Mandrel (Hydraulic/Slide Key Type)

For chucking ring-shaped products

during measurement/machining!

- Easy operation with a single wrench!

- Runout accuracy is less than 5µm (with Master ring)

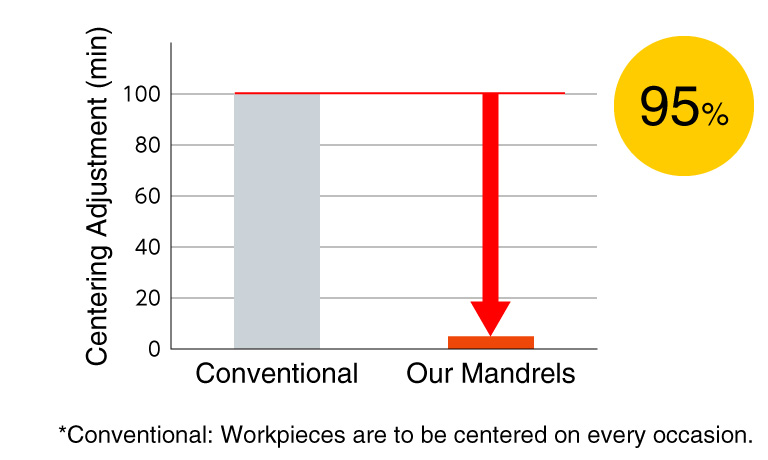

- 95% reduction of centering time

- High accuracy by inexpensive mechanism (runout accuracy 5 µm or less)

- The same main unit can be used for a wide variety of products

“Amazing Ideas / Facts!”

Easy operation with a single wrench reduces the time required for centering adjustment and realizes high-precision clamping, regardless of operator's skill.

Adopting to a wide variety of products (different shape of workpieces, equipment, etc).

By changing of collets, it can be used for a wide range of diameters.

“Easy,” “Highly accurate,” and “Flexible” at the same time.

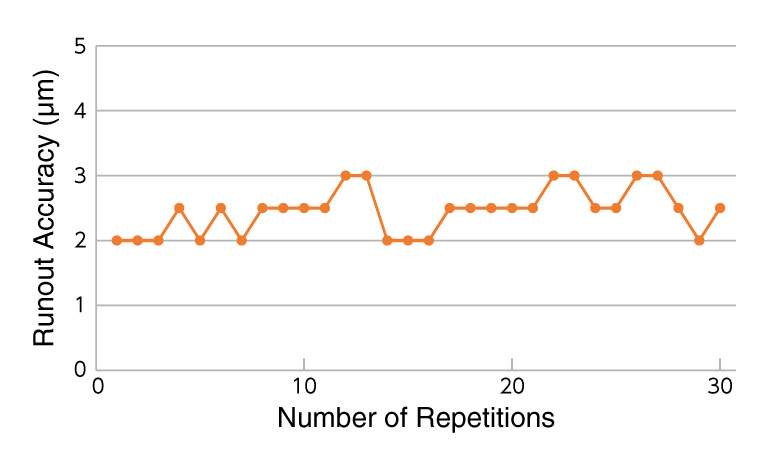

Excellent runout accuracy on chuckingGood !

Reduced centering adjusting timeGood !

POINT!

Easy and highly accurate: The same accuracy can be achieved by any operators!Excellent !

Background / Point for Development

Background

- In gear-processing, it was difficult to accurately measure workpieces during the machinings /measurements, and adjusting the centers of workpieces was time-consuming, required skilled operators.

The need for easier operation while still stable and high precision clamping were possible, not depending on operator's ability.

Point for Development

- The mandrel can be operated with a single wrench, greatly reducing the number of steps, required for the centering.

- The consistent runout accuracy, regardless of the operator's skill.

- Compatible in a wide range of diameters for multiple product types, by simply replacing collets.

- The often-demanded “Small-diameter type” is also available.

- ‘Easy operation,’ ‘high accuracy,’ and ‘flexibility’ are realized.

