Honing Head

Total support from processing

to maintenance

- High-precision expansion structure for super-finishing of bore diameters

- Wide variety of honing heads available

- Custom-made to meet machine specifications.

- A wide range of services including truing, dressing, repairing, etc.

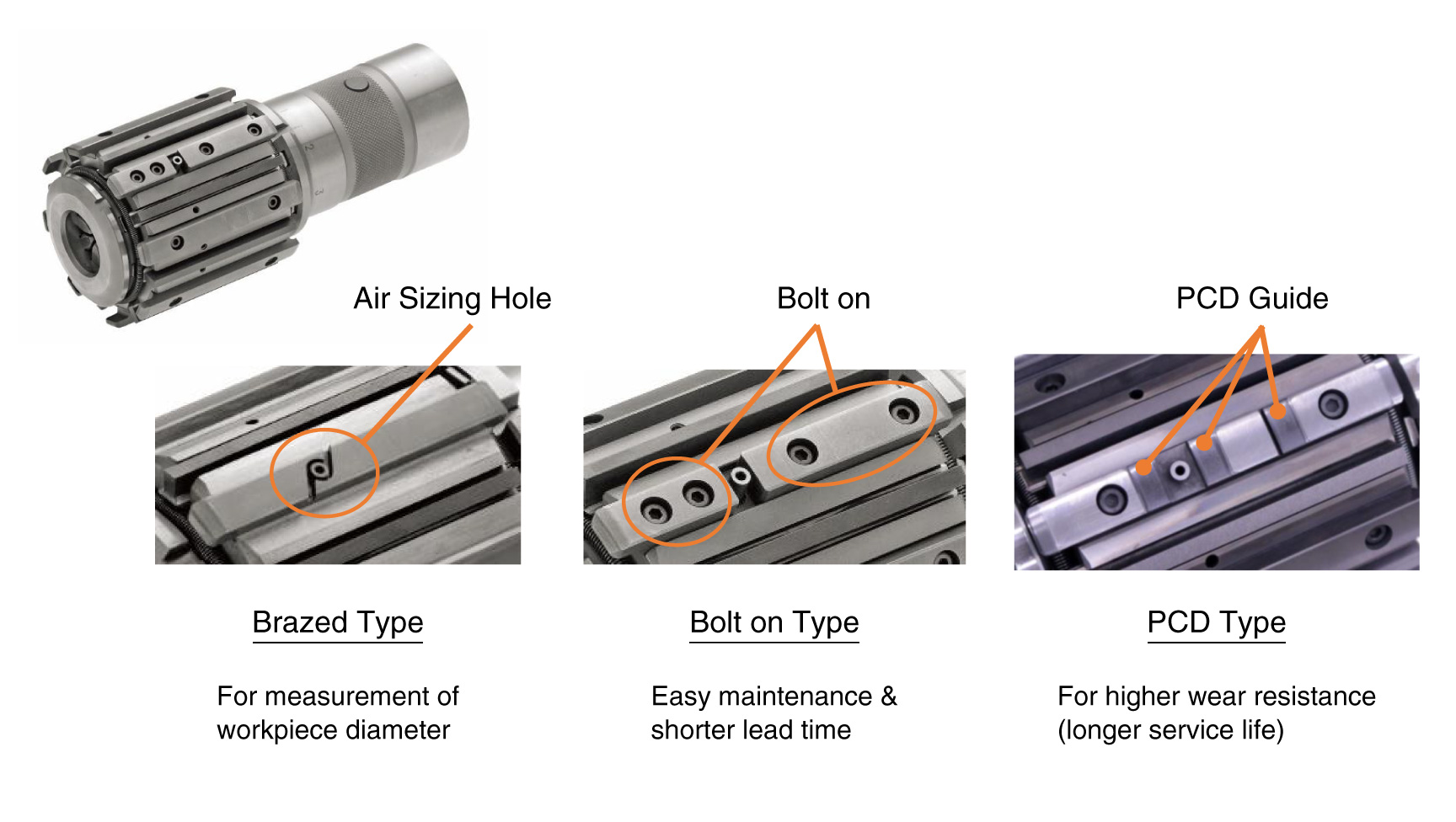

- Air Sizing (additional option)

“Amazing Ideas / Facts!”

High precision, high quality honing heads, compatible with various honing machines.

A wide range of maintenance services also available!

- Honing stone replacement, truing / dressing

- Guide pad (carbide) replacement

- Replacement of any other consumable parts

POINT!

