G7 Drill series

Carbide drill series for

one-shot machining with

IT7 accuracy!

- Outstanding finishing accuracy produced by “drilling edge” + “special reaming edge”!

- Hole finish in one shot (IT7)

- Line-up for “w/o preholes”, “Casted holes” and “High feeds”

WHAT IS G7 Drill series?

① G7X Drill

For w/o preholes

High-precision machining

- Drilling edges: 2/ Reaming edges: 2

- Accuracy: IT7

- Surface roughness: ≤ 6.3z

- Cylindricity: ≤ 8µm

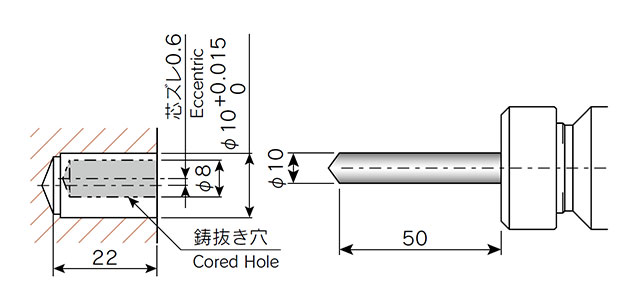

② G7T DrillPAT.

For casted holes

Stable machining even with casted holes

- Drilling edges: 3/ Reaming edges: 3

- Accuracy: IT7

- Surface roughness: ≤ 6.3z

- Cylindricity: ≤ 8µm

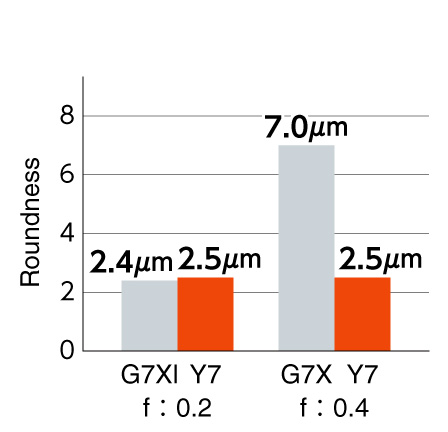

③ Y7 Drill

For high feed

High feed version of G7X with twisted flute

![]()

- Drilling edges: 2/ Reaming edges: 4

- Accuracy: IT7

- Surface roughness: ≤ 6.3z

- Cylindricity: ≤ 8µm

“Amazing Ideas / Facts!”

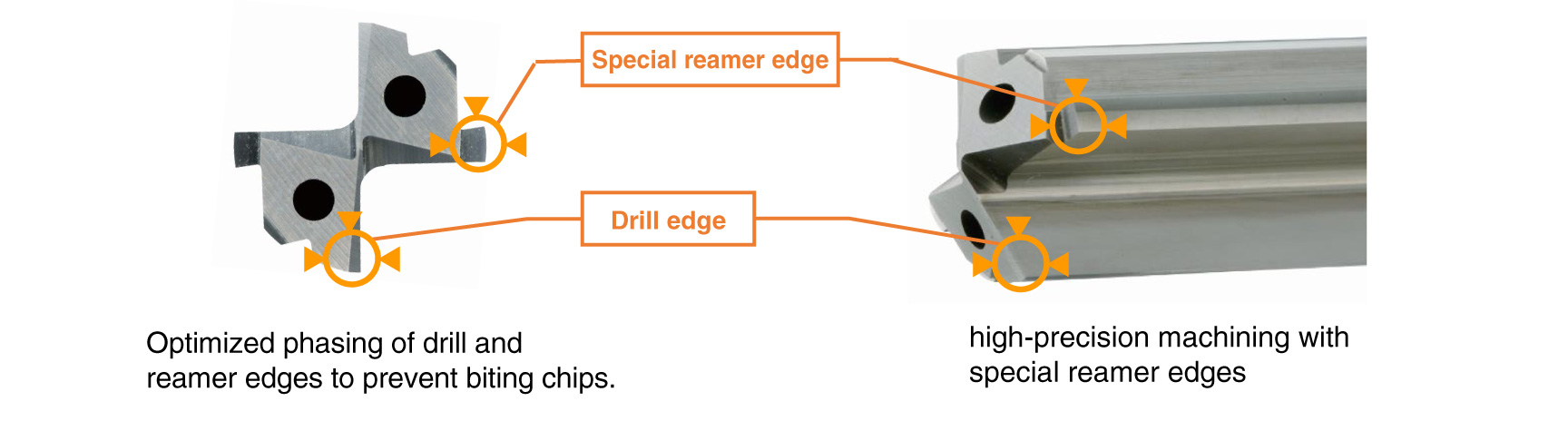

The G7 drill series consists of drilling edges and special reaming edges.

