GHI Reamer Series

Excellent finishing accuracy

Carbide reamer series

for cast iron and steel

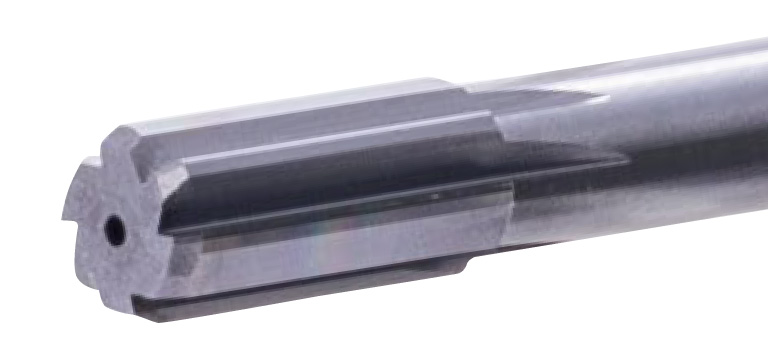

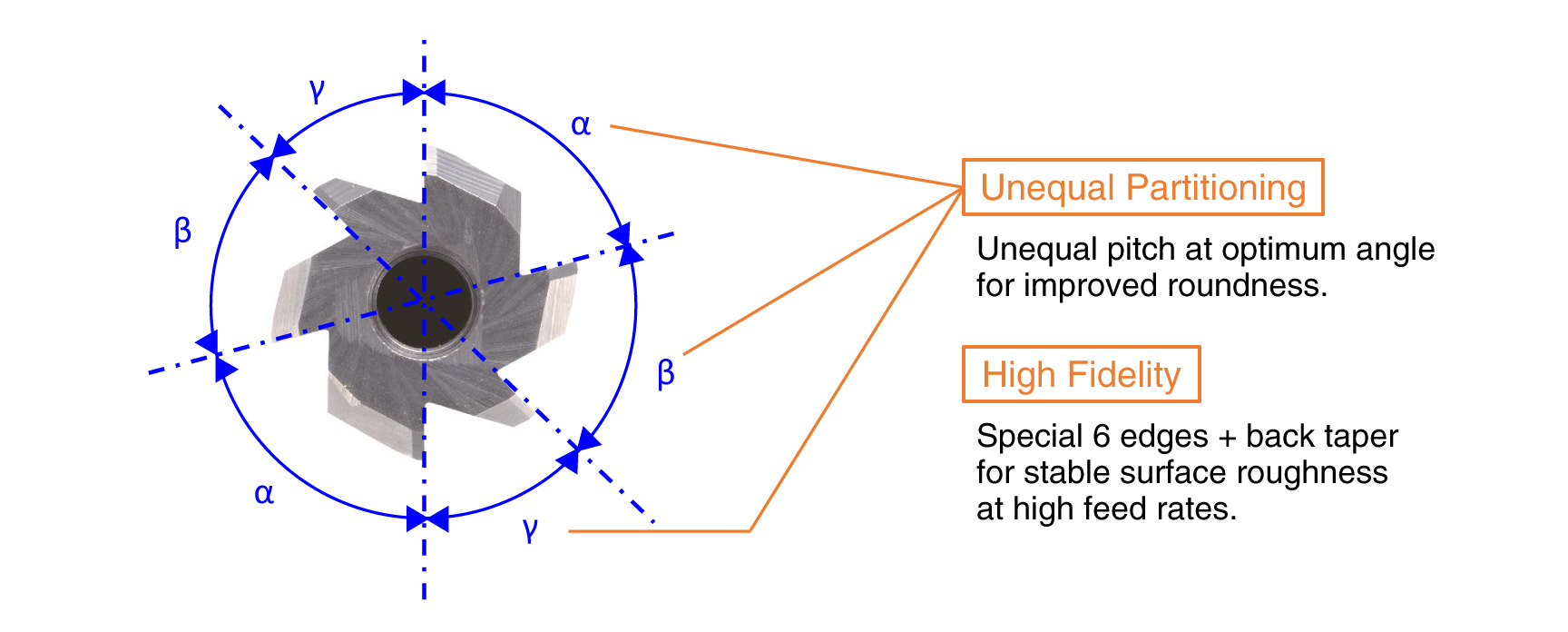

- Unequal spacing 6 edges for high-precision,

high-efficiency machining

