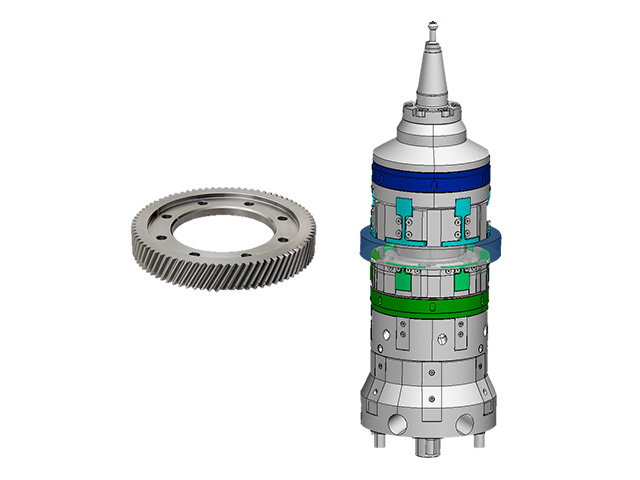

Flexible Jig

for Hobbing

This is the one for hobbing!

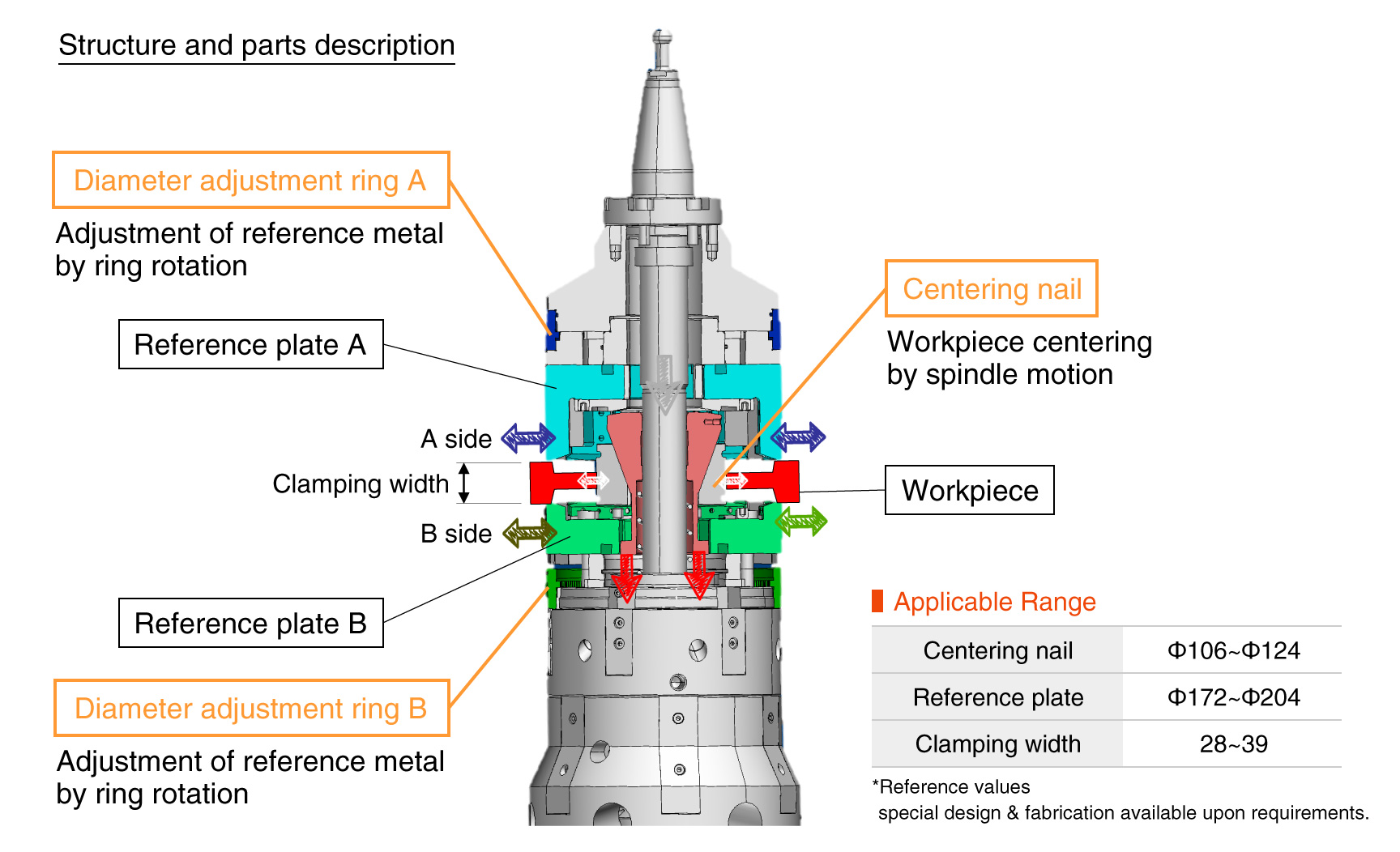

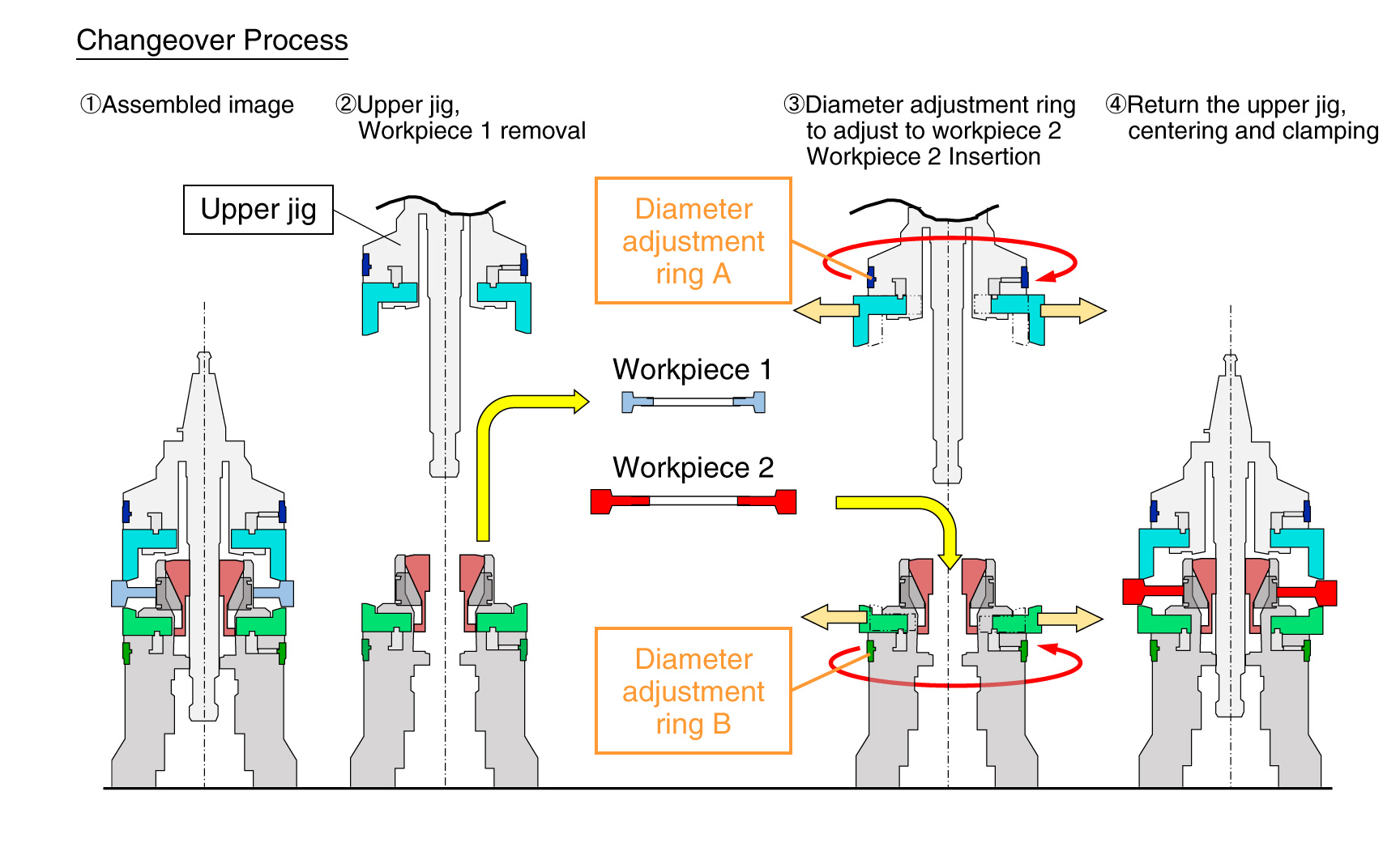

- Tool changeover using a clamp diameter adjustment mechanism.

- Applicable to a wide variety of products with minimized setting up time.

- Flexible adaptation to a wide variety of workpieces

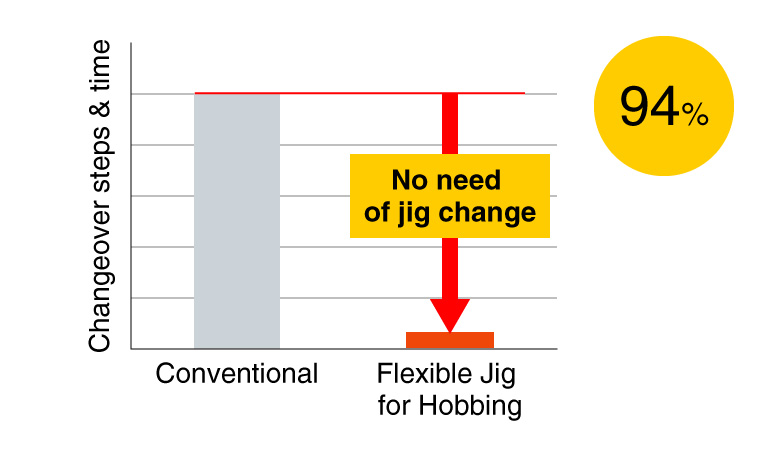

- Easy operation reduces changeover steps by 94%!

- No parts replacement is required!

