PARAPARA DrillPAT.P

A Solution to the chipping problem!

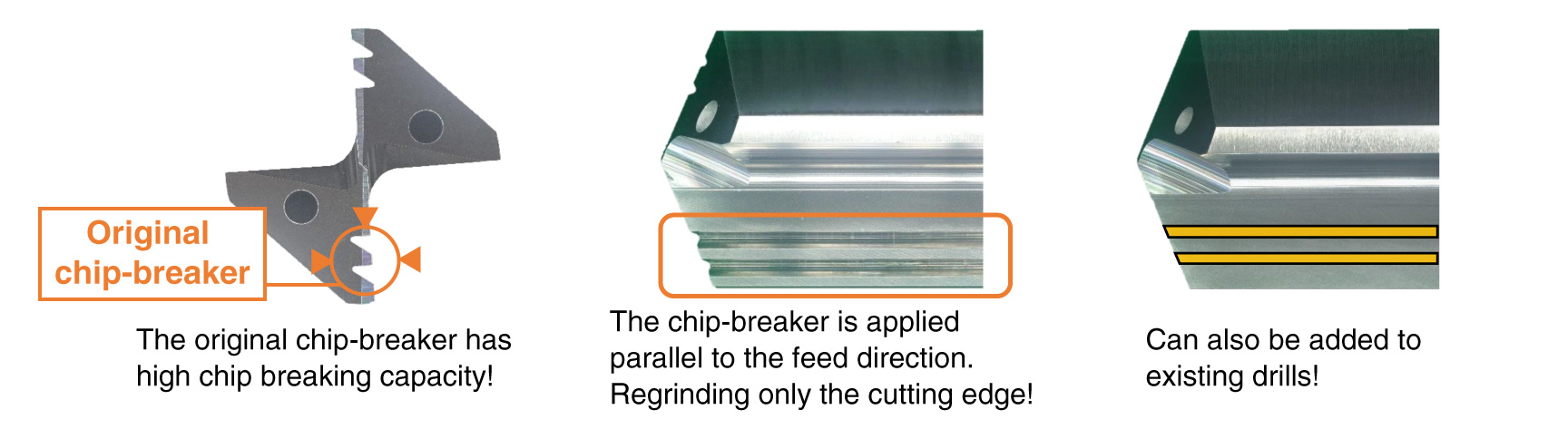

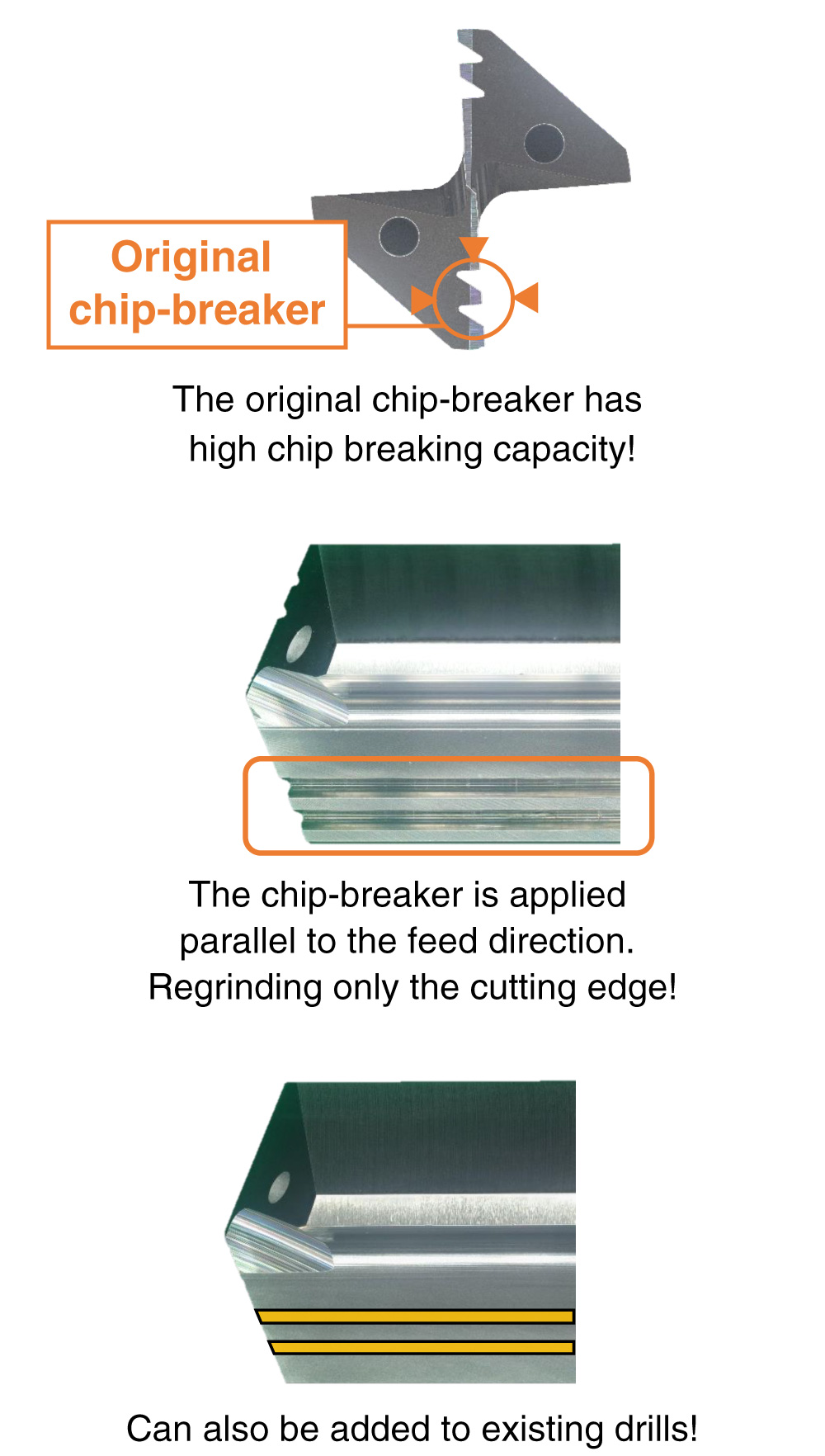

- Original breaker for chip separation!

Versatile drills with breaker

- High chip breaking capacity

- Eliminates chip entanglement and residues

