GK Drill series

Carbide straight flute drill

for general hole machining!

- Available in special shapes, tool specifications

matching to the needs of applications.

- Applicable in multi-steps & multi-grooves specifications

- Stable straightness achieved with double margins & straight flutes

- Available with DLC coating

WHAT IS GK Drill series?

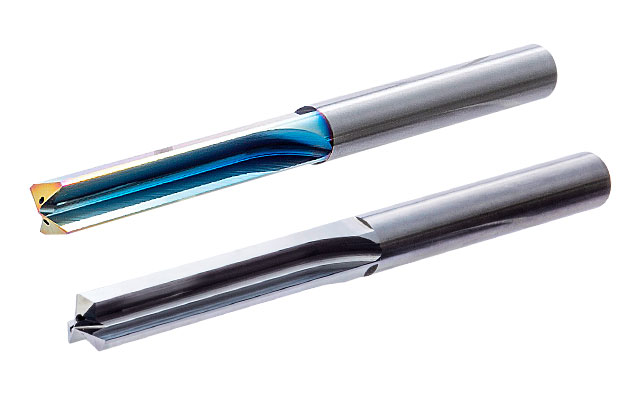

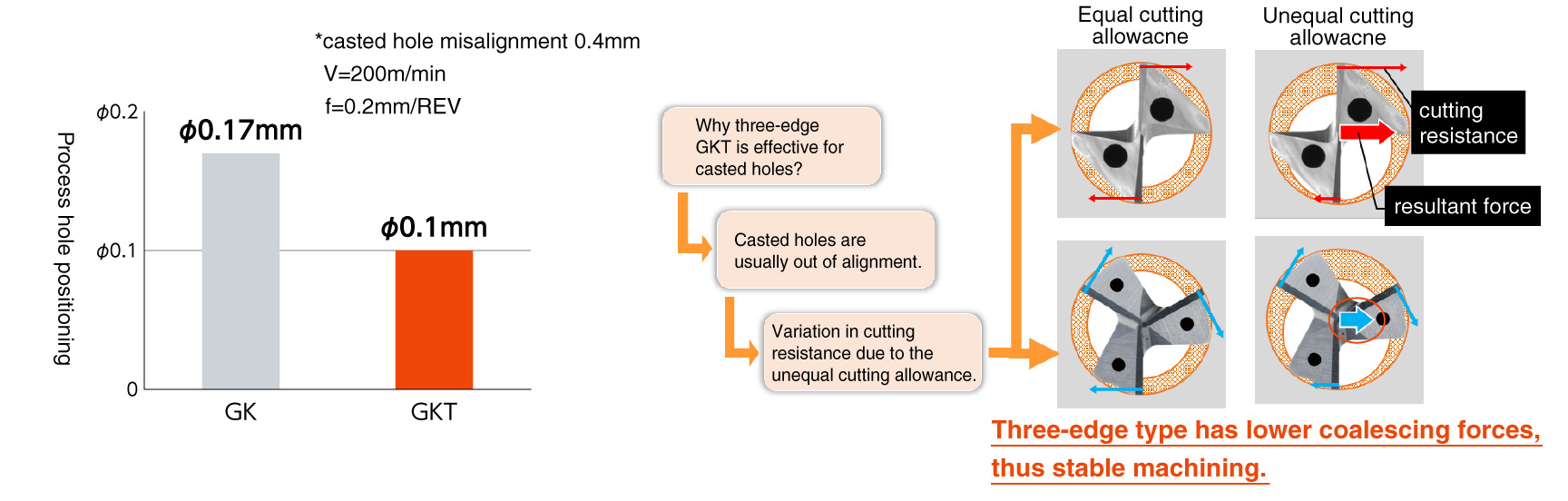

① GK Drill

For w/o preholes

Features: Stable machining with double margin & straight flute

- Carbide edge: 2

- Hole dia. accuracy: IT9

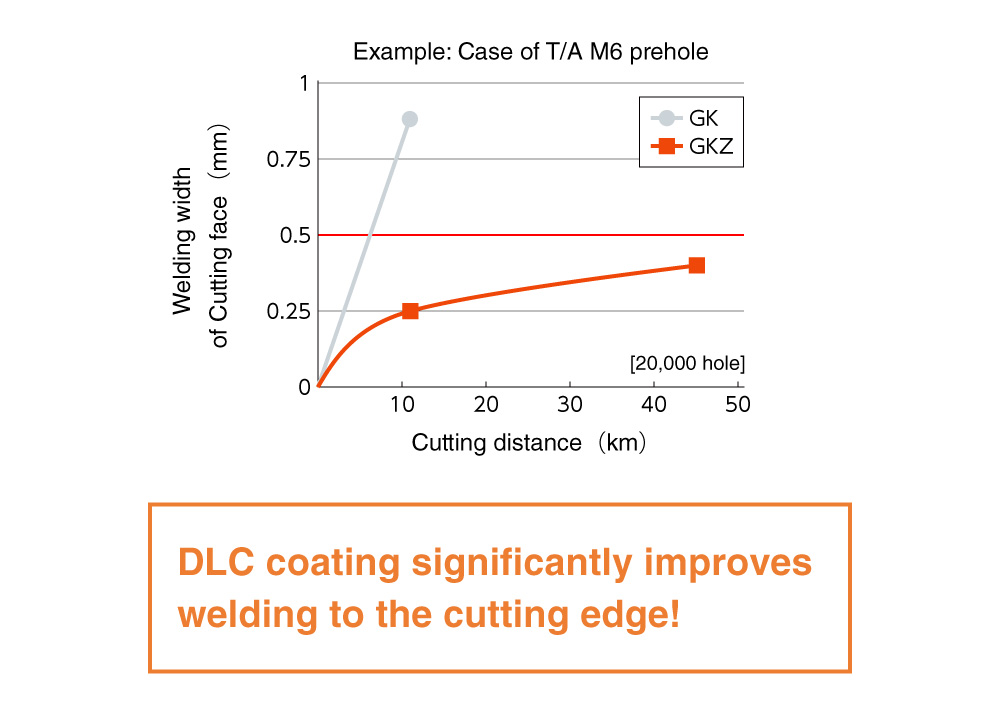

② GKZ Drill

DLC coating

Features: Improved aluminum welding Resistance version

- Carbide edge: 2

- Hole dia. accuracy: IT9

③ GKT Drill

For Casted holes

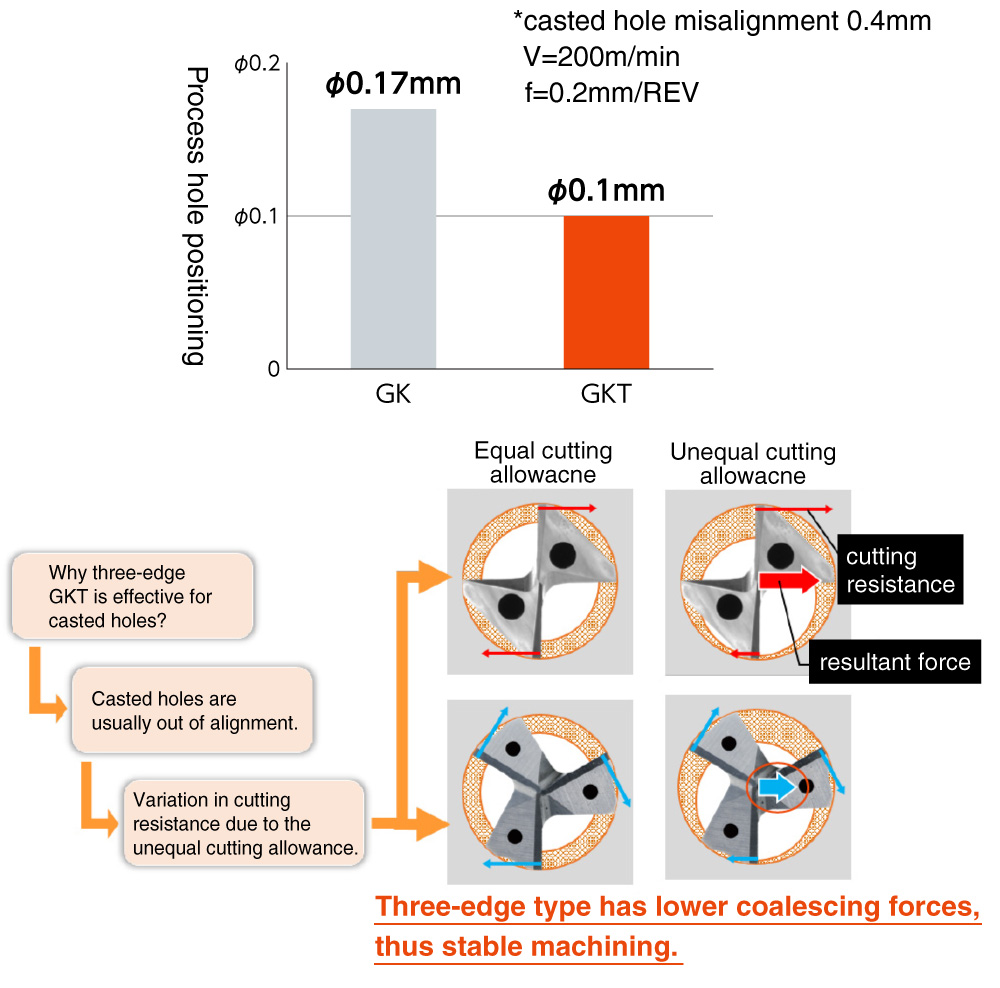

