G-one HolderPAT.P

A Solution to the problem of

multi-blade boring cutters

- One-shot machining for high precision & high efficiency made possible by its special designed structure.

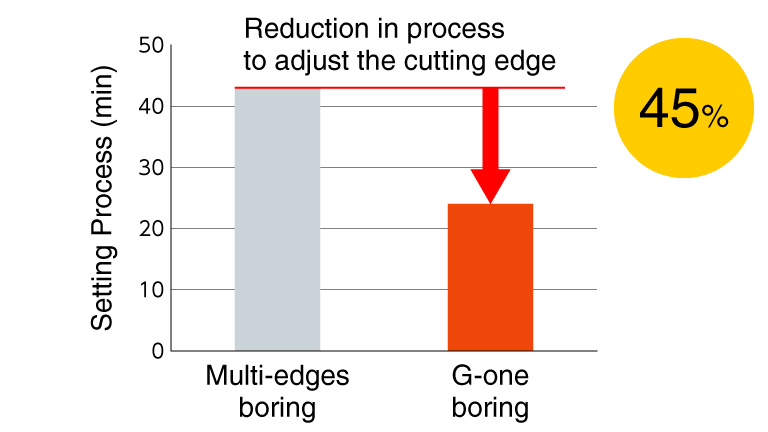

- NO need of edge run out adjustment

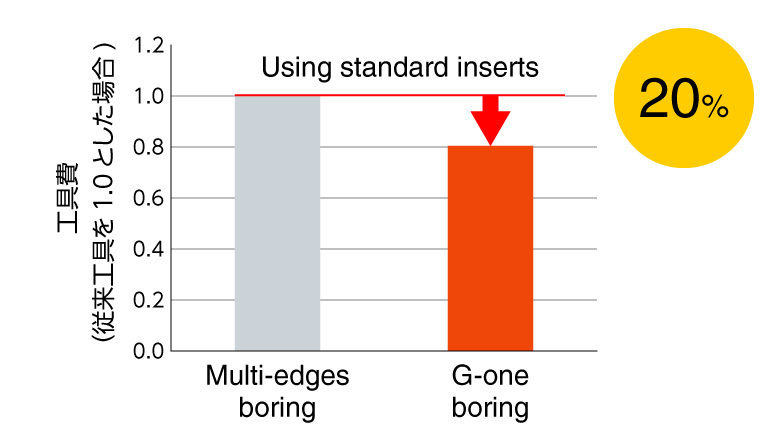

→ 45% setting time reduction - Use of standard inserts

→ 20% cost reduction - A single cutting edge

→ improves machining accuracy

![]()

“Amazing Ideas / Facts!”

