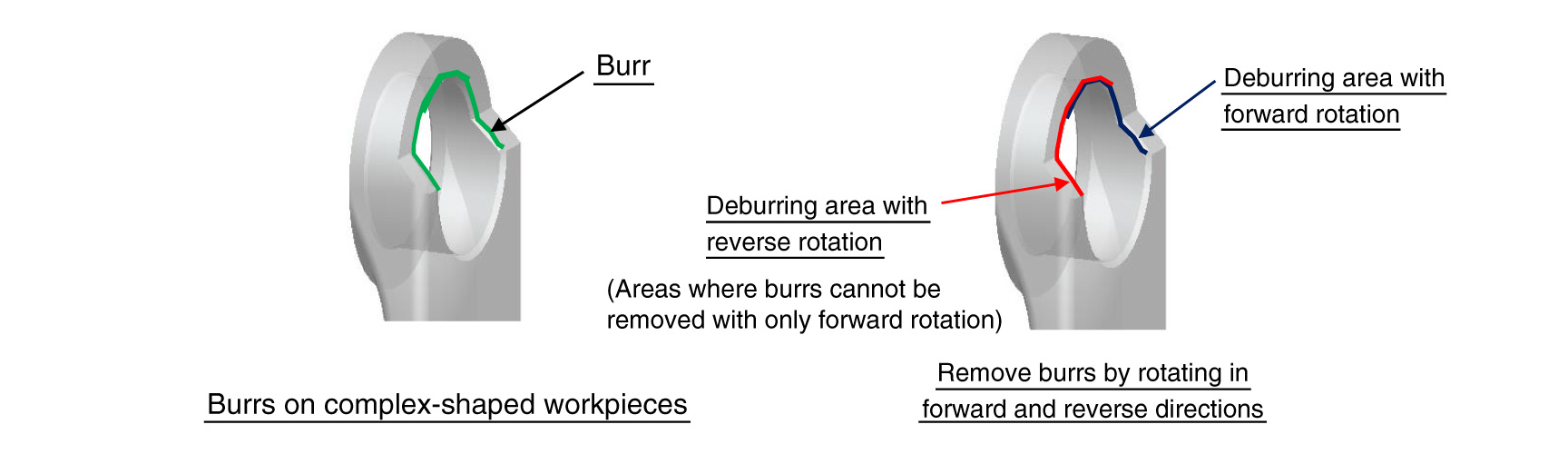

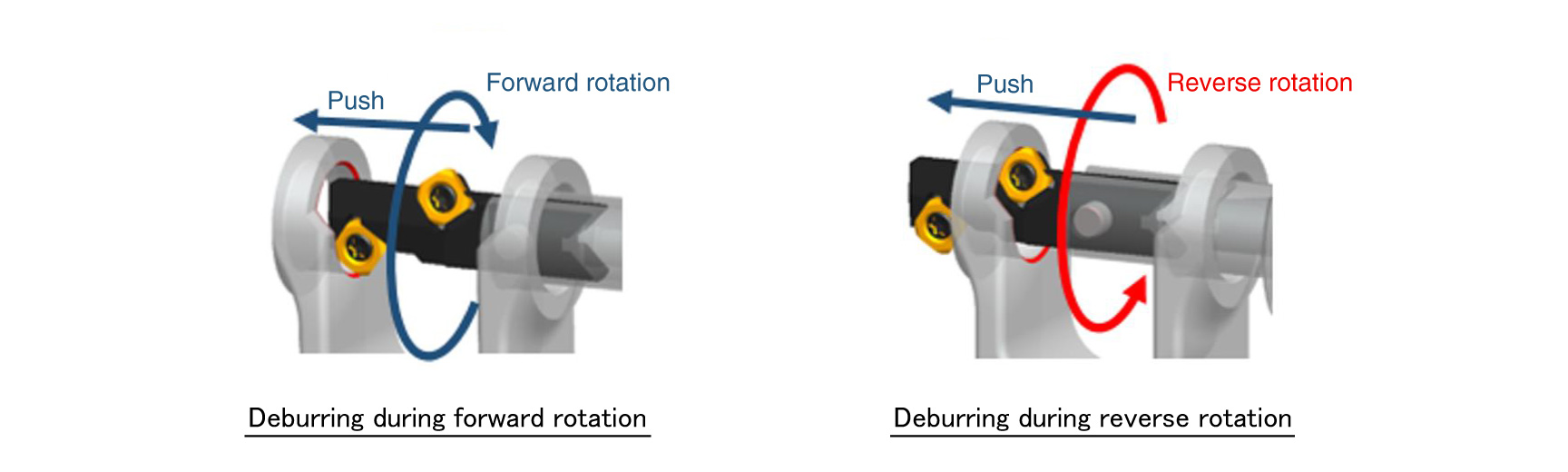

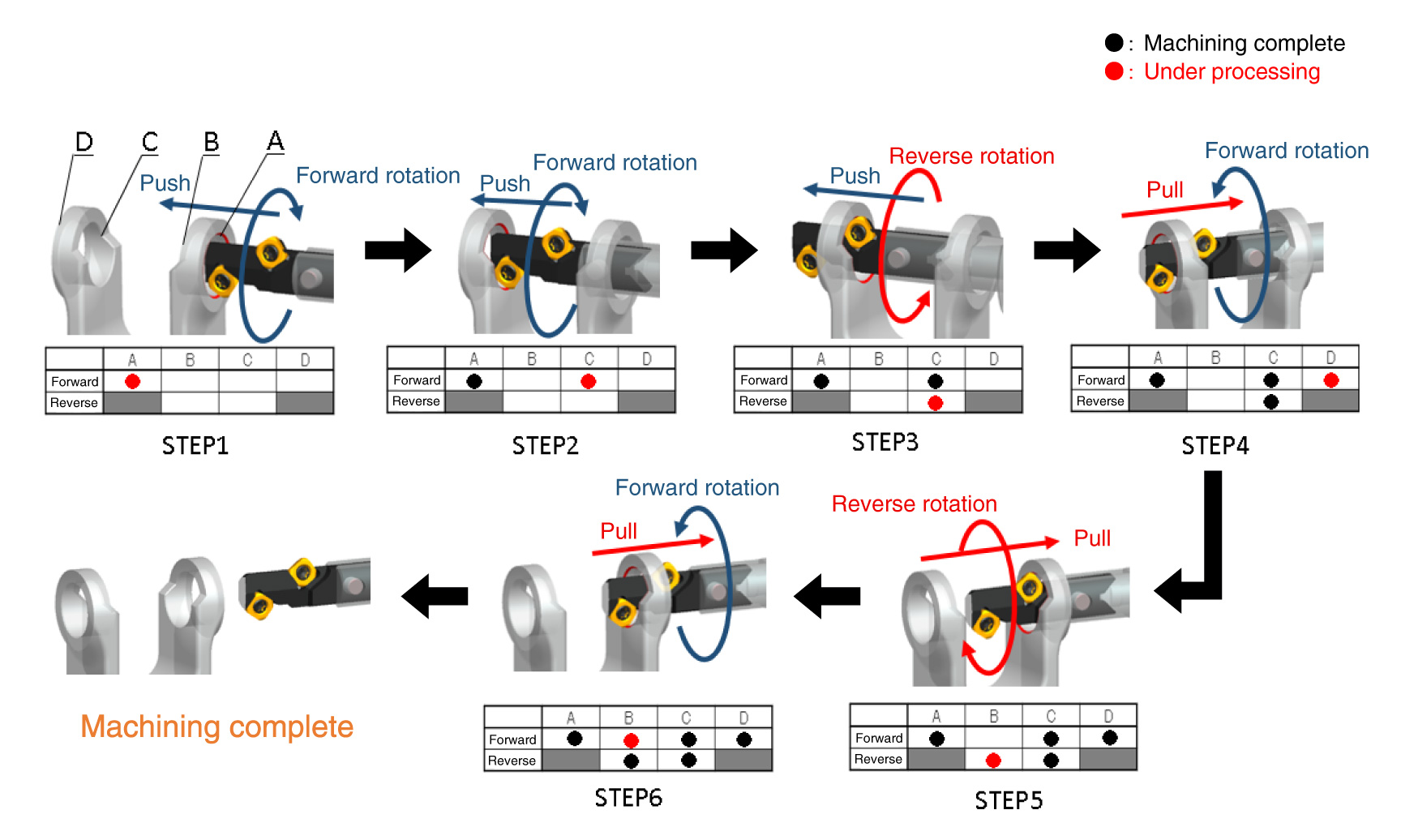

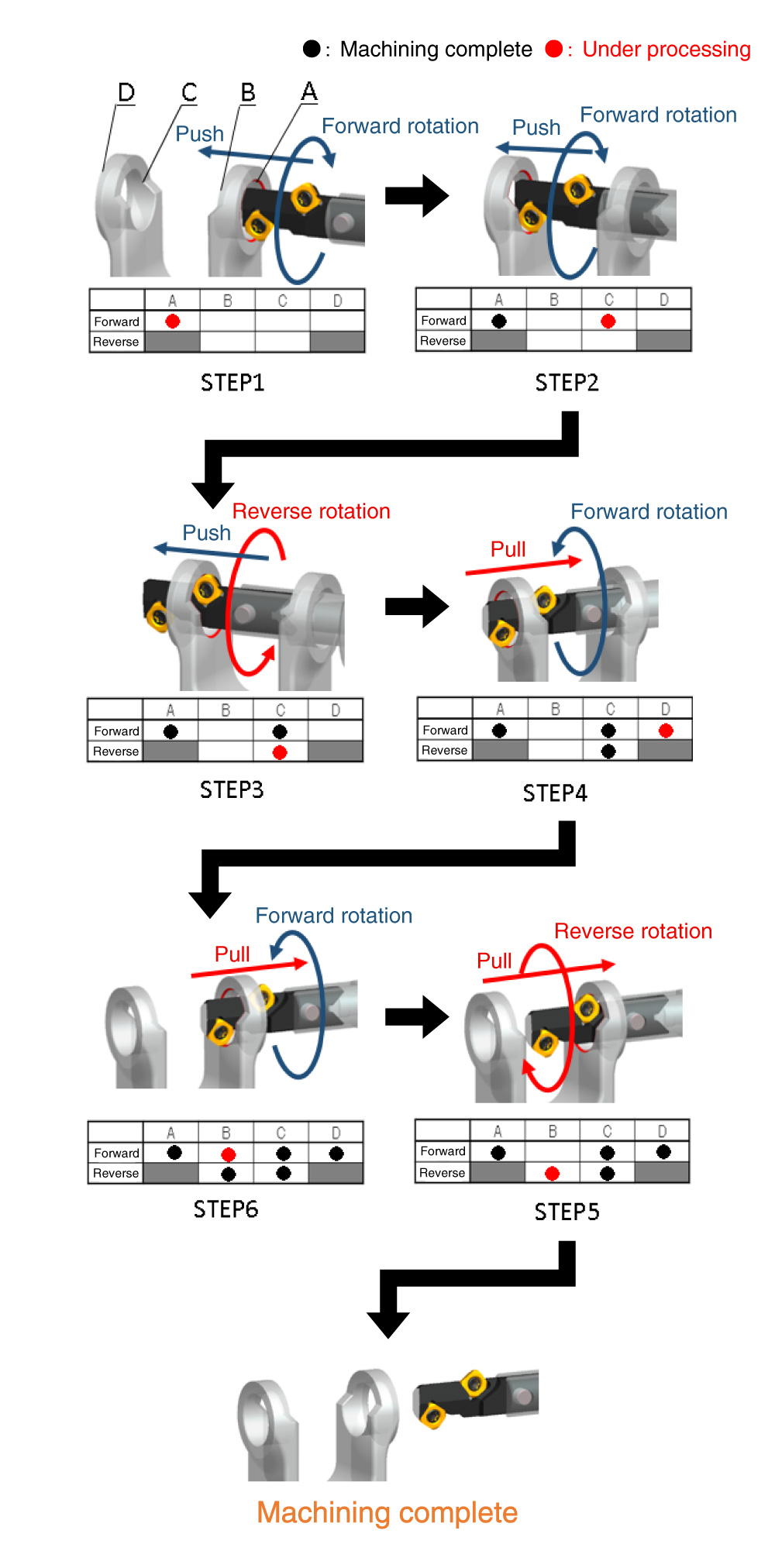

Example of deburring using forward and reverse rotation

Processing method

Background / Point for Development

Background

- Burrs on complex-shaped workpieces were generally removed manually.

- Manual work was inefficient and resulted in unstable deburring quality such as uncut / overcut patrs

Point for Development

- The tilt mechanism with multiple cutting edges in forward/reverse rotation enables stable deburring even with complex workpiece shapes, contributing to improved productivity through machining center processing.

Example

Deburring complex shapes using forward / reverse rotation (Work: Yoke parts)

Product Specification

Tool Specification

| Process covered |

Yoke (Deburring both sides of the hole), etc. |

|---|---|

| Material | Steel, Cast iron |

| Diameter | ø16 - |

| Standard conditions |

|

Applicable workpiece shape