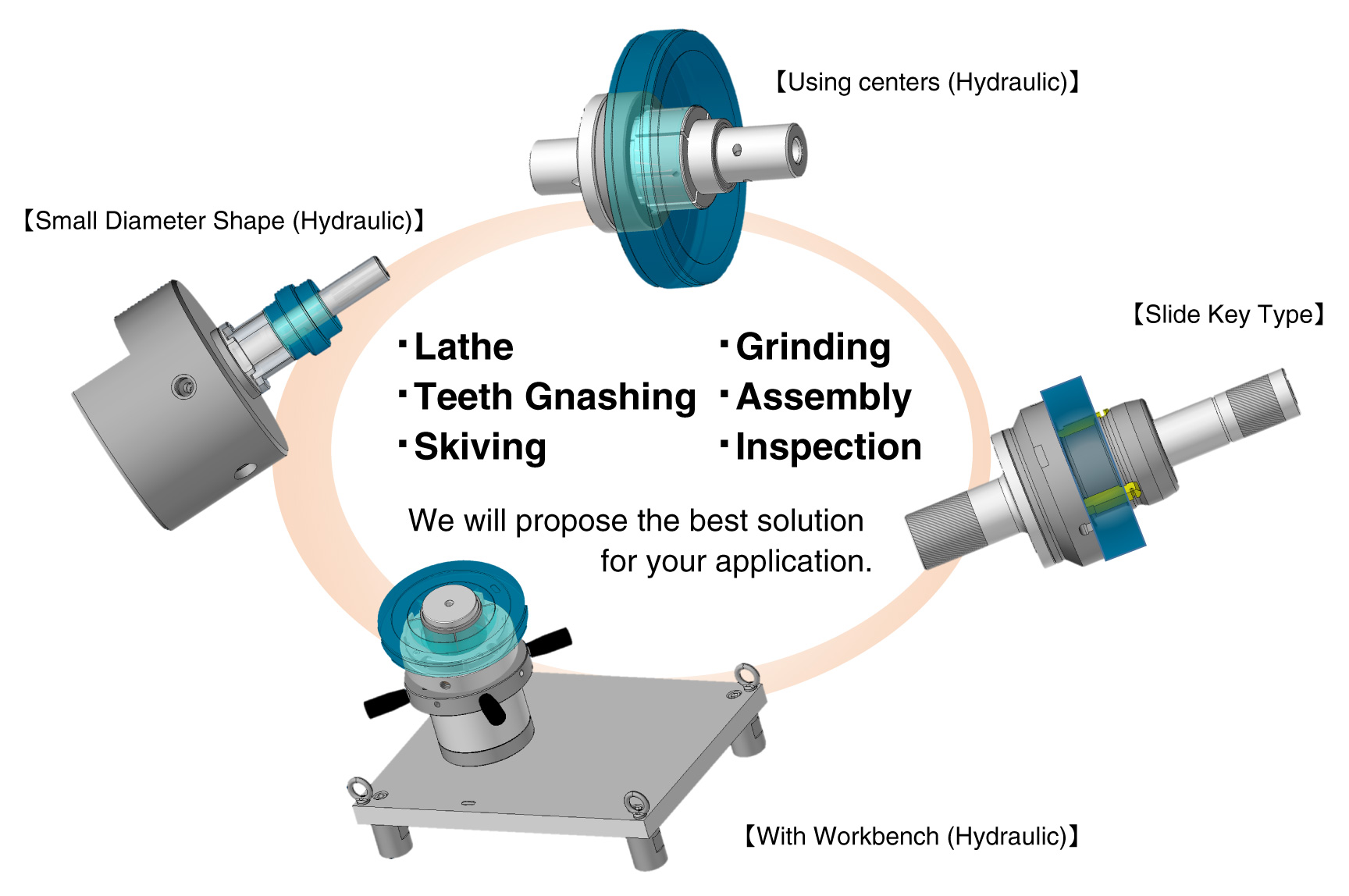

Examples of Utilization

Wide range of applications from machining to assembly and inspection

Product Specification

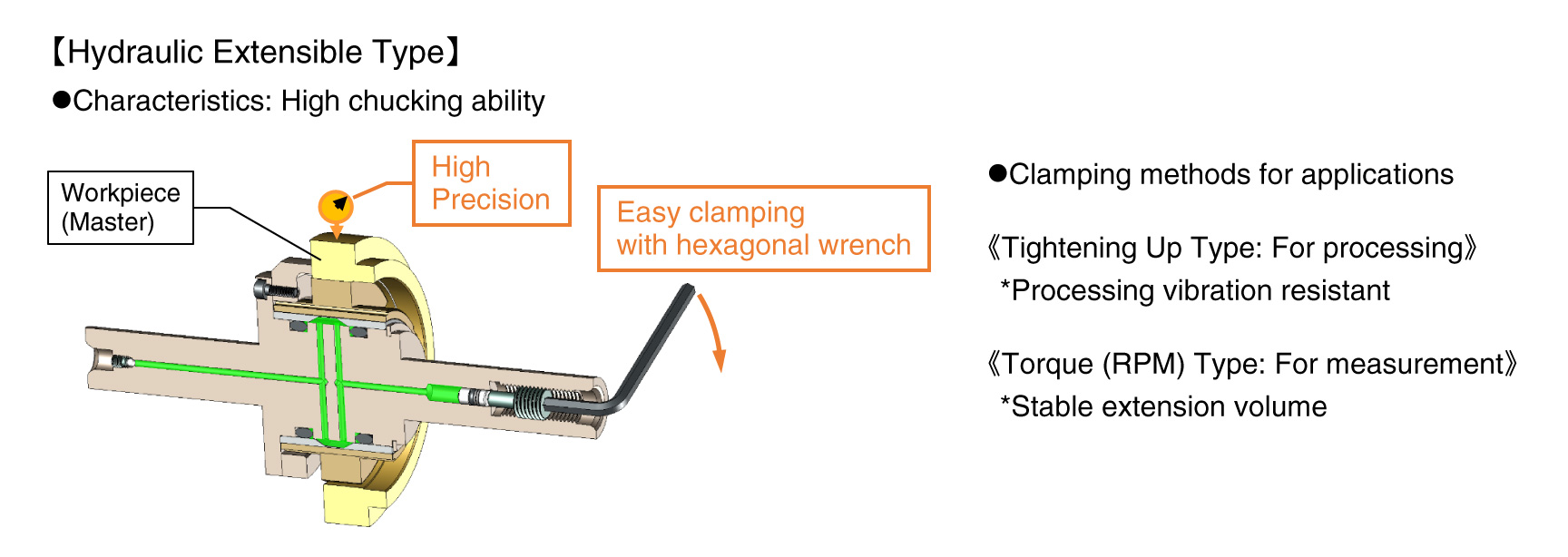