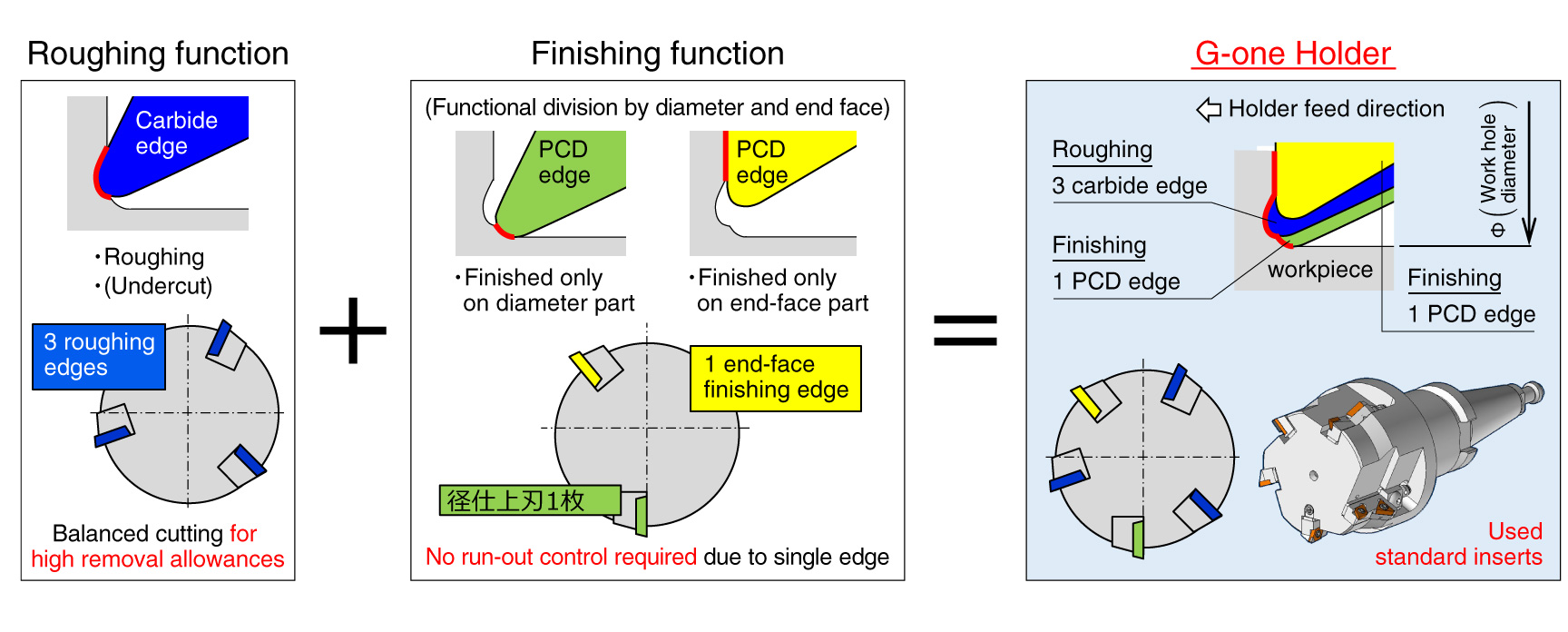

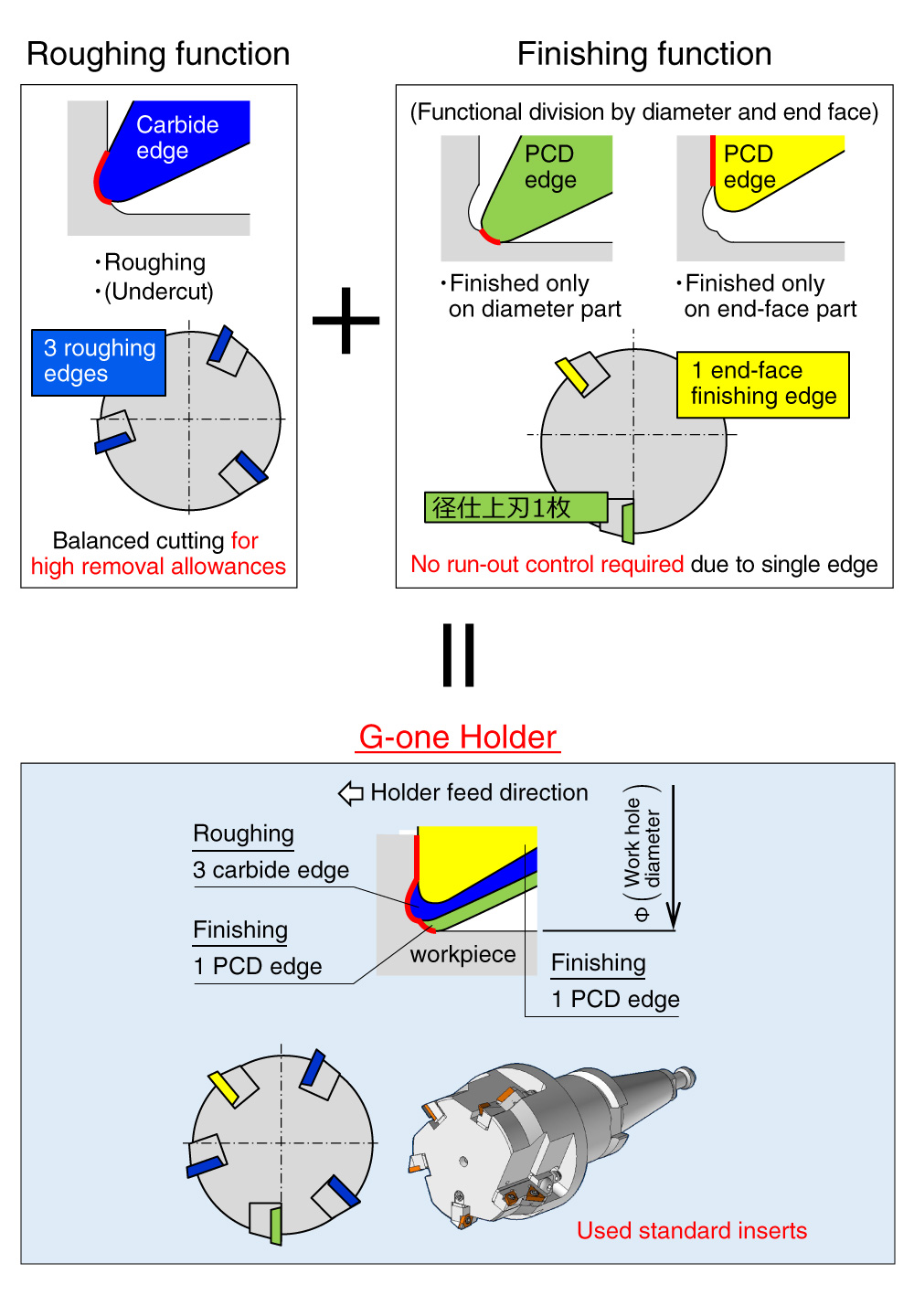

The G-one holder consists of roughing and finishing edges.

By using a single finishing edge and standard inserts for roughing, the setting time is largely reduced (no need of skilled workers to set up).

Hence high productivity, high-precision machining and reduced costs are achieved.

Setting Time ReductionGood !

Cost ReductionGood !

POINT!

Dividing the role of the cutting edge by functionExcellent !

Background / Point for Development

Background

- One shot machining with multi edged tools (instead of conventional rough & finish)has been established for high accuracy aluminum machining, to reduce the cycle time.

- However, “multi edges” always required longer setting up time and the run out adjustment.

Point for Development

- The G-one Holder integrates multiple cutting edges into a single holder.

By articulating each edge's function, it successfully reduced the setting up time and minimizing the total tools cost.