Features: Excellent hole positioning accuracy for casted holes

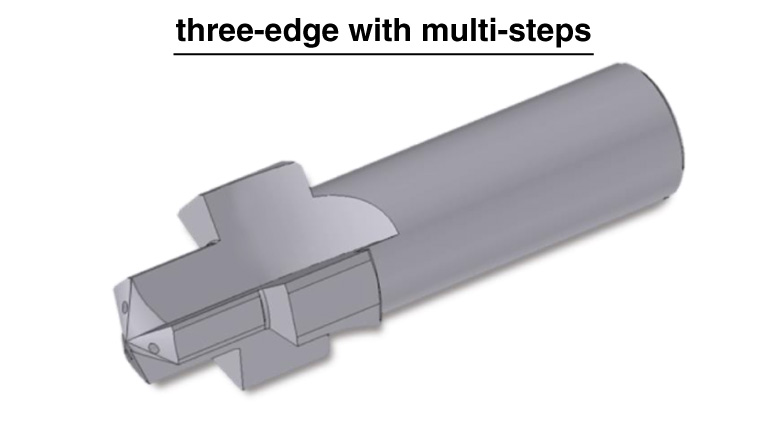

- Carbide edge: 3

- Hole dia. accuracy: IT9

“Amazing Ideas / Facts!”

The GK drill series is for general hole drilling with aluminium materials.

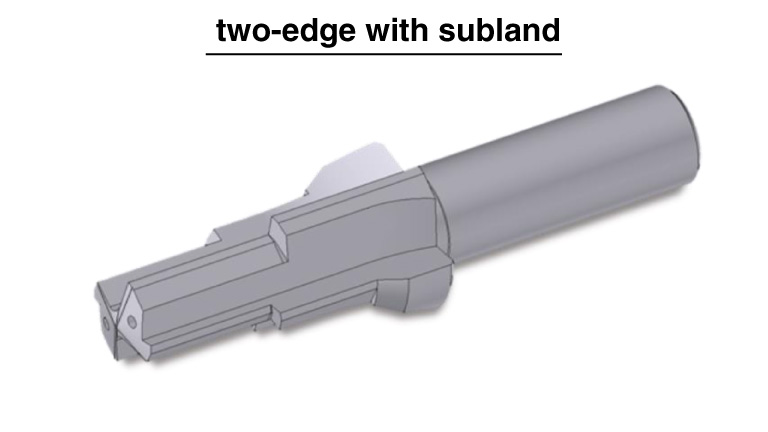

Special shapes such as multi-steps and multi-grooves can be available with a wide variety.