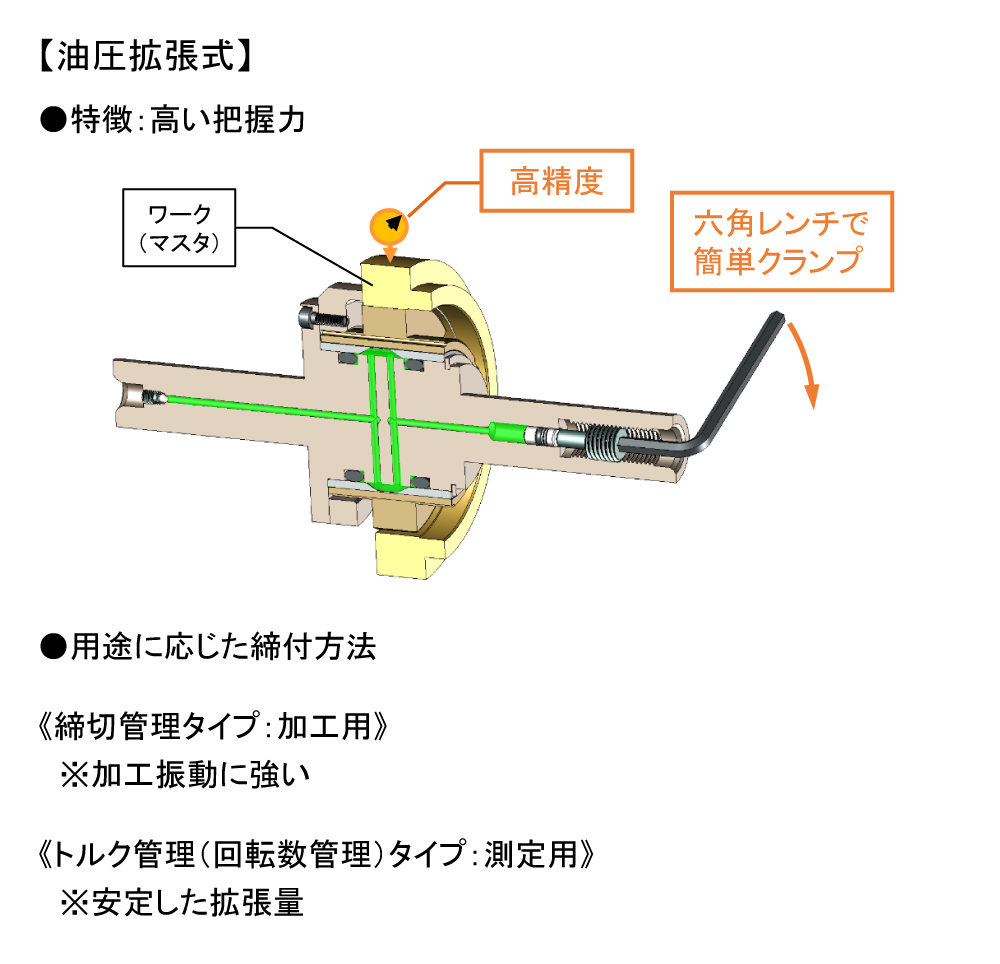

Hydraulic Extension Type

| Feature |

|

|---|---|

| Application | Turning/grinding, measurement |

| Extension volume | øD×0.003mm (ø0.06 extension in case of ø20) |