By separating each flute, chips from the cutting edge are discharged separately to eliminate chip entrapment, while the reaming edge uses a special cutting edge profile to realise one-shot drilling in IT7-grade holes.

The line-up includes the G7X drill for w/o preholes, the G7T drill for casted holes and the Y7 drill as a high feed version of the G7 drill.

G7X Drill(w/o preholes)

IT-7 grade hole accuracyGood !

G7T Drill(Casted holes)

IT-7 grade hole accuracyGood !

Y7 Drill

High-feed and high-precision machiningGood !

POINT!

The role of the cutting edge, separated by its functionExcellent !

Background / Point for Development

Background

- With the shift from specialised machines to general-purpose machines, the need for drill-reamer that combines drill and reamer in one tool has increased in order to reduce cycle times.

- However, chip entrapment and inconsistent machining accuracy continued as a problem.

Point for Development

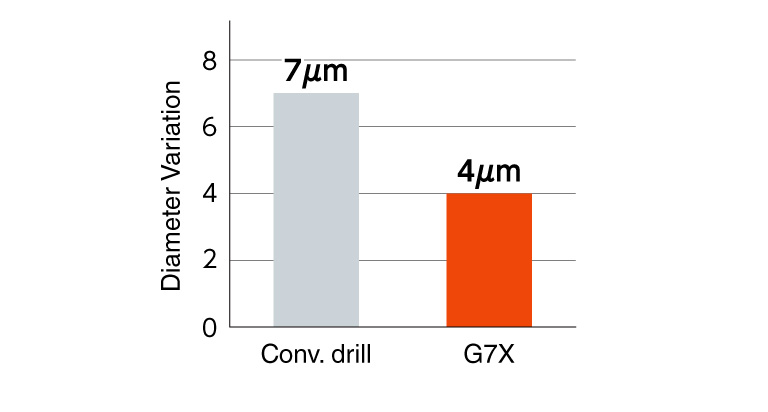

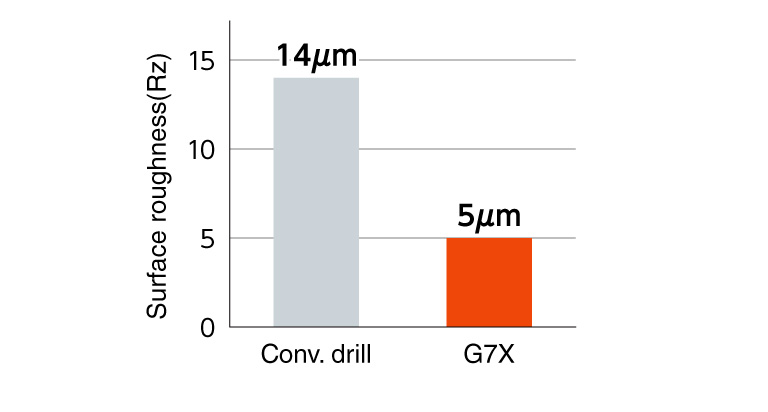

- By optimizing the phase of drill edges and reamer edges, the tool results in better chip evacuation.

- Using special profiles for reamer edges, the tool improves the machining accuracy to IT7.

