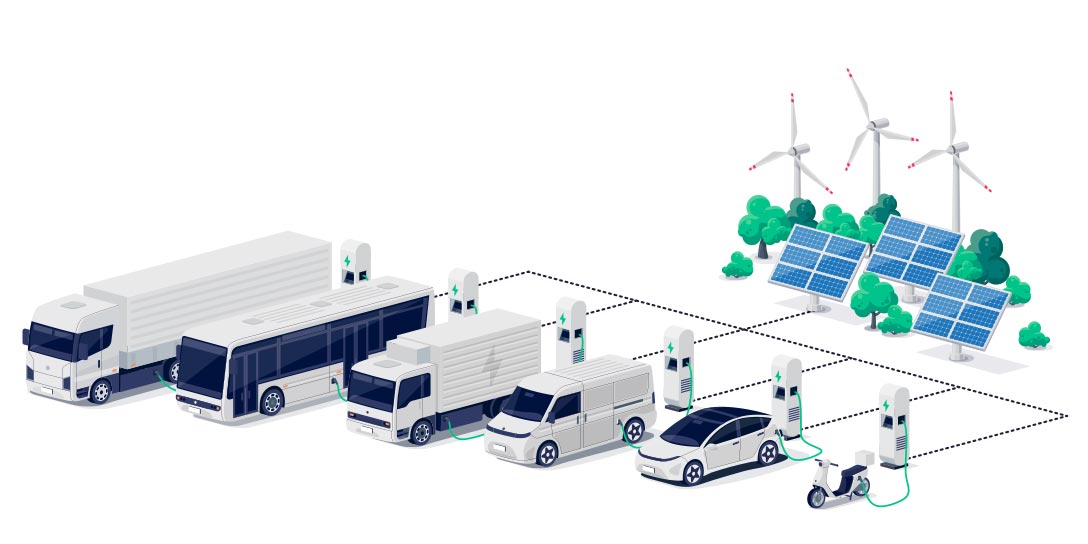

Our Initiatives for

Electric Vehicle

- Currently, the automotive industry is undergoing the biggest shift in its history.

- BEV, HEV, PHEV, FCEV etc.

FUJISEIKO will run together with

you towards the future of the electrified society

1. Battery Manufacturing

For better & faster cutting precision

With our partner's co-op, we can propose various technologies and demonstrative methods for battery manufacturing.

Rotary

Laser

Ultrasonic

Mold

Any requests are highly welcome from other than our “core” technologies and strengths: “HIGH ACCURACY”, “HIGH QUALITY”, “HIGH EFFICIENCY” in the automotive industry

2. Motor Manufacturing

Our Support for efficiency and improvement:

- Prototype Development

- Process Demonstration

- High Precision Machining

- Manufacturing Equipment

- Changeover

- Multi-type Production

- Dust Collection

- Transferring Jigs

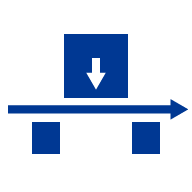

Case Study: Motor Stator Manufacturing Process

-

Coil forming

Peeling

(flat wire)- Peeling device

- punch

- Die

- work clamp

Chip disposal

- suction nozzle

- 3D printer

jig

- Image measurement jig

- 3D printer

-

Assembly

bending

- Special Bending jig

jig

- Coil fixing jig

-

Cutting

cutting

- Nippers for cutting winding wire

-

Welding

-

Powdering

Deburring

- Varnish shaving Bo

(inner diameter trimming)

cutting

- slot paper cutting tools

- Varnish shaving Bo

-

Inspection/

Shipping