GP Drill series

One-shot machining and IT8

grade hole diameter accuracy with

our PCD drill series!

- Optimal tool specifications for each material shape,

from w/o preholes to casted holes!

- IT8 class one-shot finishing

- High accuracy, long life and high-speed machining with PCD edges

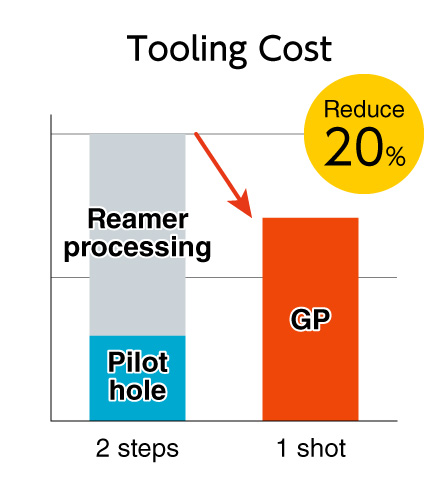

- Reduce tooling costs by reducing the number of used tools

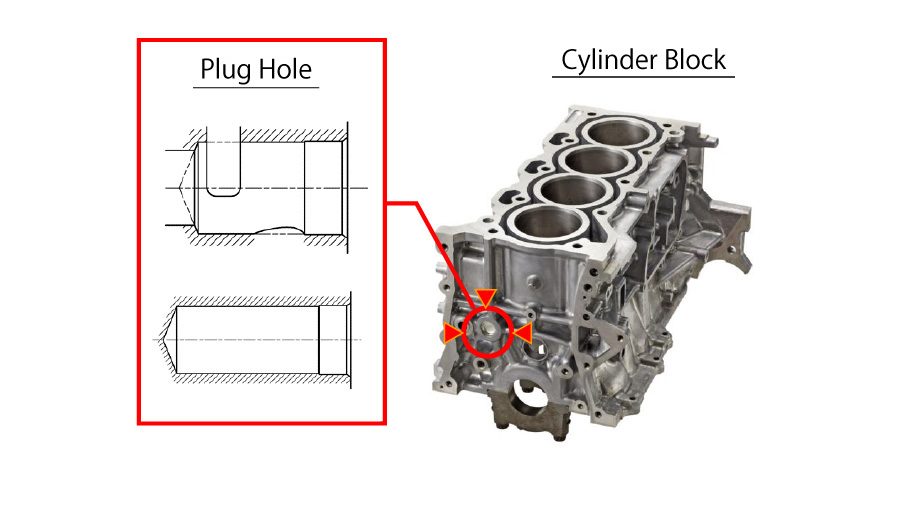

WHAT IS GP Drill series?

