High Precision

Work Chuck Jig

Essential items for gear processing!

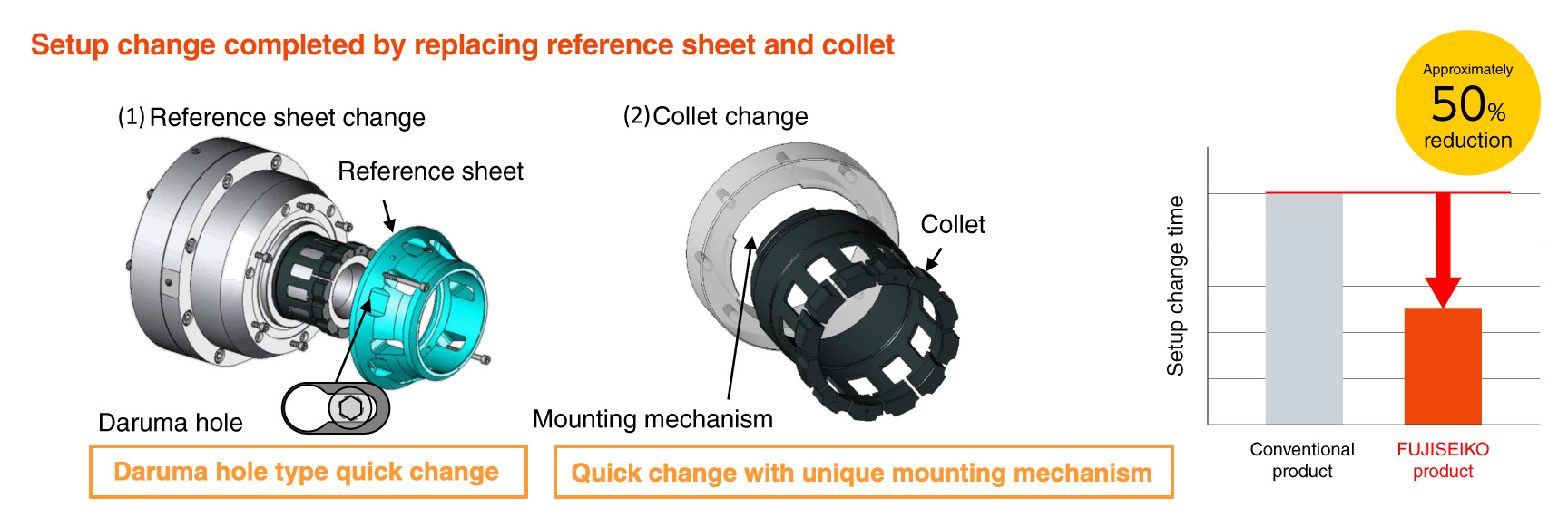

- Collet chuck designed for high precision and

shortening changeover time.

- Chucking runout accuracy ≤ 10 microns.

- Supports multi-product production by adopting quick change mechanism

“Amazing Ideas / Facts!”