- No need to rebuild breakers when regrinding

![]()

“Amazing Ideas / Facts!”

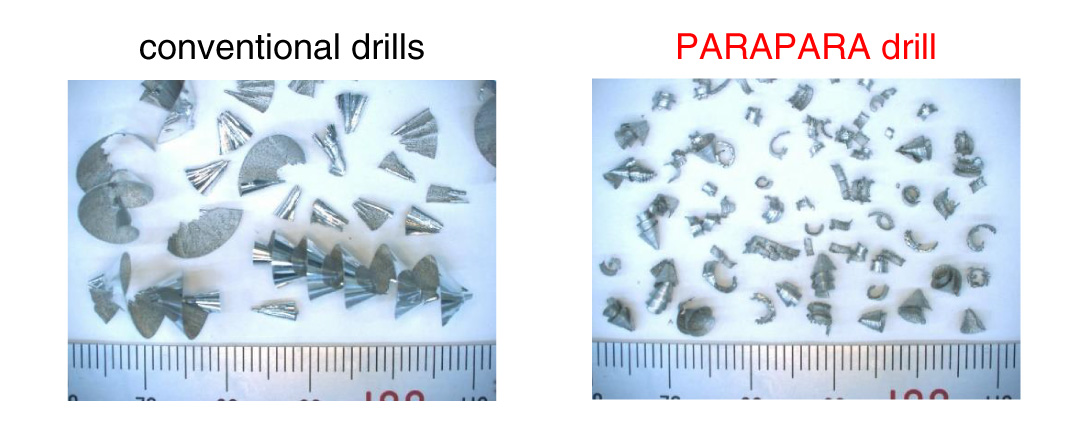

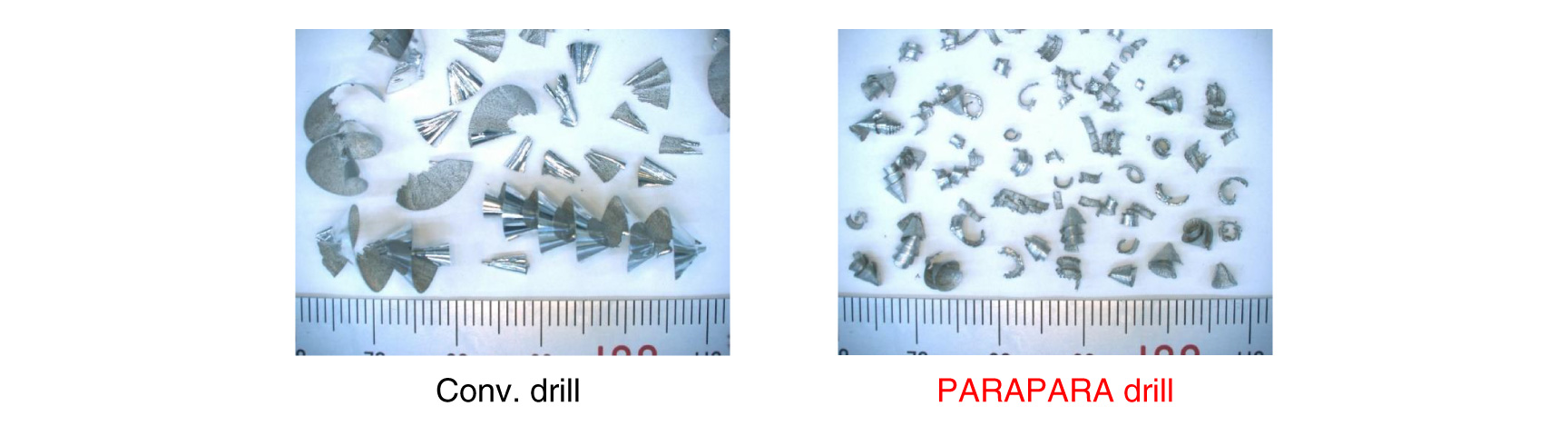

The Parapara Drill has an original shape of breaker on the flute, resulting in a high chip breaking capacity and eliminating the problems of chip entrapment and residues.