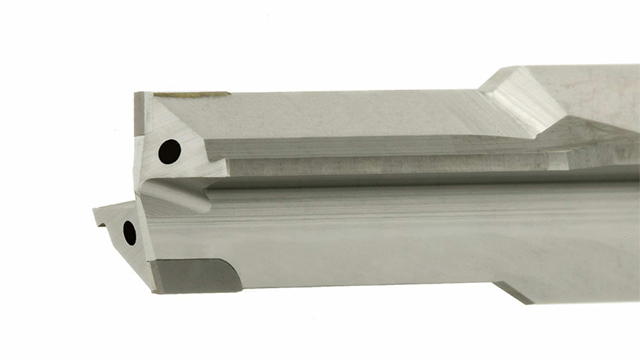

① GP Drill

For w/o prehole

Feature: high-precision machining with PCD edges

- PCD edge: 2

- Accuracy: IT8

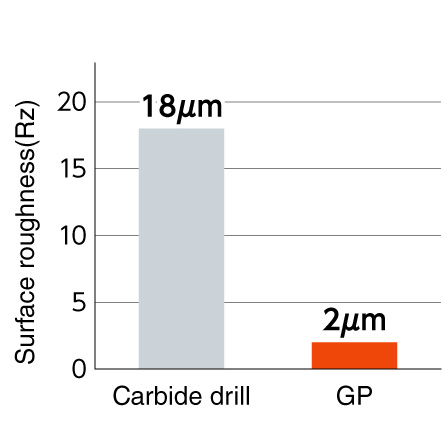

- Surface roughness: ≤ 3.2z

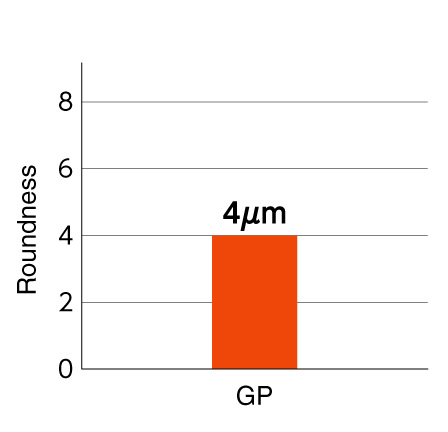

- Roundness: ≤ 8µm

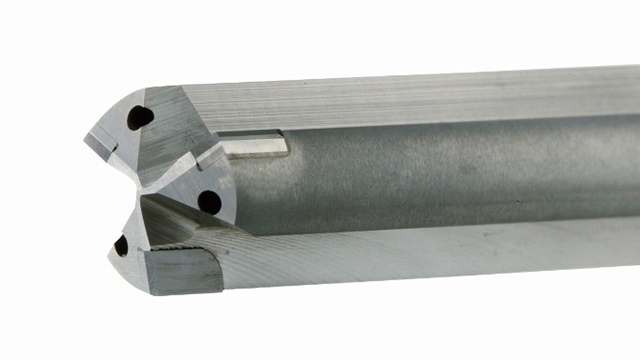

② GPT Drill

For casted hole

Feature: Stable machining with casted holes

- PCD edge: 3

- Accuracy: IT8

- Surface roughness: ≤ 3.2z

- Roundness: ≤ 8µm

“Amazing Ideas / Facts!”

The GP drill series uses PCD as the cutting edge material.

It has high welding resistance against aluminum and enables stable machining accuracy even in one-shot machining.