“Amazing Ideas / Facts!”

A single “Flexible Jig for Hobbing” can clamp various types of workpieces by its special clamp diameter adjustment and centering mechanism.

The diameter can be adjusted simply by turning the diameter adjustment ring without the need to replace any parts, enabling quick and easy setup work and resulting in less investment cost.

Investment reductionGood !

Reduction of changeover man-hoursGood !

POINT!

Easy and quick changeover: No need for extensive jig replacement!Excellent !

Background / Point for Development

Background

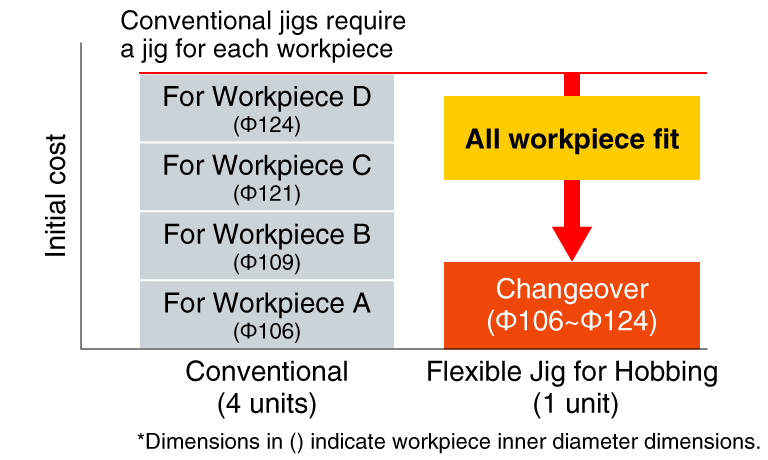

- Conventionally, the hobbing machine requires a jig change for each workpiece type, which takes time for each set up.

The need to prepare a jig for each workpiece type results in a large cost.

Point for Development

- The “Flexible Jig for Hobbing” enables variable workpiece centering and the ring for diameter adjustment, made possible to handle multiple types of workpieces with a single jig.

→ investment reduction

→ Set up time reduction