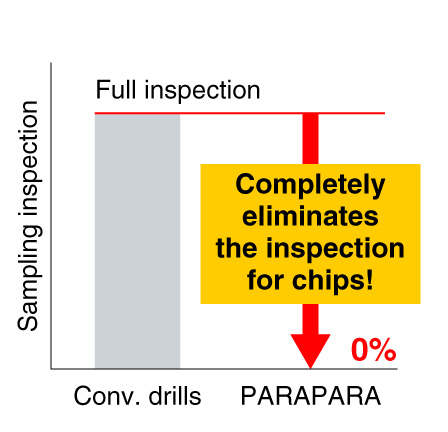

Contributes to the elimination of post inspection processes.

No need to re-add the breaker and thus can easily be reground.

Chip shapeGood !

Elimination of inspection process.

POINT!

high chip breaking capacity with the original breaker shapeExcellent !

Background / Point for Development

Background

- Problems such as chips winding around, remaining on the workpiece/jig and accumulating on the fixture occur during the drilling process.

Regular cleaning and additional inspection processes are required. - Conventional drills with nicks or breakers do not have sufficient chip breaking ability, and the breaker shape needs to be recreated for regrinding, which poses issues in “versatility”, “chip breaking ability”, and “regrinding”.

Point for Development

- The PARAPARA Drills solved these problems by adopting an original shape of breaker and developed a drill with both ‘high chip breaking capacity’ and ‘ease of regrinding’.

Example

| Tool | Parapara drill |

|---|---|

| Workpiece | Cylinder head |

| Material | AC2C-T6 |

| Tool Diameter | ø25mm |

| Cutting Conditions |

|

Chip comparison

Product Specification

Parapara drill

Tool Specification

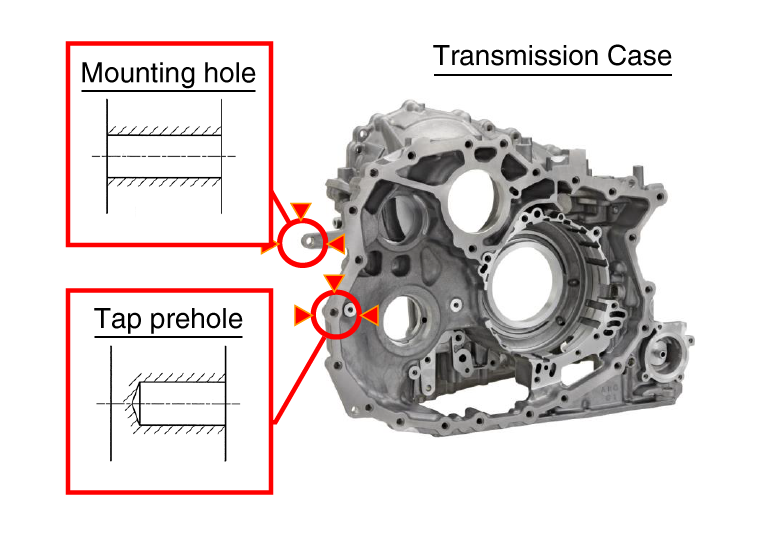

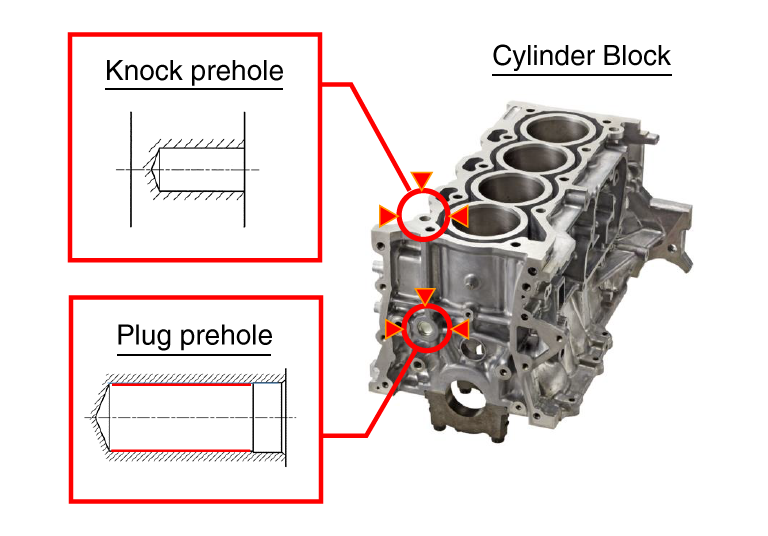

| Process covered | Tap prehole, Knock prehole, aluminum general hole |

|---|---|

| Diameter | ø8 - 26 |

| Standard conditions |

|

| Performance | IT9 |

Example of applicable work