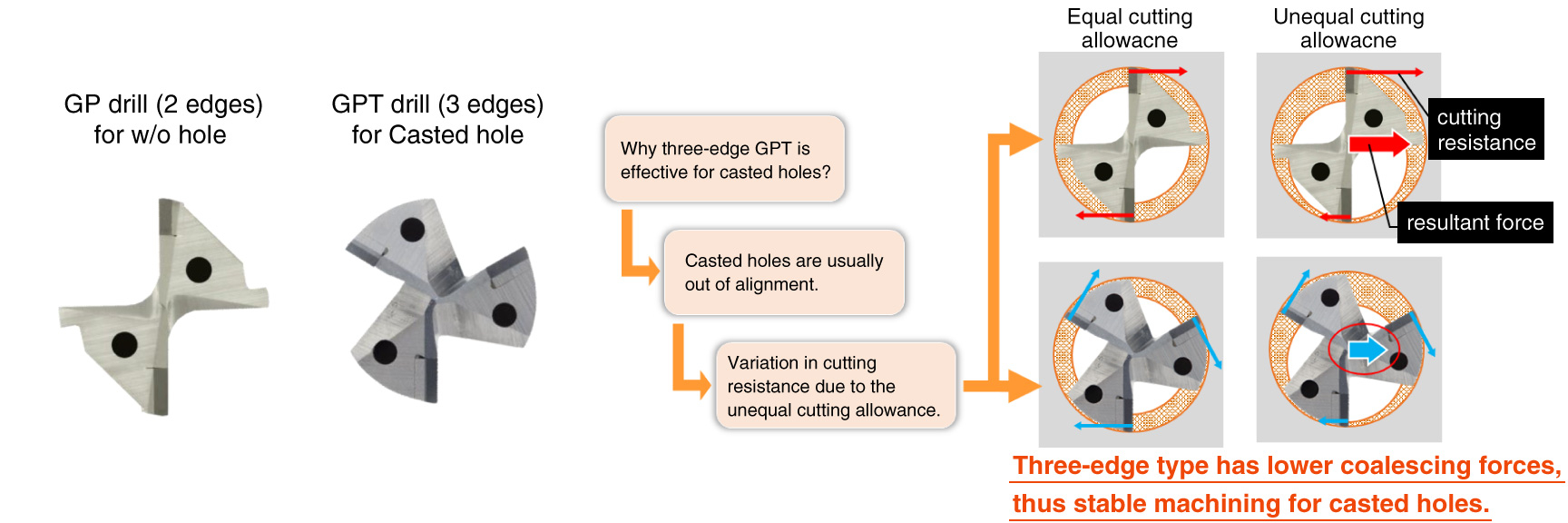

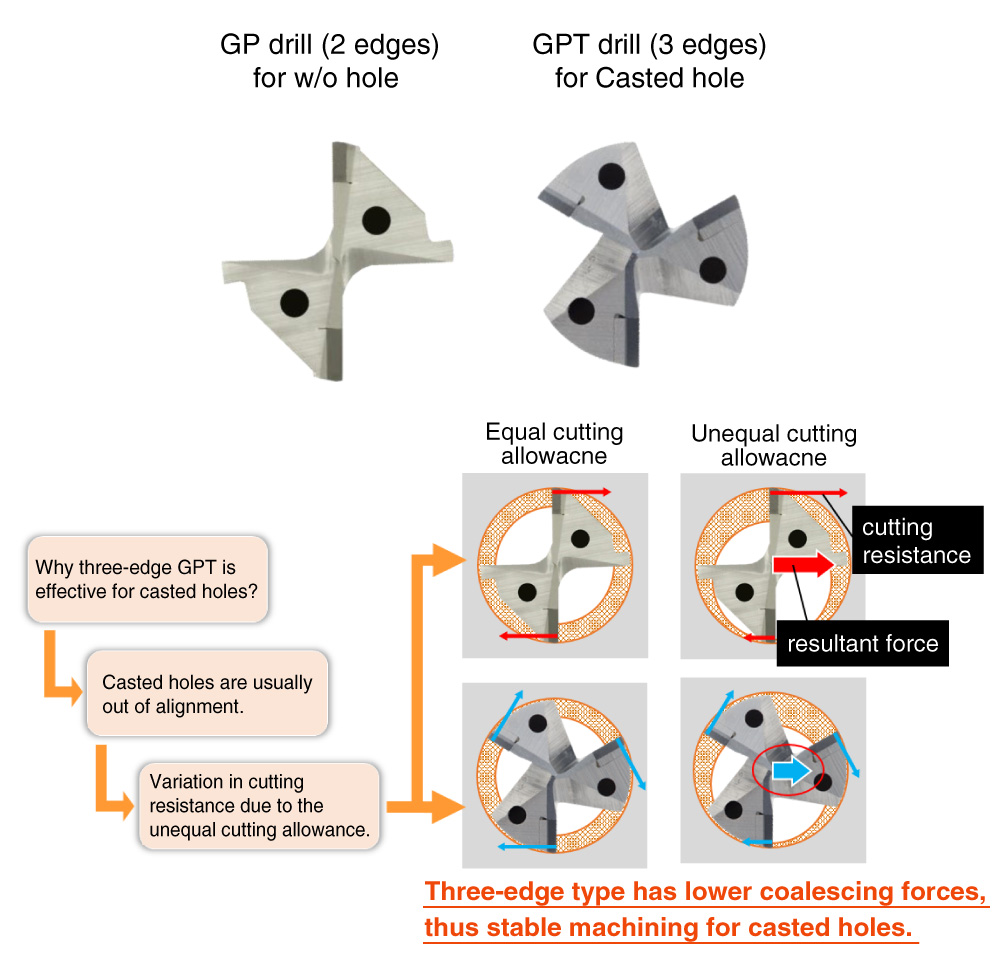

Our line-up includes a 2-edge GP drill for w/o prehole drilling and a 3-edge GPT drill for casted hole drilling.

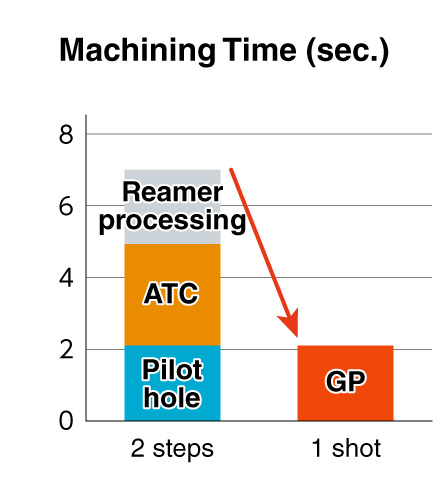

By using the GP Drill Series, one can reduce machining time and tool costs in processes that conventionally require two steps.

High Precision with Diamond EdgesGood !

Process Time ReductionGood !

Cost Reduction

Good !

POINT!

Different number of cutting edges for machining w/o preholes or casted holeExcellent !