Example

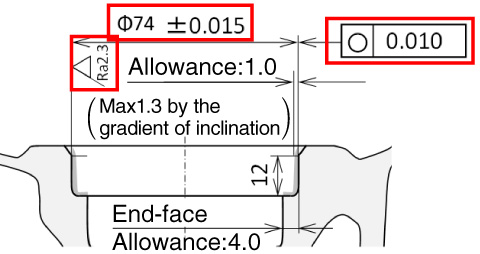

| Workpiece | Transmission case, bearing holes |

|---|---|

| Material | ADC12 |

| Tool Diameter | ø74mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

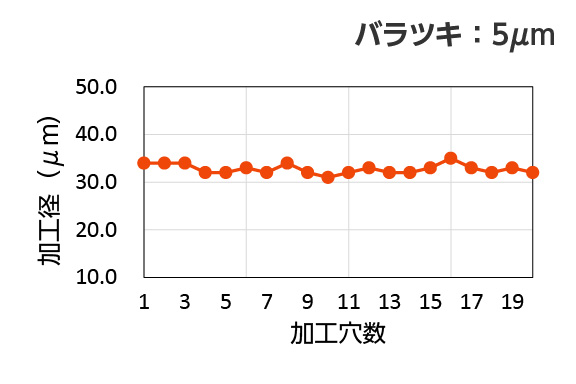

Changes in Hole Diameter

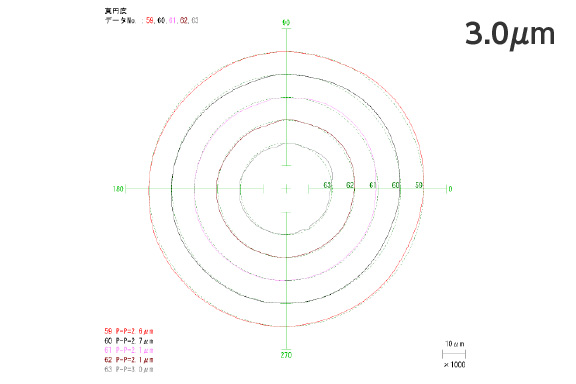

Roundness

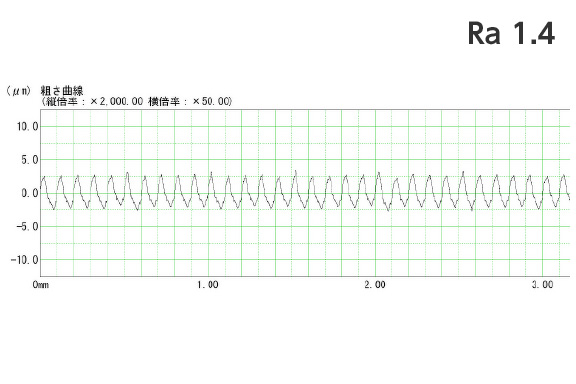

Surface Roughness

Product Specification

Tool Specification

| Process covered | Aluminium high-precision boring process *One-shot machining from plain/solid material |

|---|---|

| Diameter | ø55 - |

| Standard conditions |

|

| Performance | IT7 Roundness: 5µ |

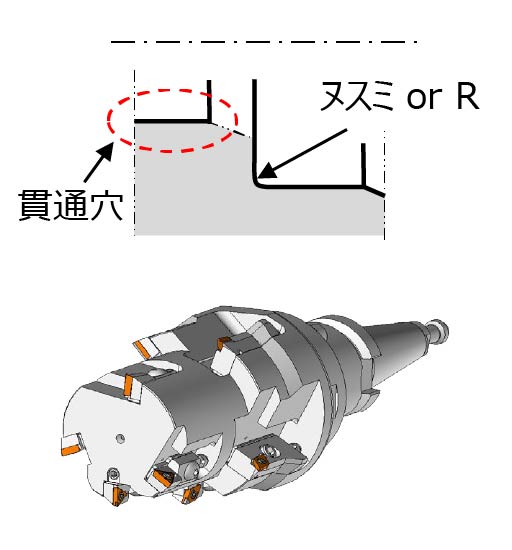

Example of applicable work

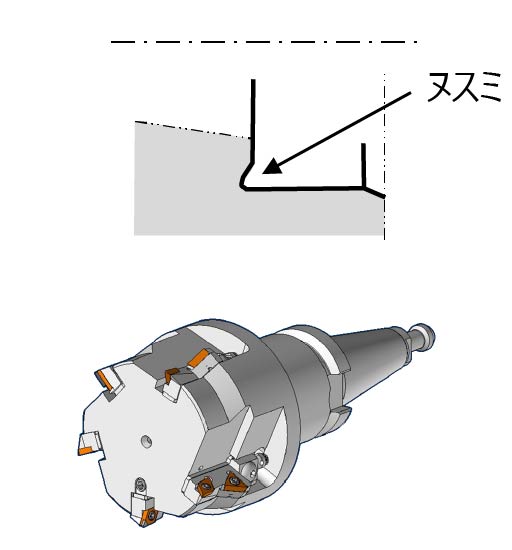

Undercut shape

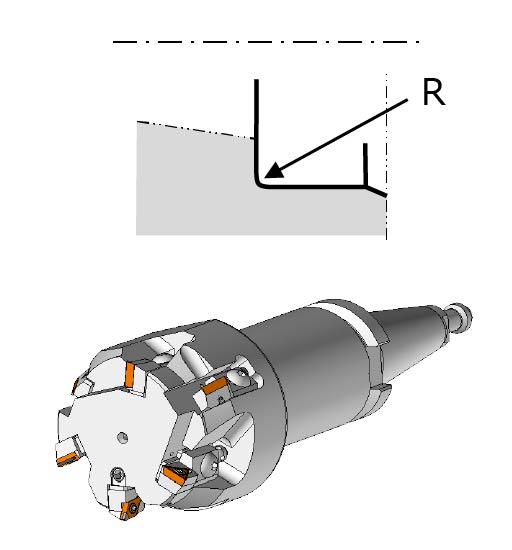

Corner R

Through hole