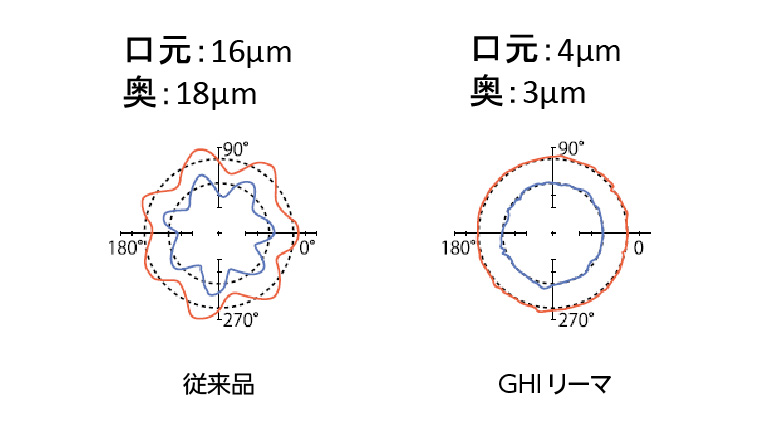

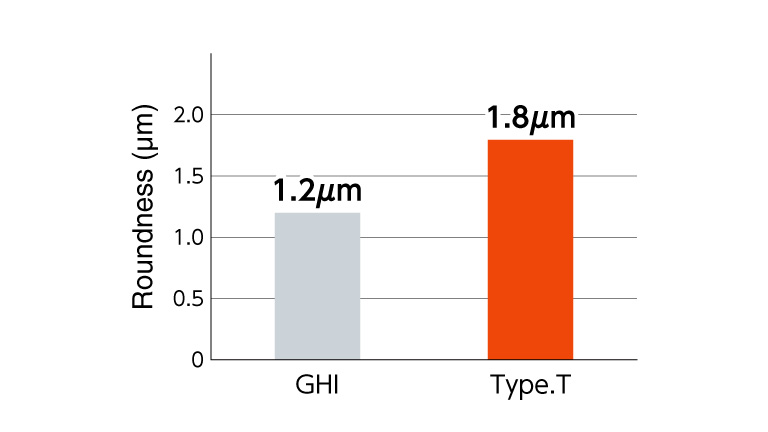

- Excellent roundness by optimum unequal spacing

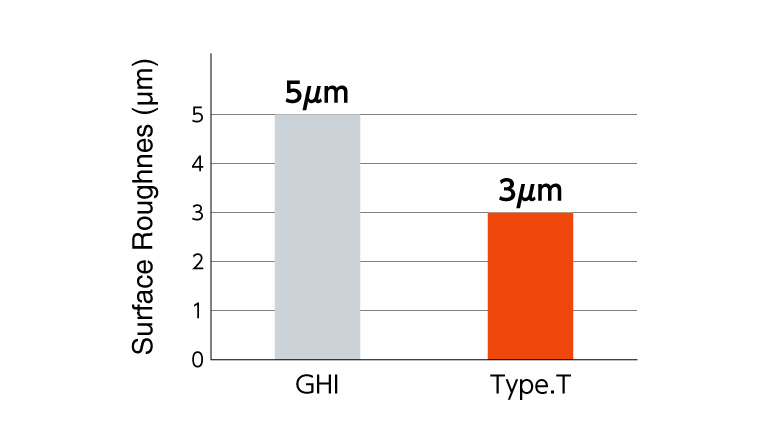

- Excellent surface roughness by 6 edges

- Highly efficient machining with high feed rate

WHAT IS GHI Reamer series?