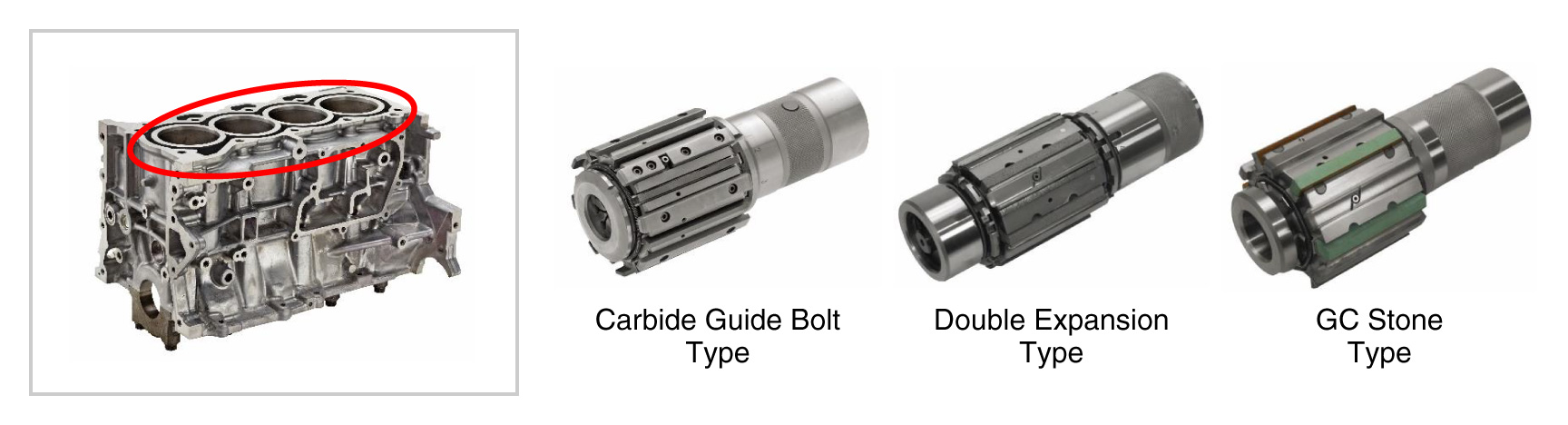

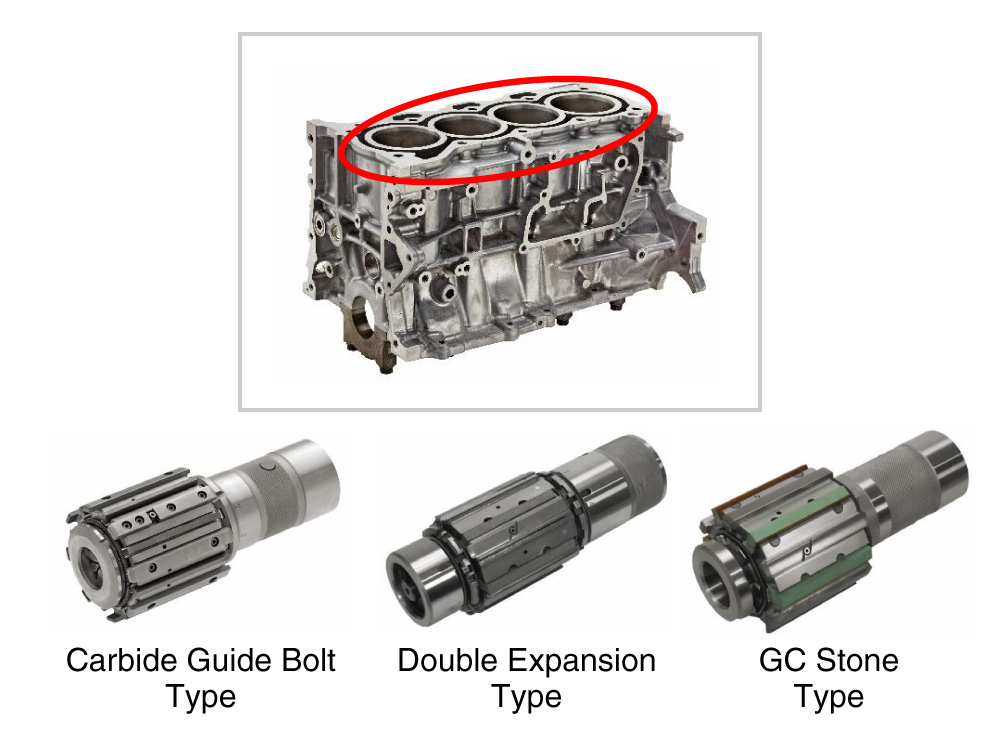

Various honing heads can be manufacturedExcellent !

Cylinder Block / For Bore Holes

Connecting Rod / For Large End Hole

Gear / For Shaft Hole

POINT!