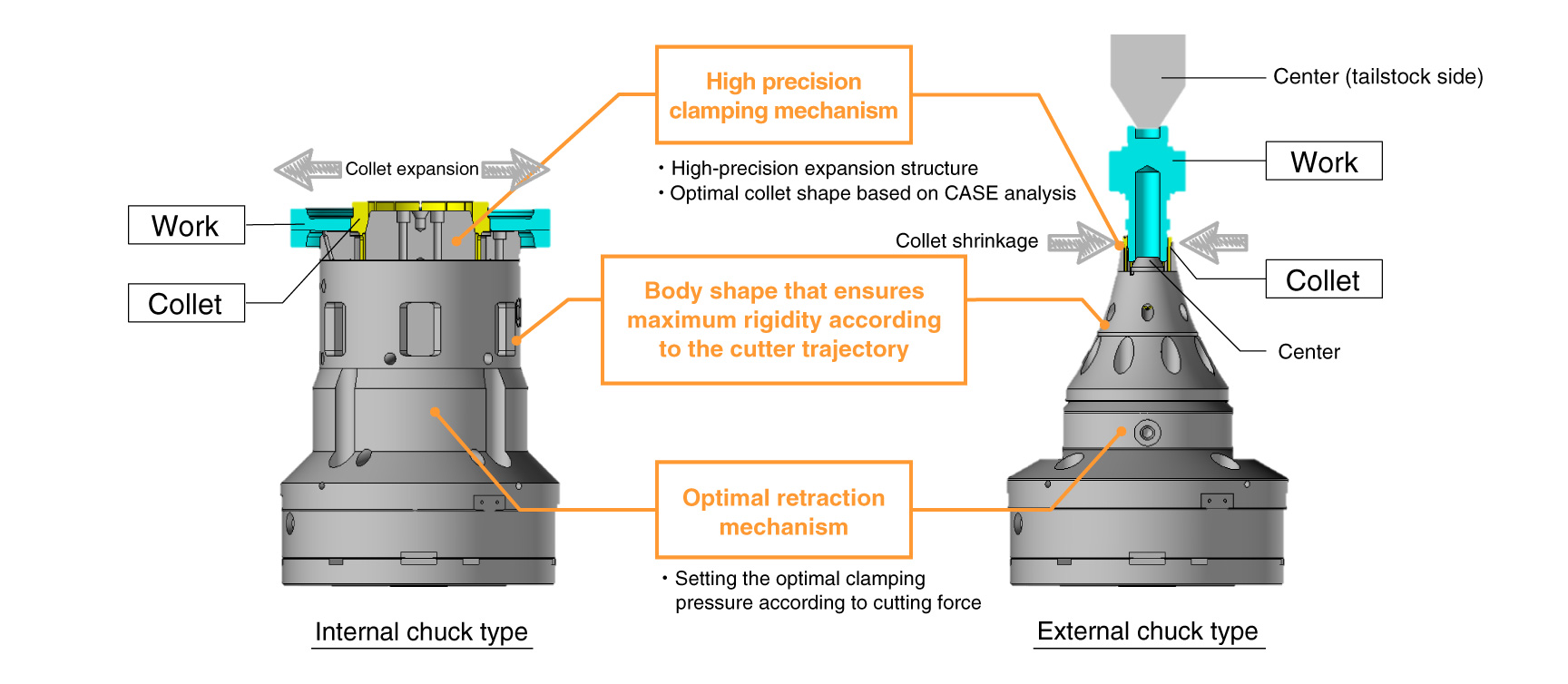

The “high-precision workpiece chuck” is a clamping jig with expanding / contracting collet:

- The body shape to match the cutter's machining trajectory.

- The clamping pressure set according to the cutting force.

- Use of CAE analysis.

Various quick change mechanisms available for easy setup changes and for a wide variety of products, while the runout accuracy is kept and the setup / changing time reduced.

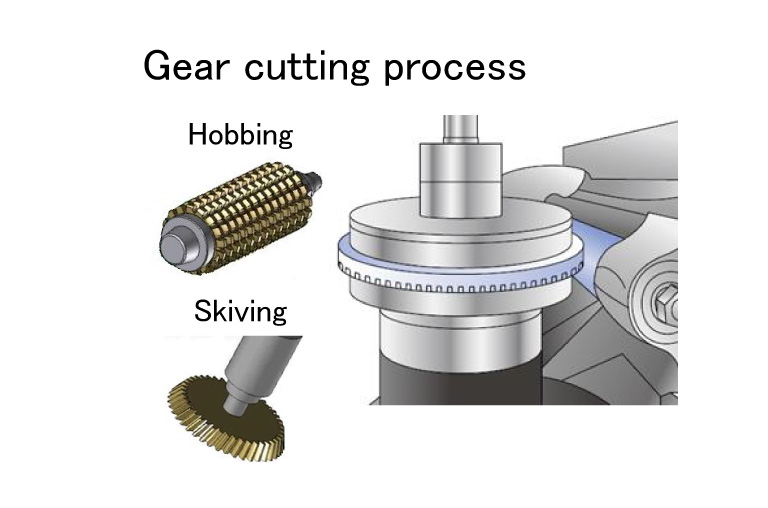

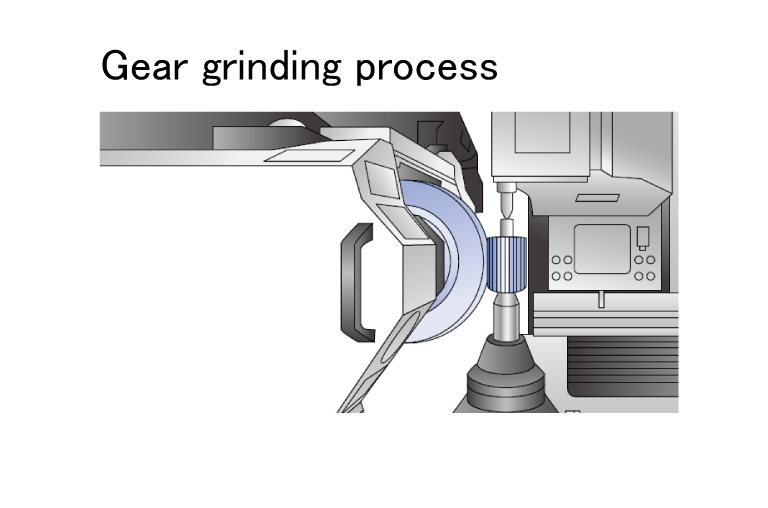

Process covered: Gear cutting (hobbing, skiving), Gear grinding

Structure and features

POINT!