①GHI Reamer

For general finishing

Feature: 6 Edges with unequal division

High-precision machining

- Accuracy: IT7

- Roundness: ≤ 10µm

- Surface roughness: ≤ 12.5z

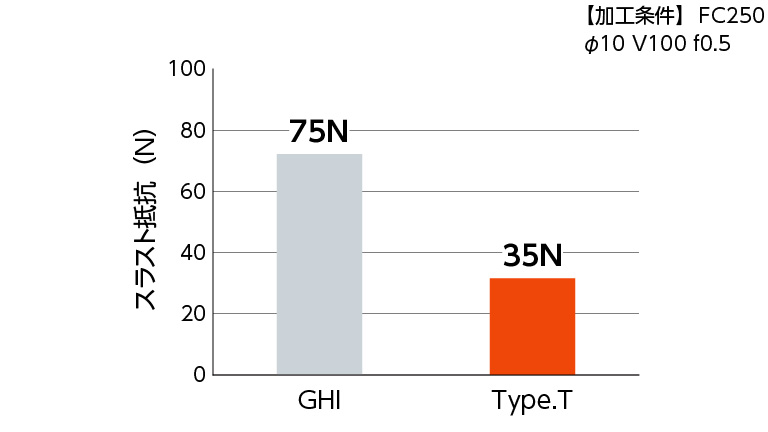

②GHI Reamer Type.T

For thin-walled workpieces

Feature: Low-resistance machining with right-hand twisting

- Accuracy: IT7

- Roundness: ≤ 10µm

- Surface roughness: ≤ 12.5z

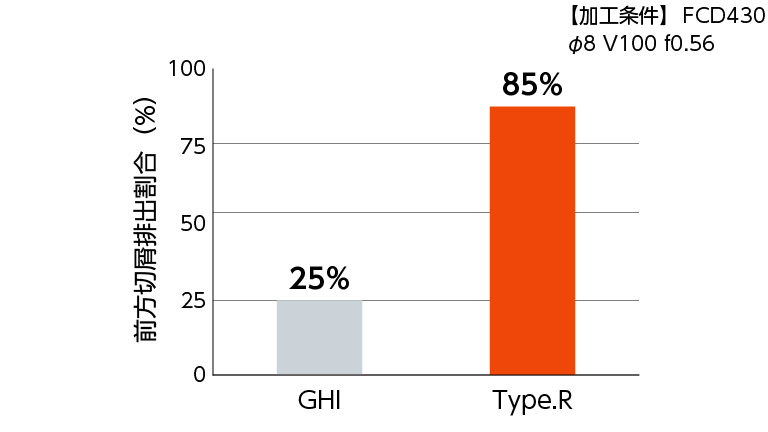

③GHI Reamer Type.R

For through-hole

Feature: Improved through-hole chip evacuation with left-hand twisting

- Accuracy: IT7

- Roundness: ≤ 10µm

- Surface roughness: ≤ 12.5z

“Amazing Ideas / Facts!”

The GHI Series Reamers for cast iron and steel:

- Excellent roundness and surface roughness due to the optimized unequal spacing 6 cutting edges.

- Highly efficient machining at high feed rates contributes to shorter cycle times.

- Type T for thin-wall and Type R for through-hole are also available.

Outstanding roundnessGood !

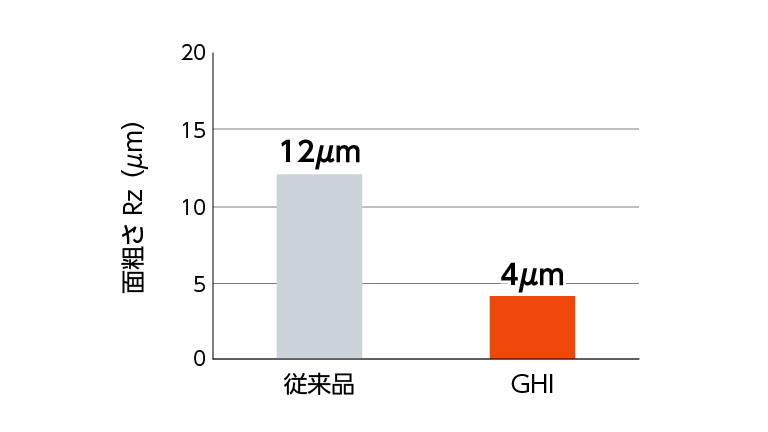

Excellent surface roughnessGood !

Type.T (right-hand twisting)

Reduced cutting resistance (thrust)Good !

Type.R (left-hand twisting)

Improved chip evacuationGood !

POINT!

Machining accuracy by the 6 unequally cpaced edges, the optimal edge profile and the coating.Excellent !

Background / Point for Development

Background

- High feed operation with conventional multi-flute reamers often results in bad roundness and roughness.

Point for Development

- The optimized unequal spacing 6 cutting edges significantly improves roundness.

- The back taper suitable for high feed machining improves surface finish.

- The multi-layer coating contributes to lower tooling costs by extending tool life.