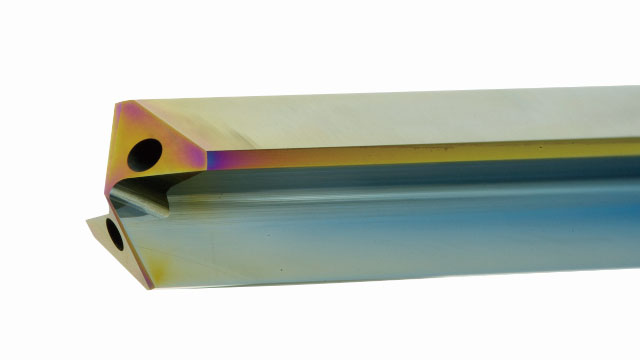

Stable accuracy in drilling hole is ensured by the double margin and straight flute.

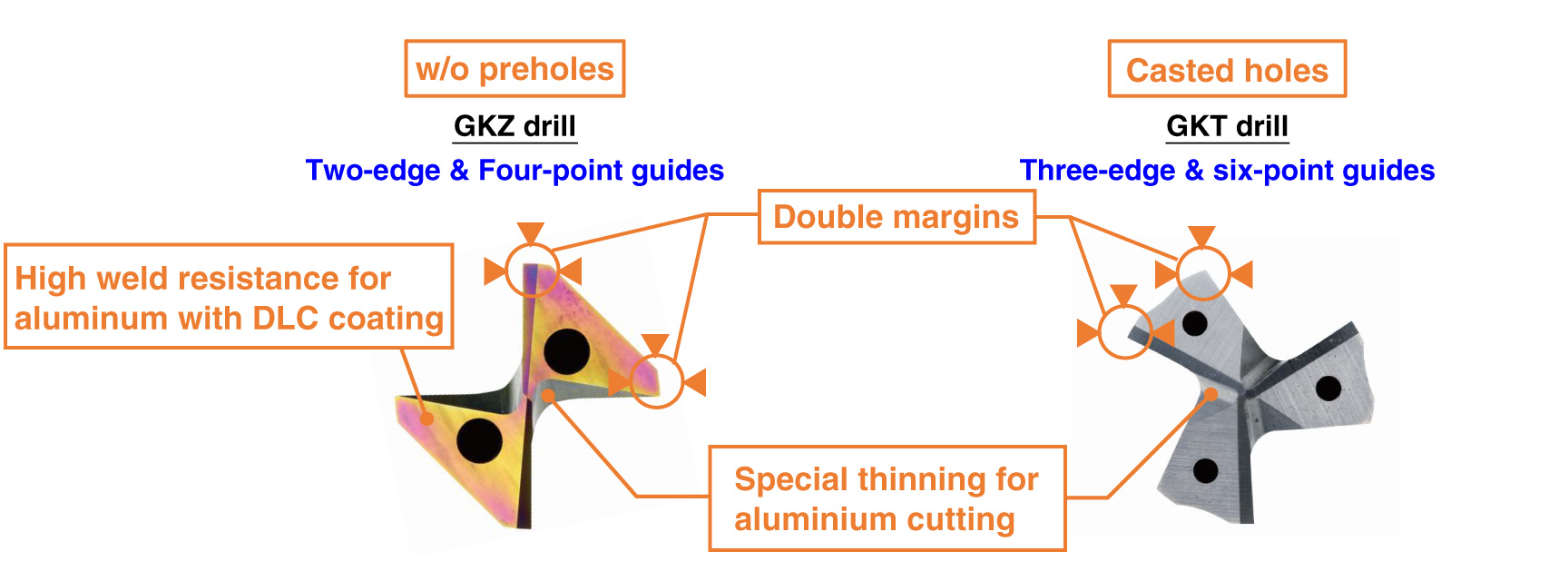

In addition, the three-edged type achieves excellent hole positioning for casted holes.

