Material-Handling Series

Automatic changeover greatly

increases the operational efficiency!

- Workpiece transport and jig changeover within a machining center, a step forward to the “Manufacturing Automation”

- Simply attach to a M/C

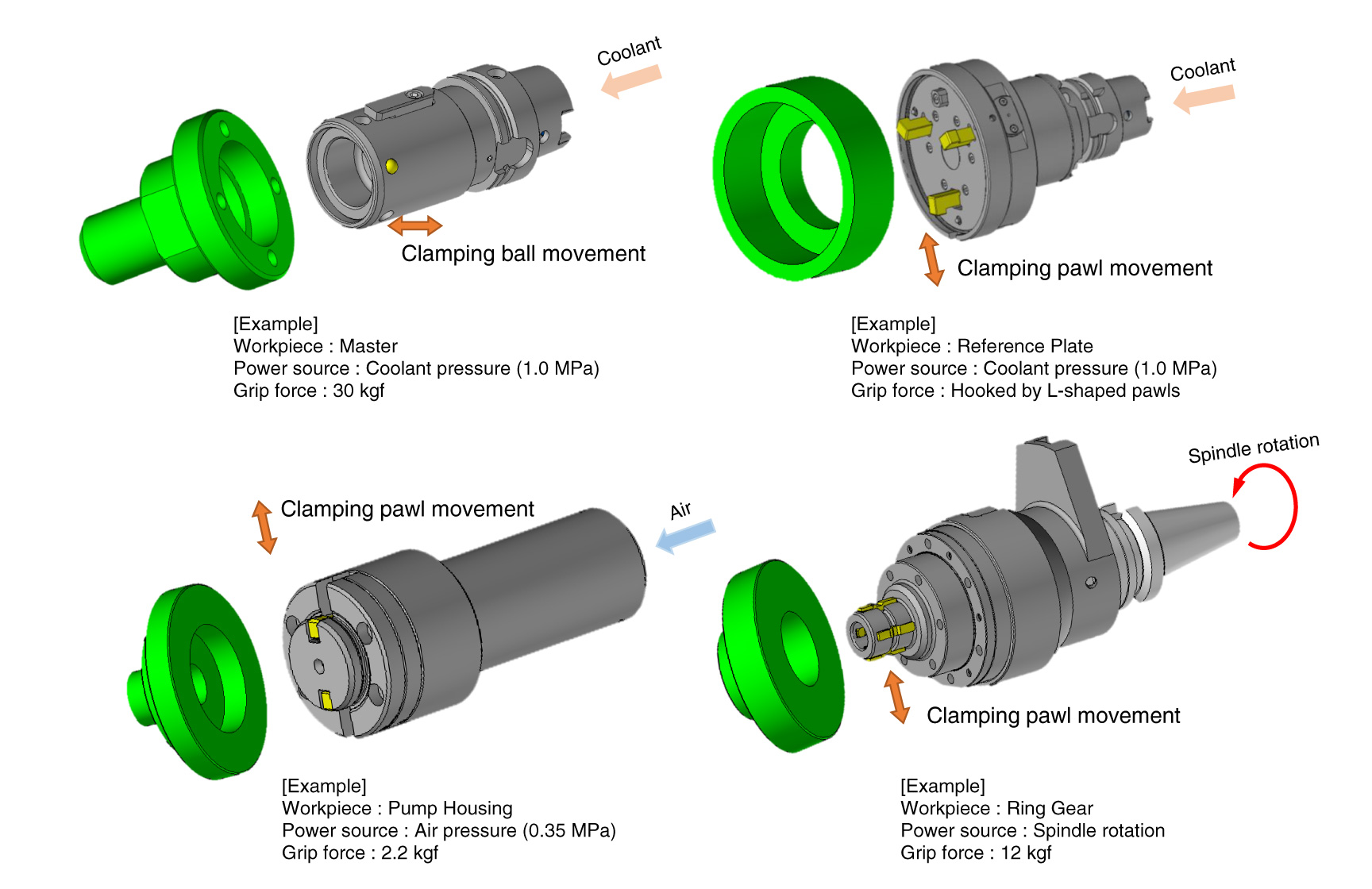

- Operable by coolant pressure, air, or spindle rotation power

- Variety of clamping variations for different applications

“Amazing Ideas / Facts!”