| Runout accuracy | Within 5 µm |

| Repeatability | Within 1 µm |

| Chucking Diameter | ø8 - ø200 |

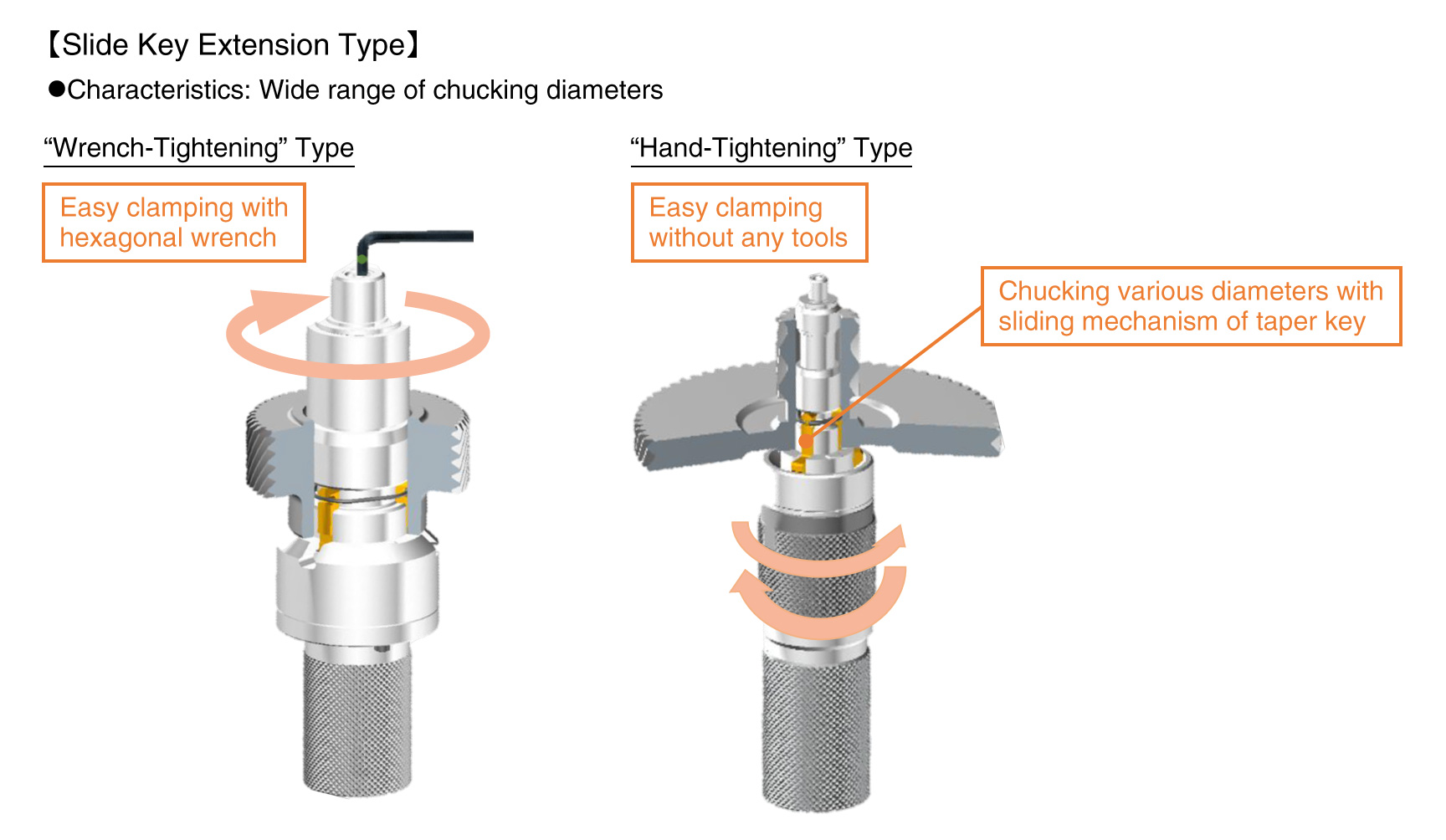

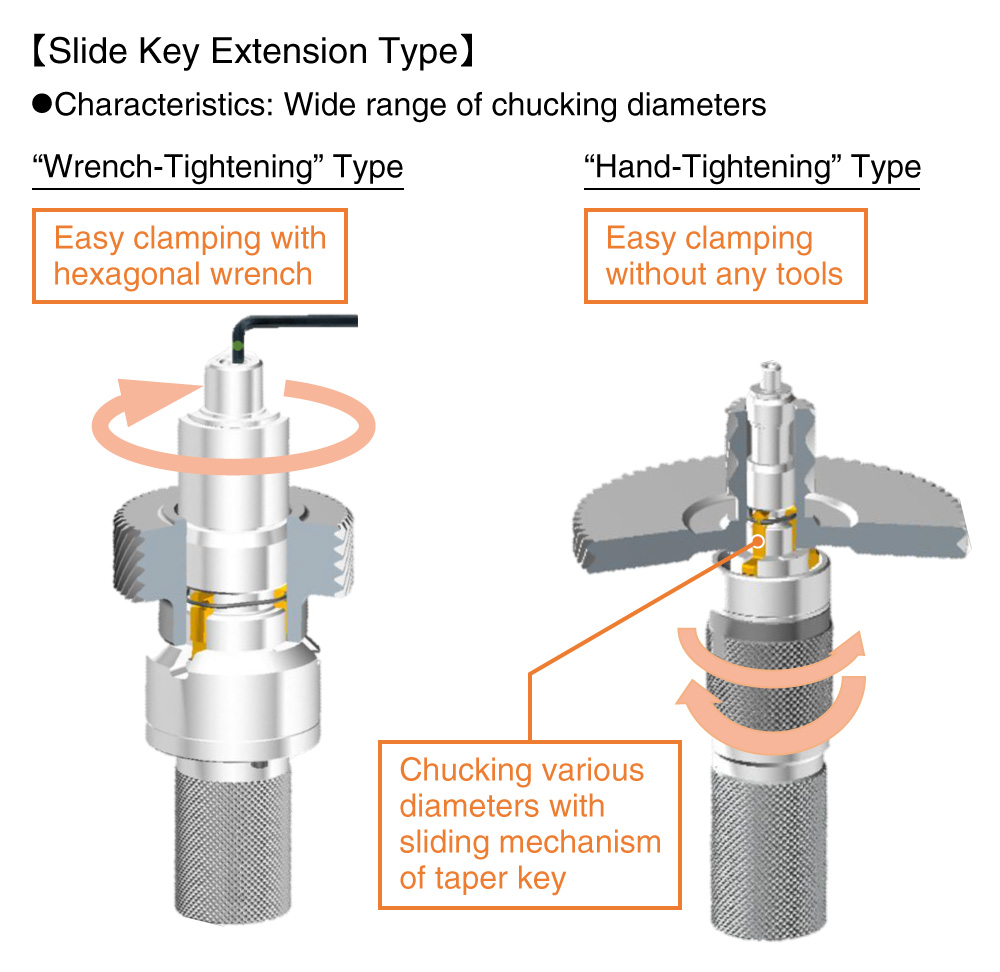

Slide Key Extension Type

| Feature |

|

|---|---|

| Application | Measurement |

| Extension volume | ø1.0mm (Customisable) |

| Runout accuracy | Within 5 µm |

| Repeatability | Within 1 µm |

| Chucking Diameter | ø18 - ø200 |