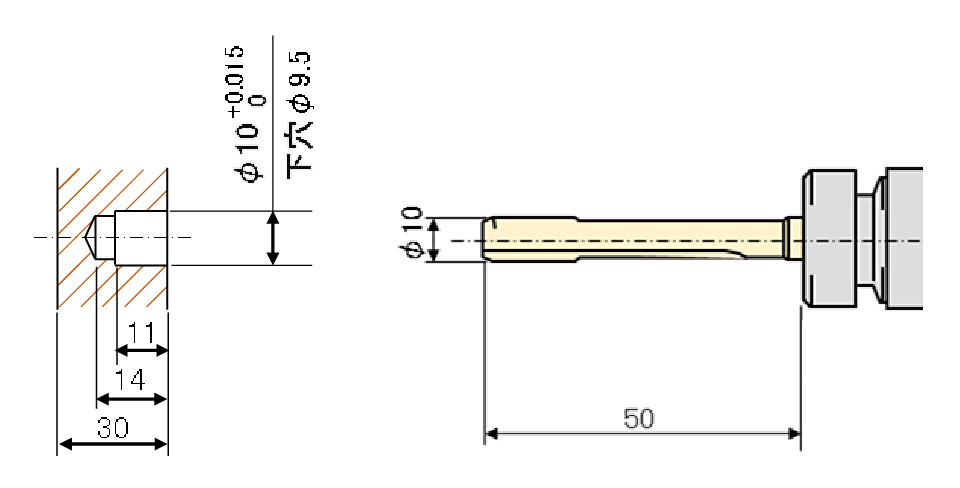

Example

| Tool | GHI reamer GHI reamer Type.T GHI reamer Type.R |

|---|---|

| Workpiece | Test piece |

| Material | FC250 |

| Tool Diameter | ø10mm |

| Cutting Conditions |

|

| Portion | ø0.2 |

| Required accuracy |

|

|---|

Roundness

Surface Roughness

Product Specification

GHI reamer

Tool Specification

| Process covered | FC/FCD/steel hole |

|---|---|

| Diameter | ø6 - |

| Standard conditions |

|

| Performance | IT7 |

GHI reamer Type.T

Tool Specification

| Process covered | FC/FCD/steel hole |

|---|---|

| Diameter | ø6 - 20 |

| Standard conditions |

|

| Performance | IT7 |

GHI reamer Type.R

Tool Specification

| Process covered | FC/FCD/steel hole |

|---|---|

| Diameter | ø6 - 20 |

| Standard conditions |

|

| Performance | IT7 |

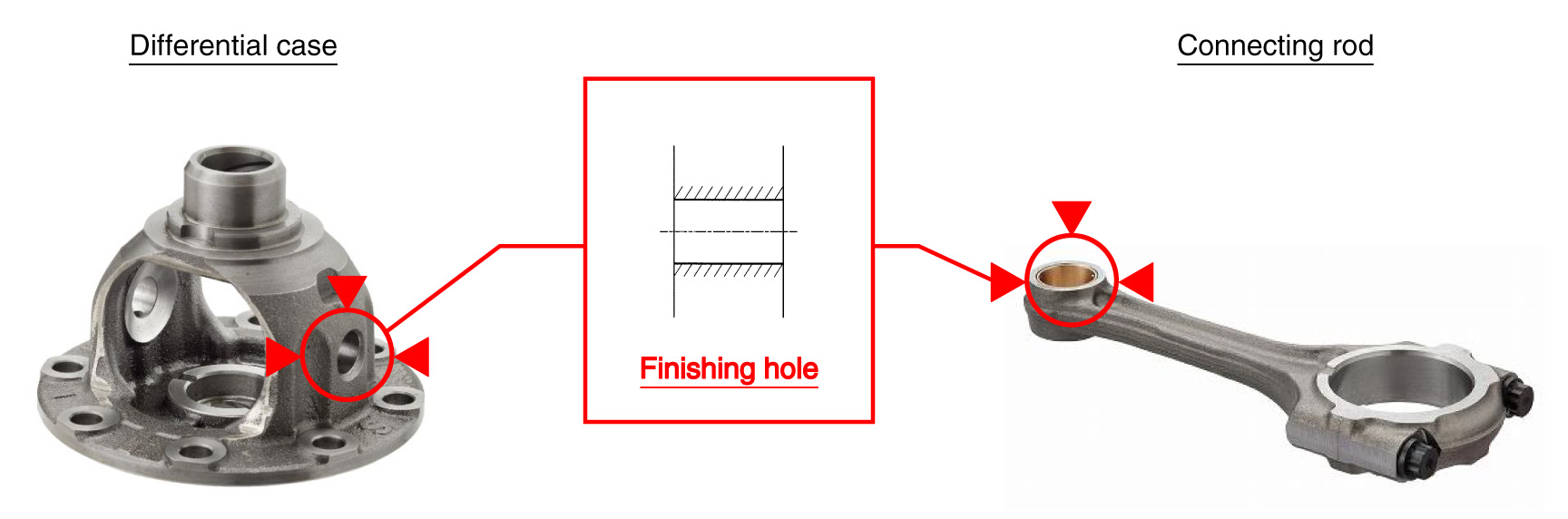

Example of applicable work