The “Material-Handling Series” utilizes coolant pressure, air, or spindle power to clamp workpieces and jigs by simply installing in a machining center.

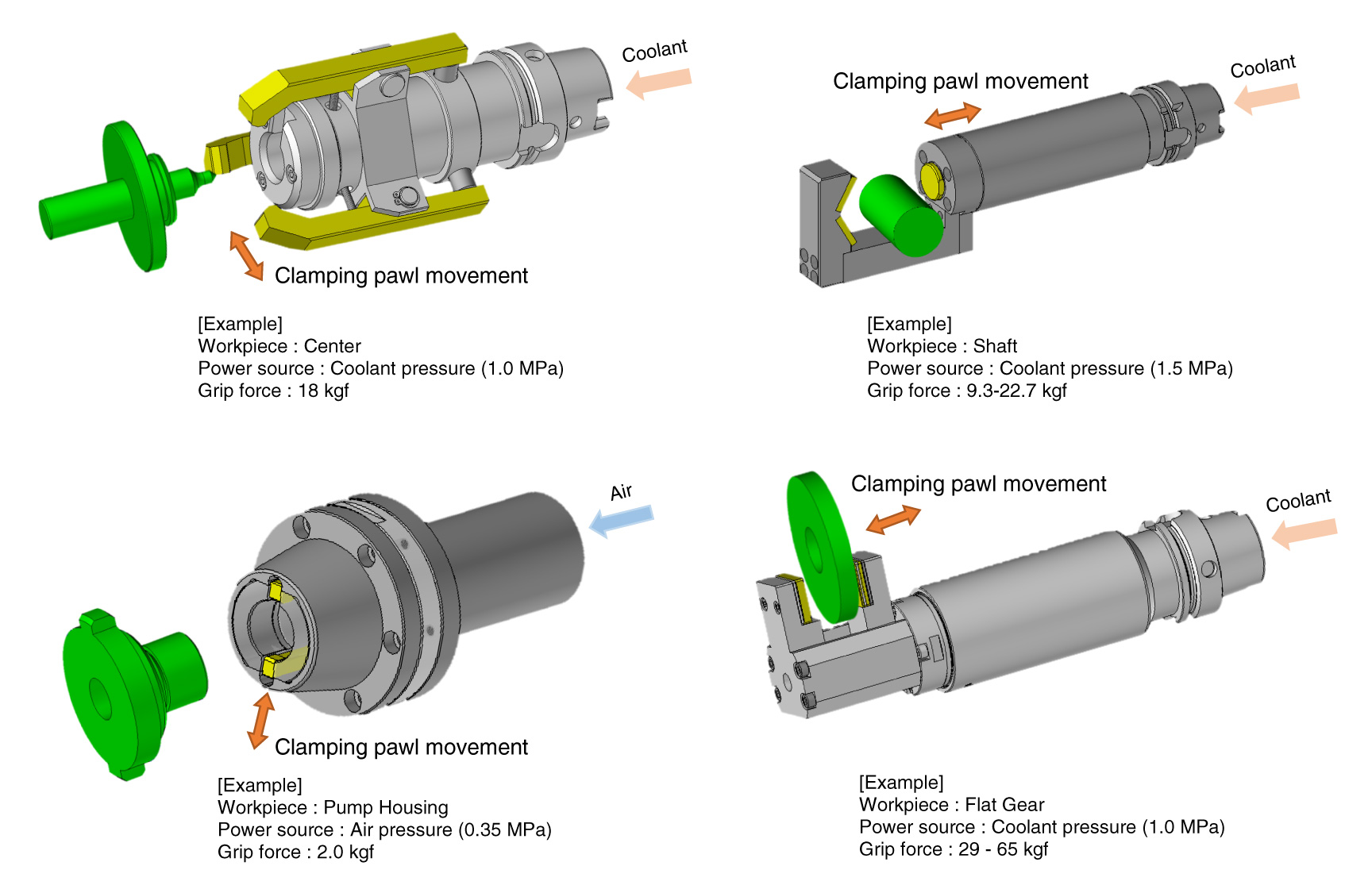

Various clamping methods are available according to the shape of the workpiece or the jig.