The line-up includes GK drill for w/o preholes, GKT drill for casted holes and GKZ drill with DLC coating for high welding resistance.

High degree of flexibility in design

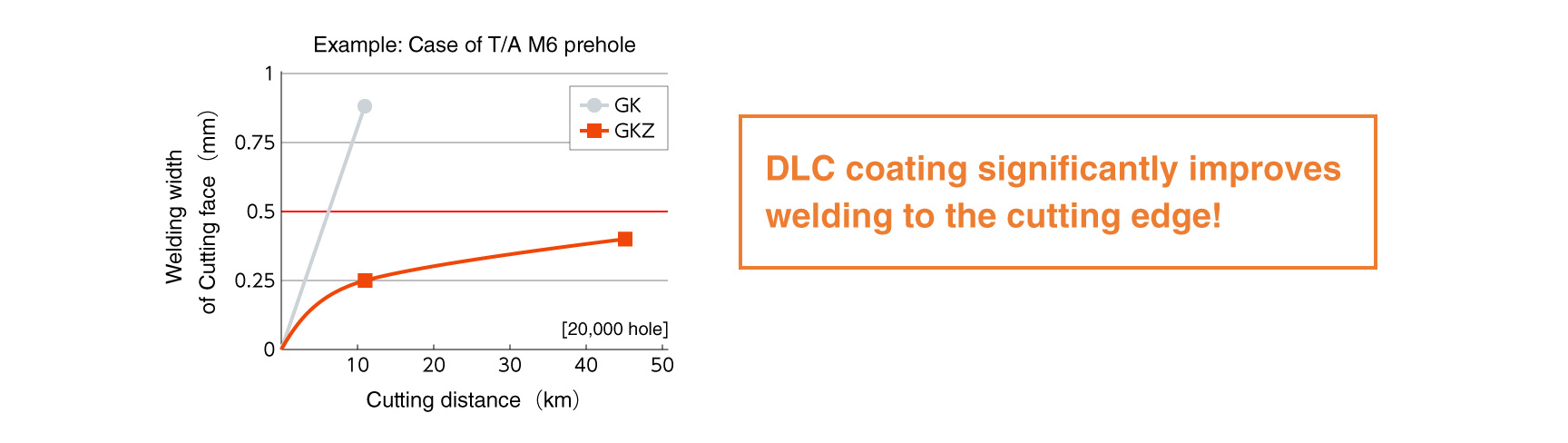

Improved welding resistance to the cutting edges with DLC coating

POINT!

High guiding performance with double margins, and special thinningExcellent !

POINT!

The effect of 3 edges! Excellent hole positioning in casted holes!Good !

Background / Point for Development

Background

- Twist drills have been the conventional and mainstream drills for general hole drilling of aluminum.

- However, twist drills tend to have low tool rigidity, which causes the drill to make unwanted move, resulting in hole bending and chattering.

Point for Development

- The GK series uses thinning and double margins, best suited for aluminum to eliminate undesired tool behaviours, thereby reducing bending and chattering.

- The GK series also offers special shapes such as multi-step and double-margin specifications, and a line-up of DLC-coated products with high welding resistance.

Product Specification

GK Drill

Tool Specification

| Process covered | Alminum general holes Tap preholes / w/o preholes |

|---|---|

| Diameter | ø4 - |

| Standard conditions |

|

| Performance | IT9 |

GKT Drill

Tool Specification

| Process covered | Alminum general holes Tap preholes / casted holes |

|---|---|

| Diameter | ø6 - |

| Standard conditions |

|

| Performance | IT9 |