Background / Point for Development

Background

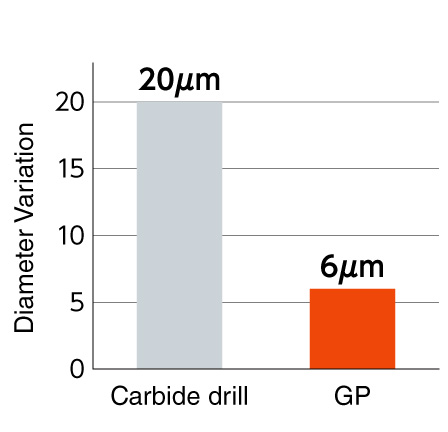

- With conventional carbide tools, one-shot machining was difficult due to the problem of aluminium welding onto the cutting edges.

- The development of net-shape casting technology has increased the number of workpieces with casted holes in the industry. 2-edged GP drills however, had problems with inconsistent accuracy from machining the casted holes.

Point for Development

- The GP drill with PCD edges, which have high resistance to aluminum welding, provides stable accuracy in one-shot machining.

- The GPT drill has 3 PCD cutting edges, which is apt for achieving more stable accuracy in machining casted holes.

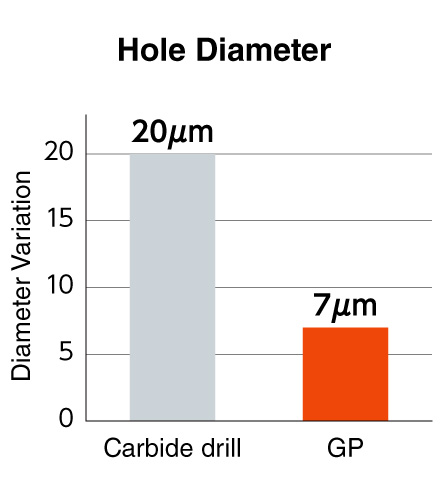

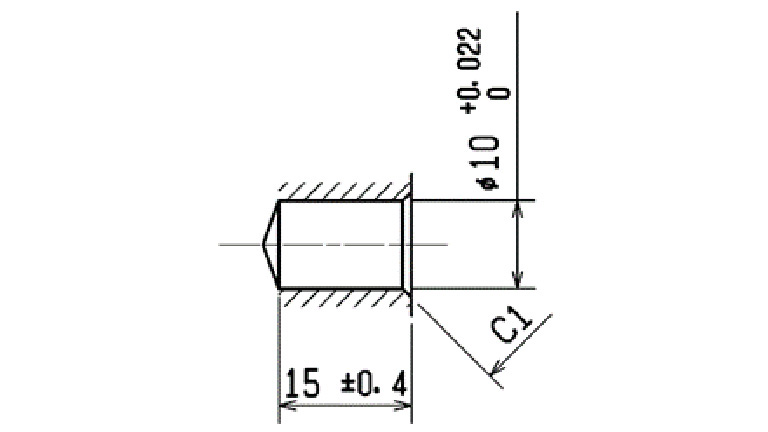

Examplew/o prehole

| Tool | GP drill |

|---|---|

| Workpiece | Aluminum block |

| Material | ADC12 |

| Tool Diameter | ø10mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

Hole Diameter

Surface Roughness

Roundness