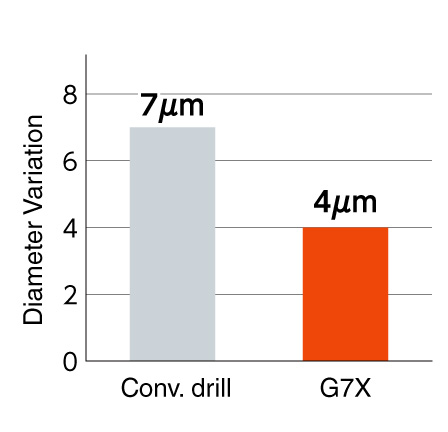

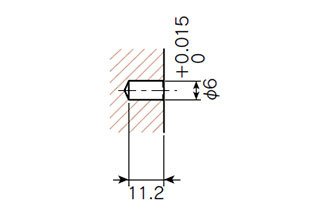

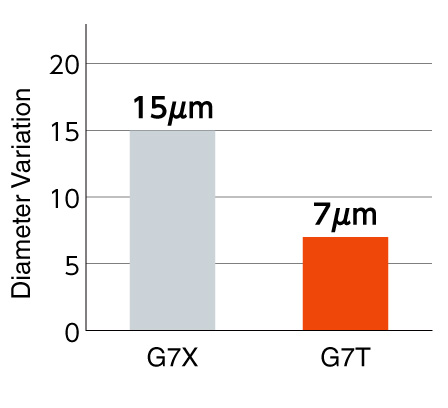

Examplew/o preholes

| Tool | G7X drill |

|---|---|

| Workpiece | Aluminum block |

| Material | ADC12 |

| Tool Diameter | ø6mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

Hole Diameter

Surface Roughness

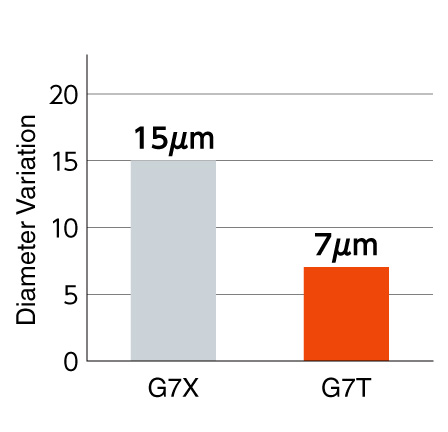

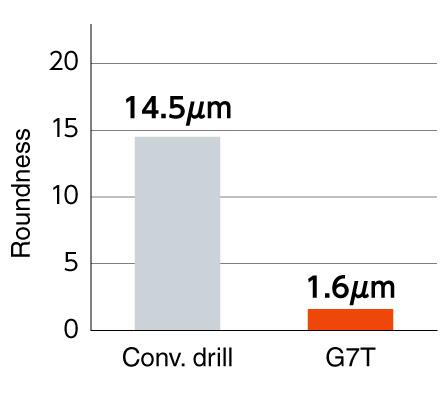

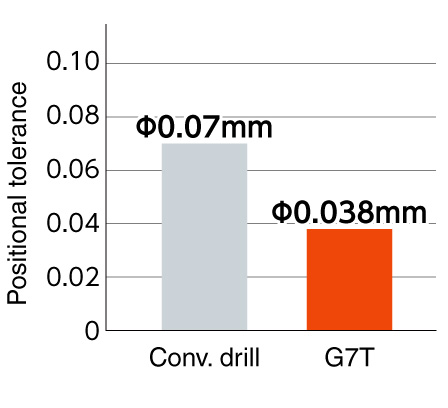

ExampleCasted holes

| Tool | G7T drill |

|---|---|

| Workpiece | Aluminum block |

| Material | ADC12 |

| Tool Diameter | ø10mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

Hole Diameter

Roundness

Positional Tolerance

Product Specification

G7X Drill

Tool Specification

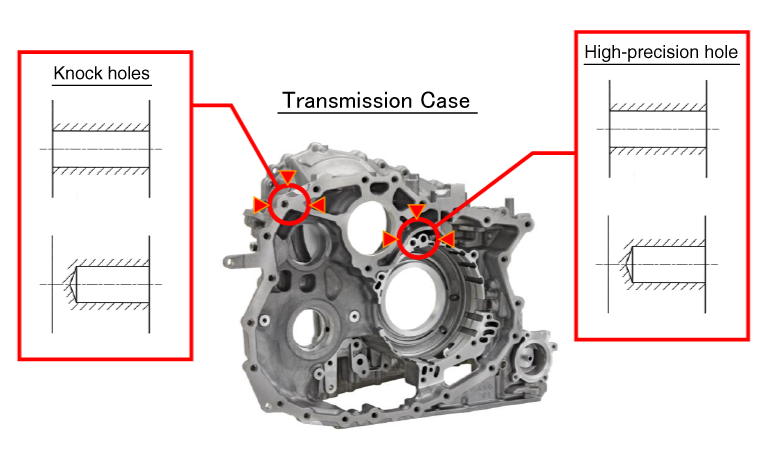

| Process covered | knock holes Aluminum high-precision holes / w/o preholes *One-shot from raw material |

|---|---|

| Diameter | ø5 - |

| Standard conditions |

|

| Performance | IT7 |

G7T Drill

Tool Specification

| Process covered | knock holes Aluminum high-precision holes / casted holes *One-shot from raw material |

|---|---|

| Diameter | ø5 - |

| Standard conditions |

|

| Performance | IT7 |

Y7 Drill

Tool Specification

| Process covered | knock holes Aluminum high-precision holes / w/o preholes *One-shot from raw material |

|---|---|

| Diameter | ø6 - |

| Standard conditions |

|

| Performance | IT7 |

Example of applicable work