The uniquely designed jig for the change of product typesExcellent !

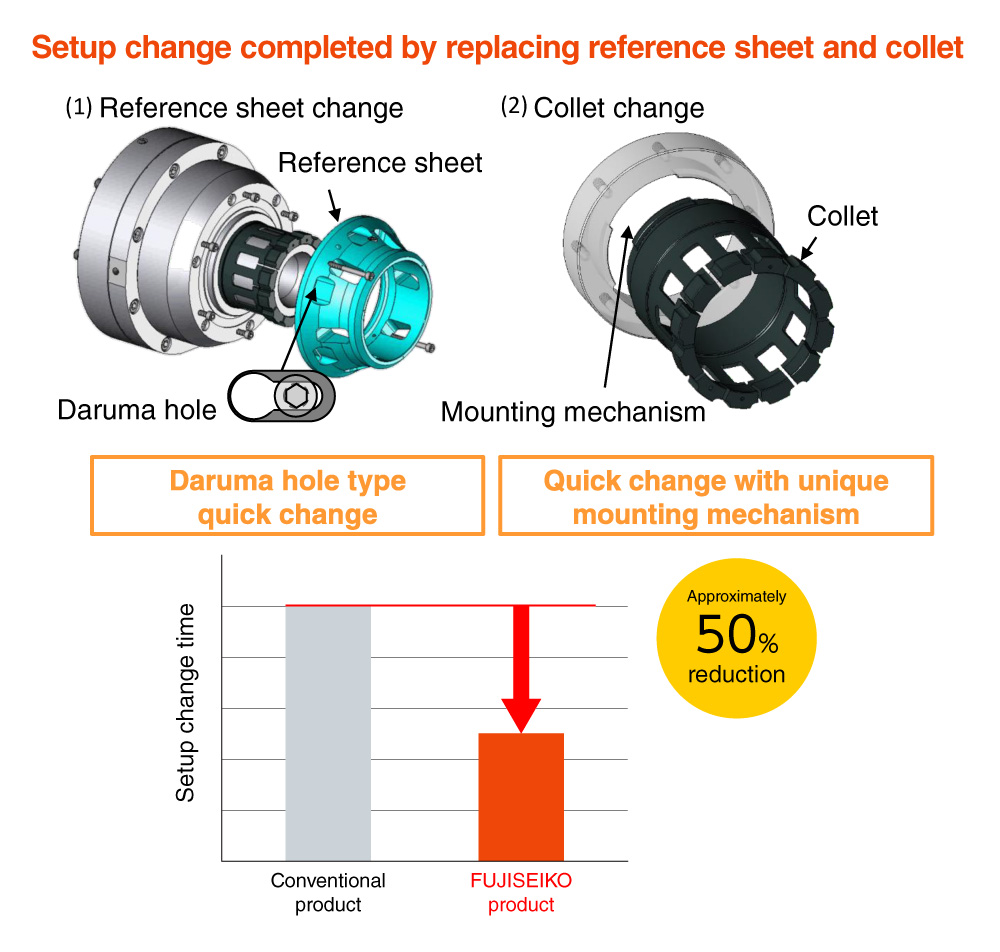

Quick change of parts

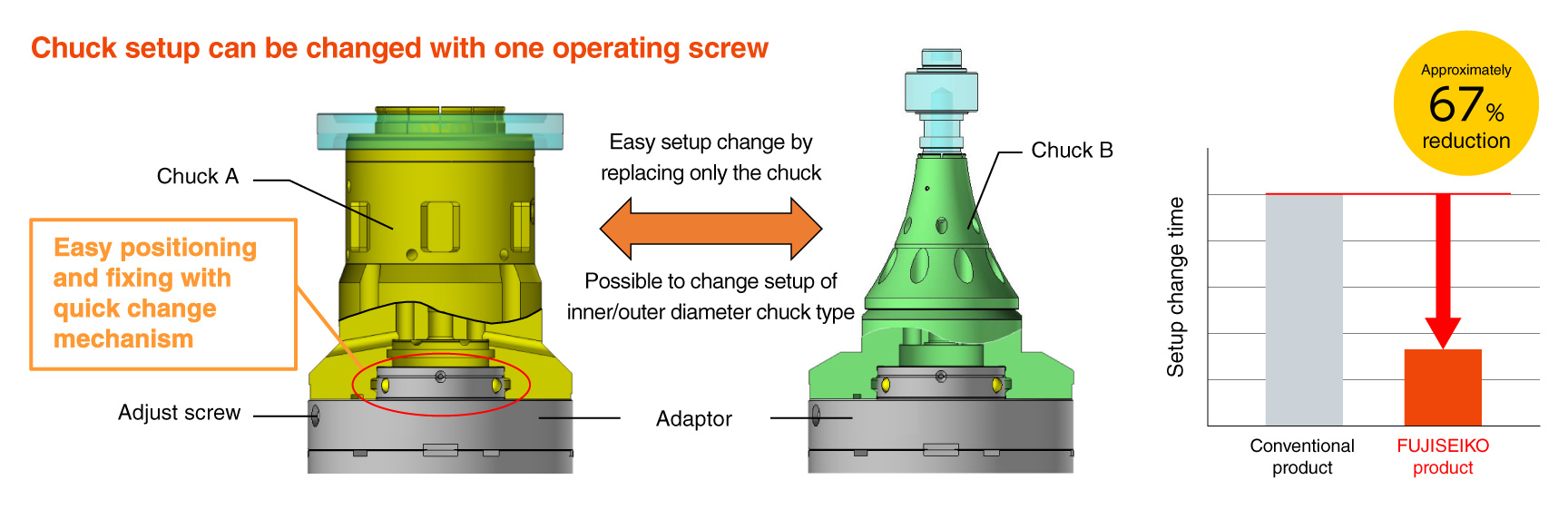

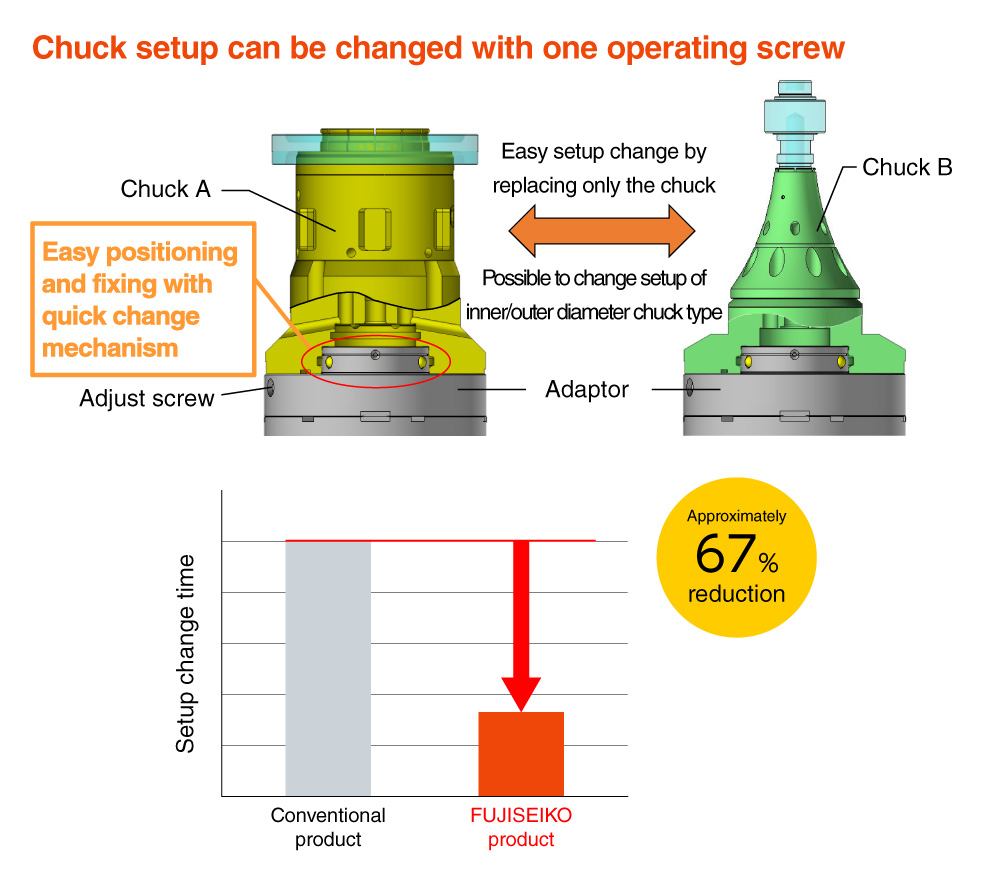

Quick change of chuck

Background / Point for Development

Background

- Electric vehicles are required to have highly accurate transmission gears so that the motor can be driven with high efficiency. For this reason, precision machining is essential, especially in the gear cutting and gear grinding processes. As the need for multi-product production increases, the need is increasing for easy & quick replacement of jigs.

Point for Development

- The optimal clamping mechanisms, body shapes, and clamping forces integrated into this “high-precision workpiece chuck jigs”

- The quick-change mechanism for multi-product production, reducing both time & man powers.