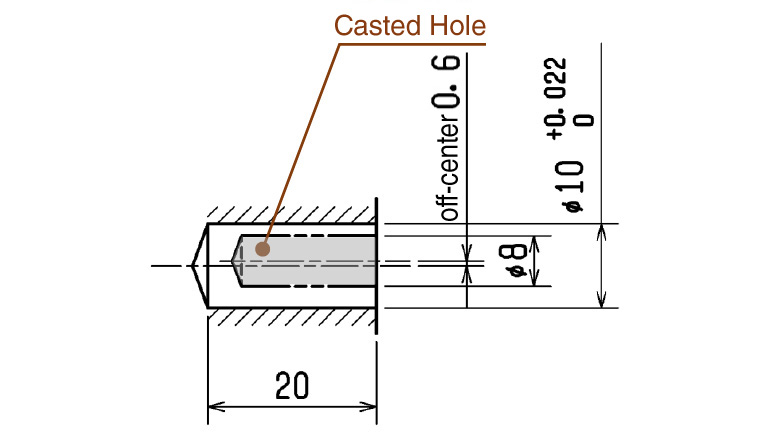

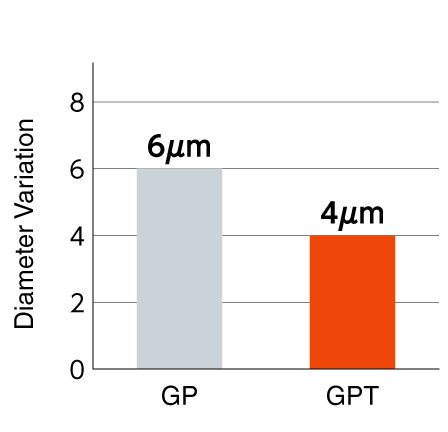

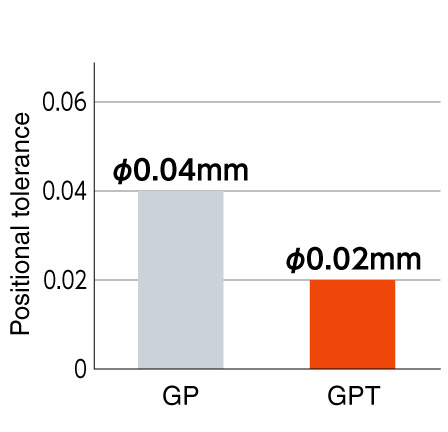

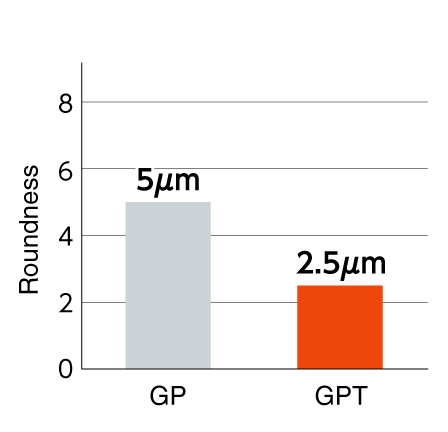

ExampleCasted Hole

| Tool | GPT drill |

|---|---|

| Workpiece | Aluminum block |

| Material | ADC12 |

| Tool Diameter | ø10mm |

| Cutting Conditions |

|

| Required accuracy |  |

|---|

Hole Diameter

Position

Roundness

Product Specification

GP drill

Tool Specification

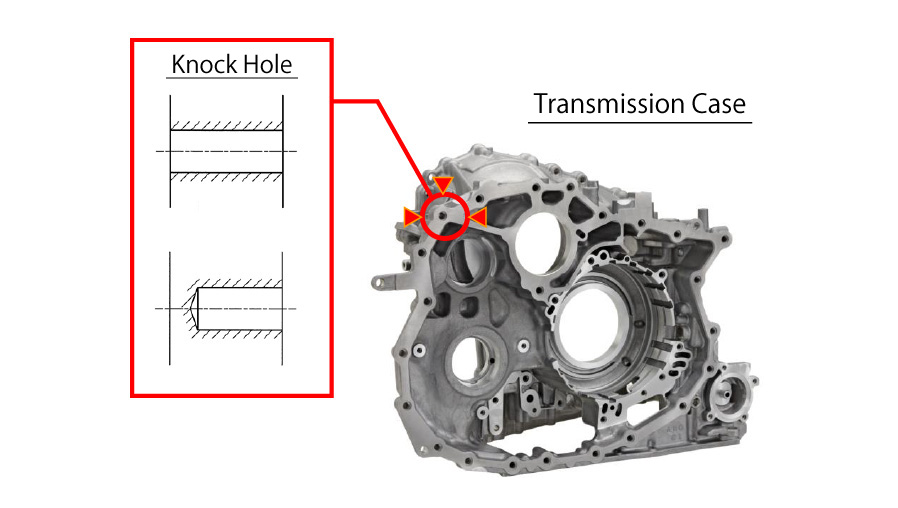

| Process covered | knock holes, plug holes Aluminum high-precision holes / w/o preholes *One-shot machining from plain/solid material |

|---|---|

| Diameter | ø5 - |

| Standard conditions |

|

| Performance | IT8 |

Example of applicable work

GPT drill

Tool Specification

| Process covered | knock holes, plug holes Aluminum high-precision holes / w/o preholes *One-shot machining from plain/solid material |

|---|---|

| Diameter | ø6 - |

| Standard conditions |

|

| Performance | IT8 |

Example of applicable work