Carbide guide pads can be proposed according to the applicationExcellent !

POINT!

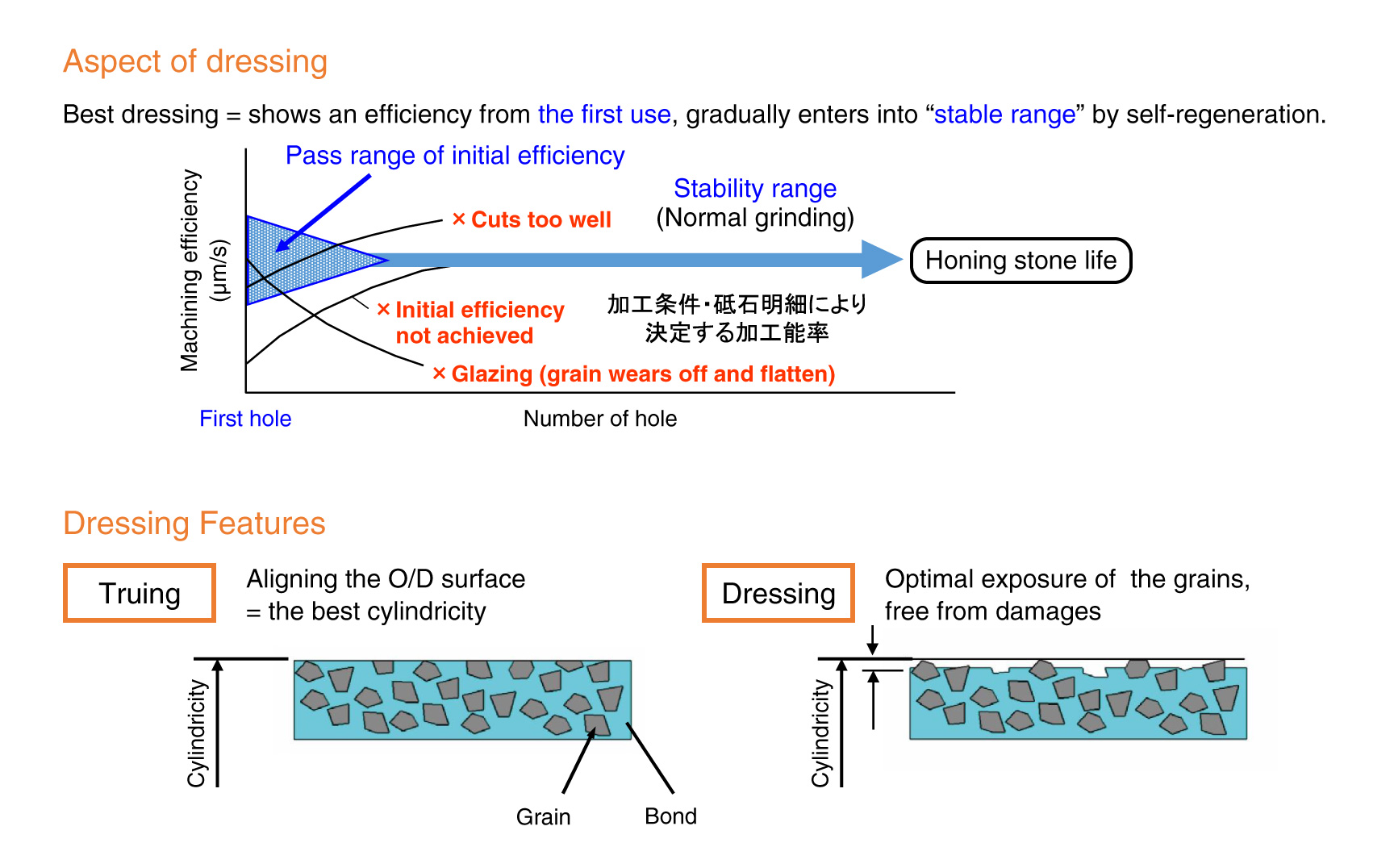

Truing and Dressing of honing stone using cylindrical grinderExcellent !

Instead of manual dressing by experience, Automation ensures the accuracy of dressed wheel surface, realizes to keep the stable quality (quantifiable dressing)

Background / Point for Development

Background

- Honing Heads were mainly made overseas, which required long lead times and were expensive.

- The maintenance required complicated/time-consuming process, involving body repairing, stone peeling/truing/dressing all by different manufactures.

Point for Development

- Domestic production by our superior and more reliable technology : the craftsmanship as a special tool manufacturer.

- The truing/dressing are now processed with our unique method, always ensuring the stable quality.

Simplified process for maintenance by one, fully responsible manufacturer has significantly improved the lead time and the cost performance.