→“Automation”

→“Cost reduction”

→“Efficiency Improvement”

How to utilize Material-Handling

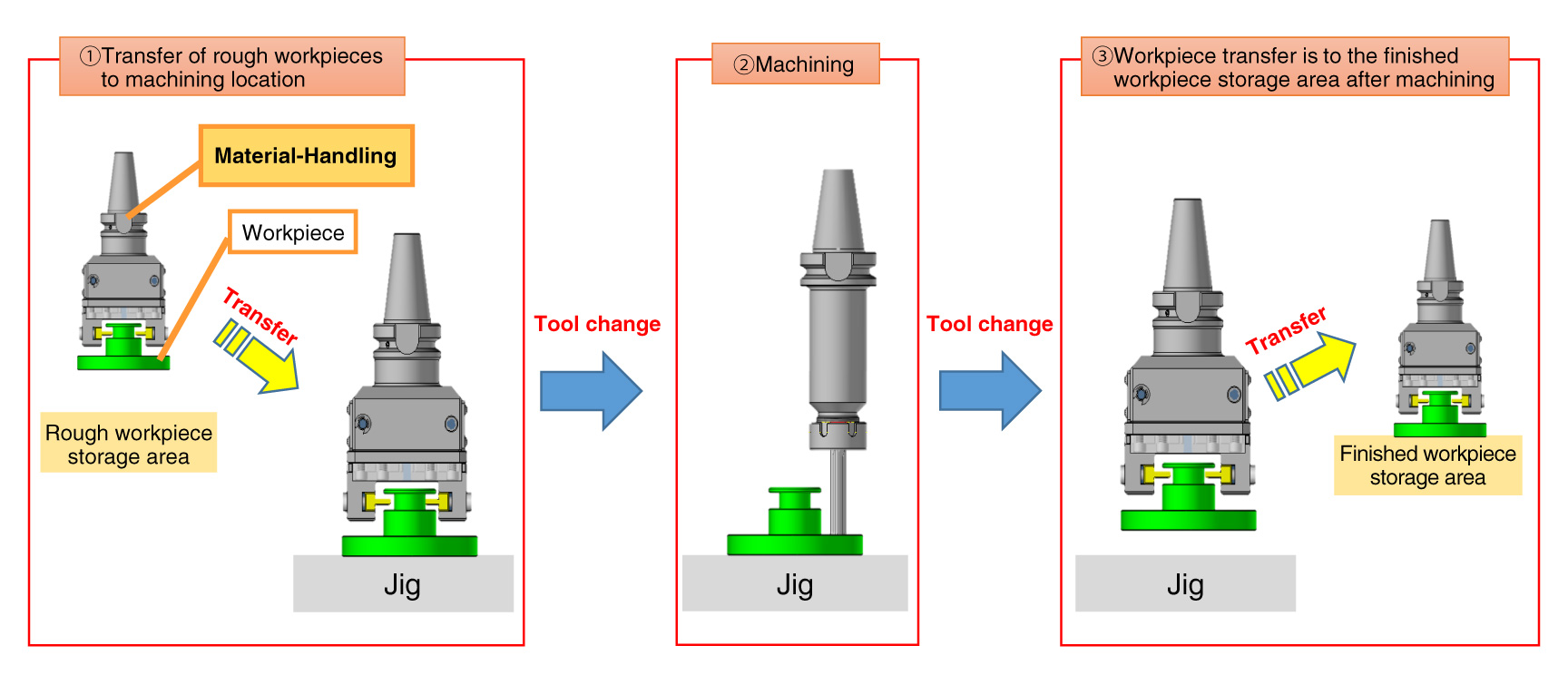

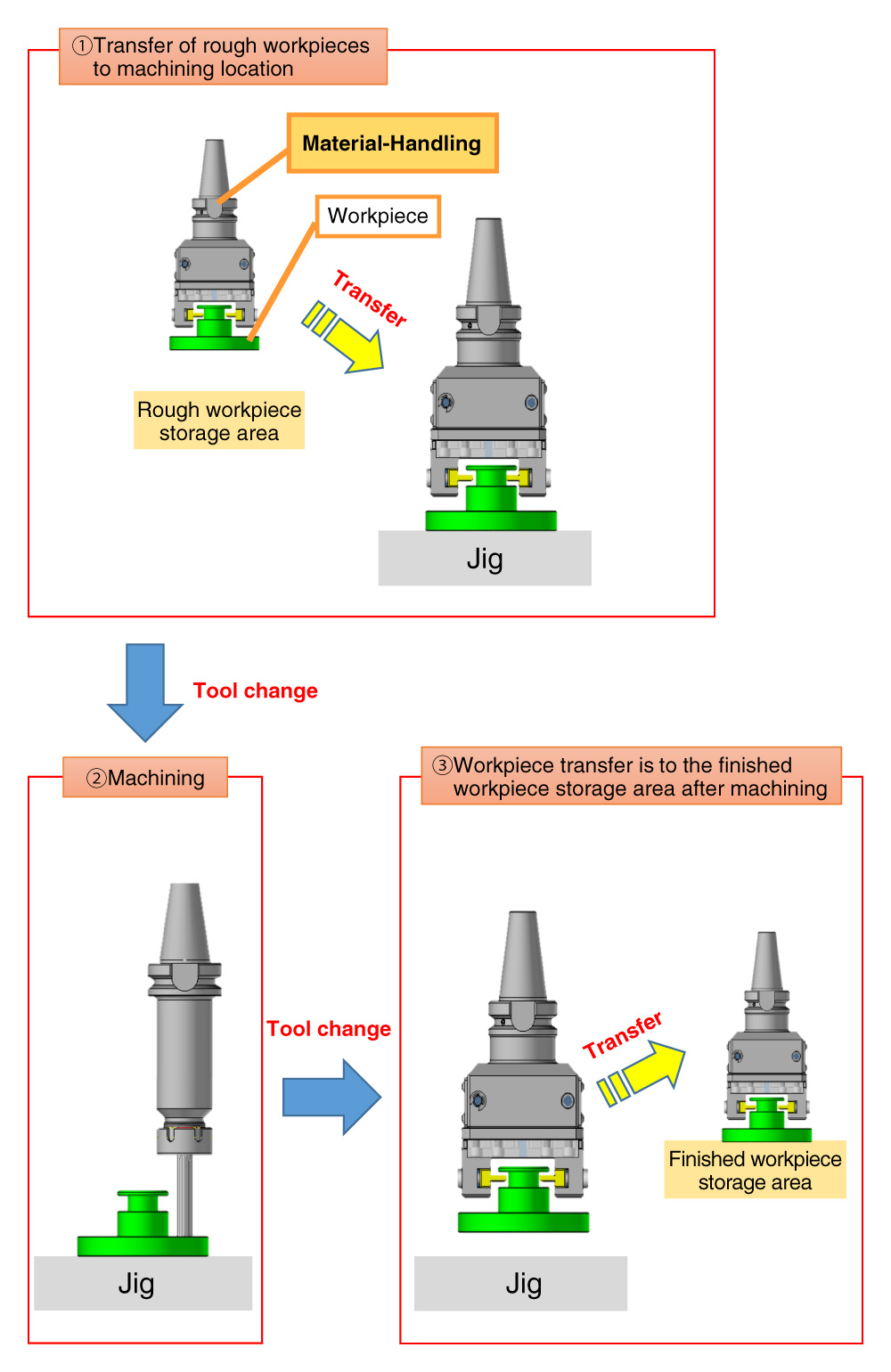

(Case 1) transfer of rough and finished workpieces

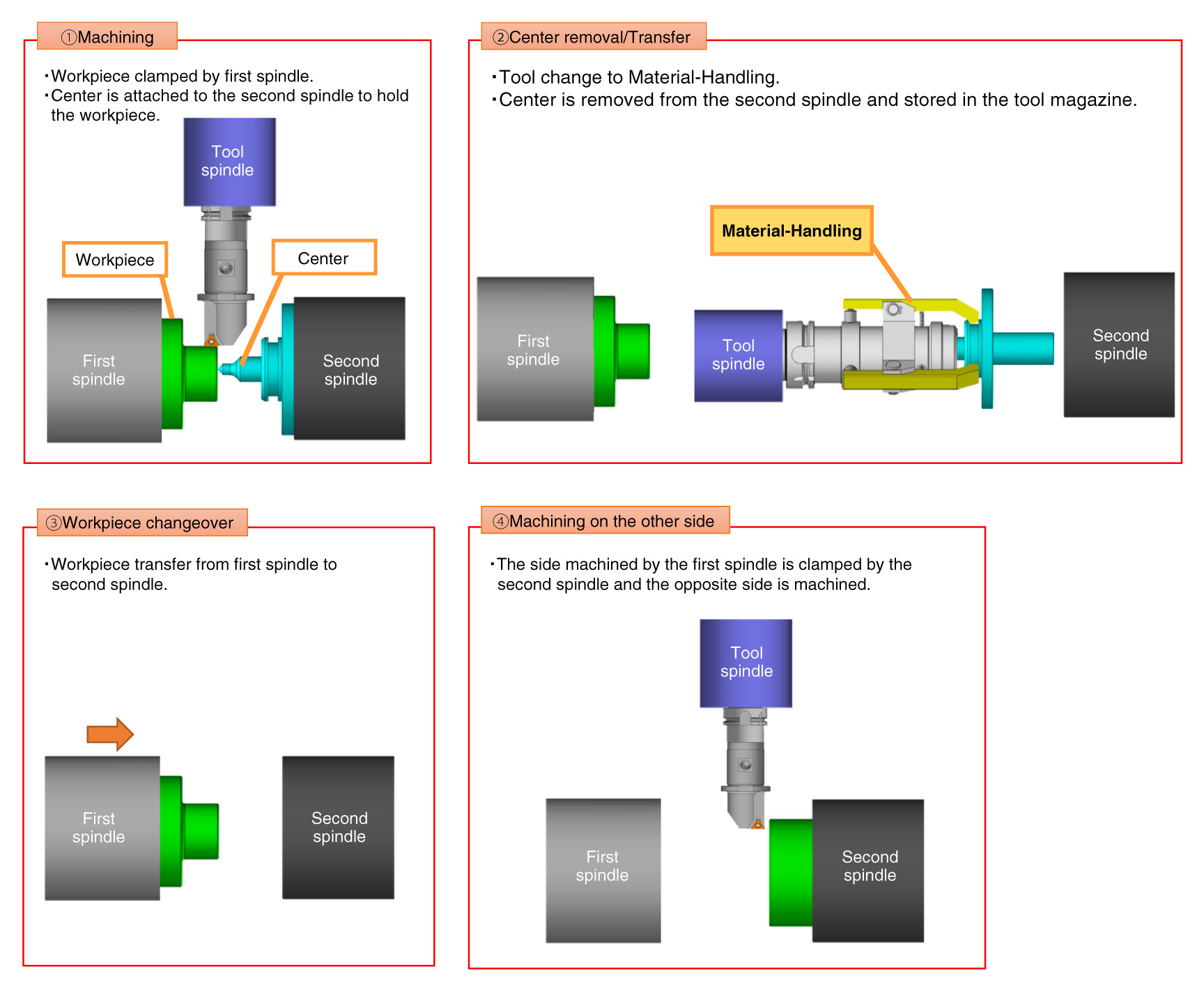

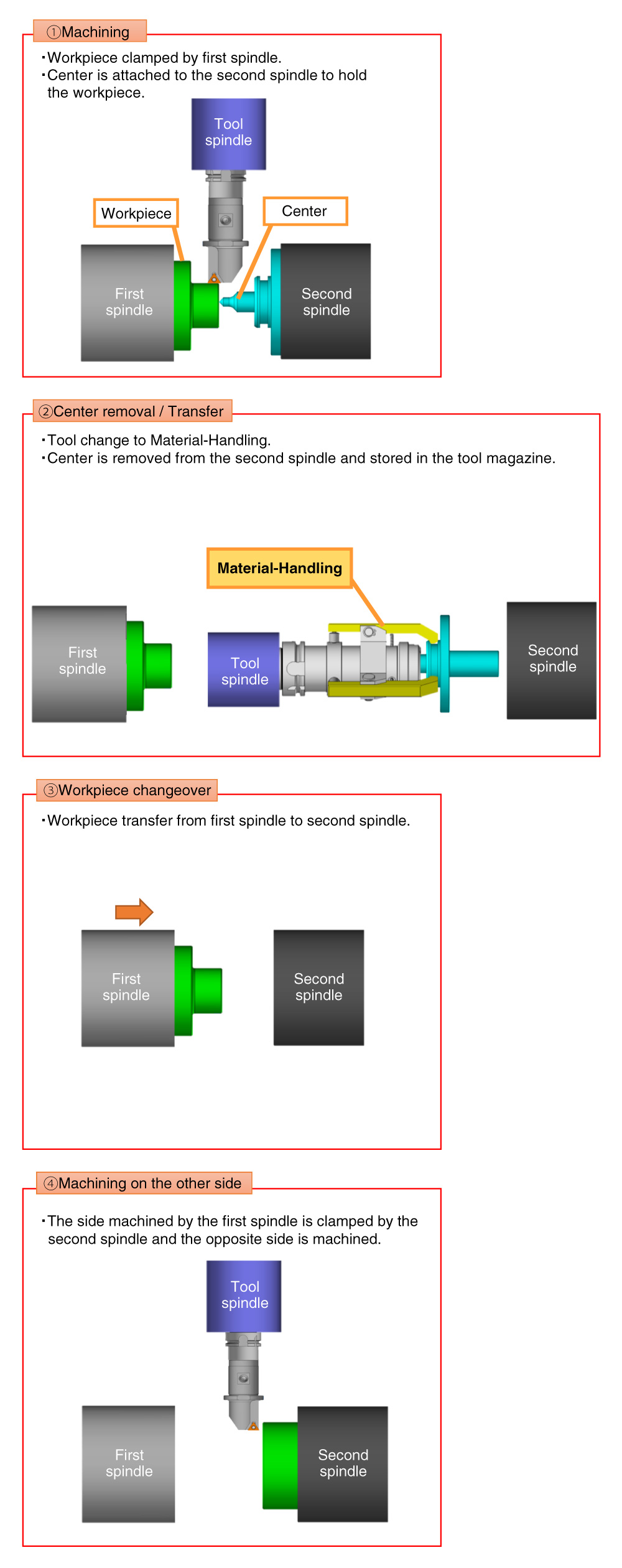

(Case 2) Workpiece changeover on a 5-axis lathe machine

Background / Point for Development

Background

- Conventionally, jig changeover and workpiece mounting and transport are performed either by robots or manually.

- However, robots are usually expensive, the manual labor is time-consuming and thus less efficient, due to the frequent operational stops (interruptions).

Point for Development

- The “Material Handling Series” utilizes three types of power sources (coolant pressure, air, and spindle rotation) enabling workpiece transfer and jig changeover in the same equipment (i.e. M/C).

It realizes both “automation” and “investment reduction” as well as the operational efficiency.

Product Specification

Examples of O.D. gripping series

Examples of I.D. Gripping Series