Plunge V/F

Achieving both Slim profile and

high precision machining!

- Compact clamp structure ensures high proximity and achieves high-precision valve seat machining.

- High precision machining is made possible by minimum reamer projection and runout adjustment.

![]()

“Amazing Ideas / Facts!”

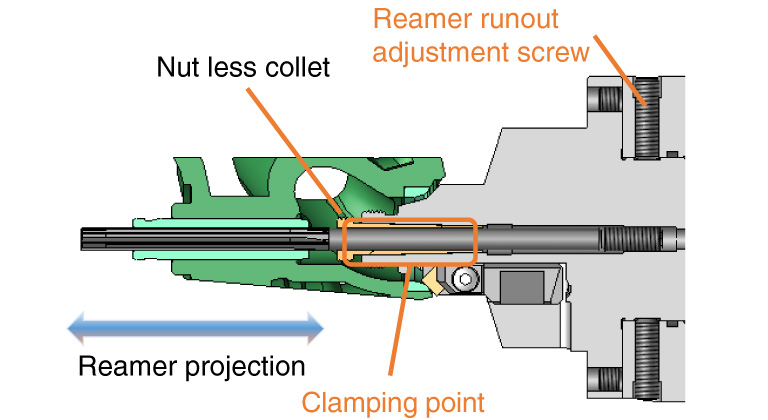

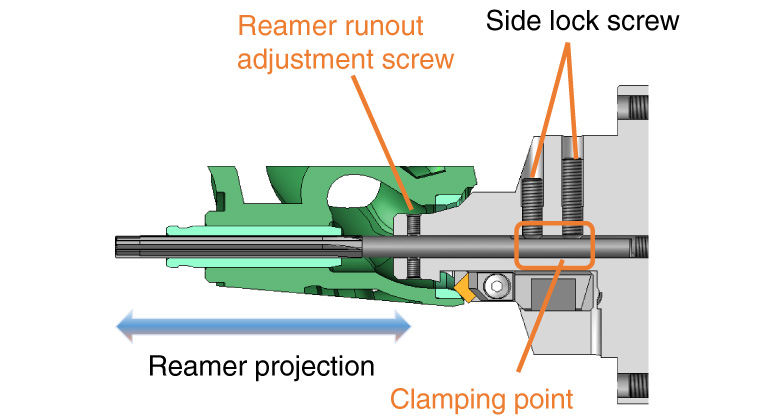

Plunge-cut valve finishers are available in two types of reamer holding mechanisms: “NLC (Nut Less Collet)” and “Side Lock”.

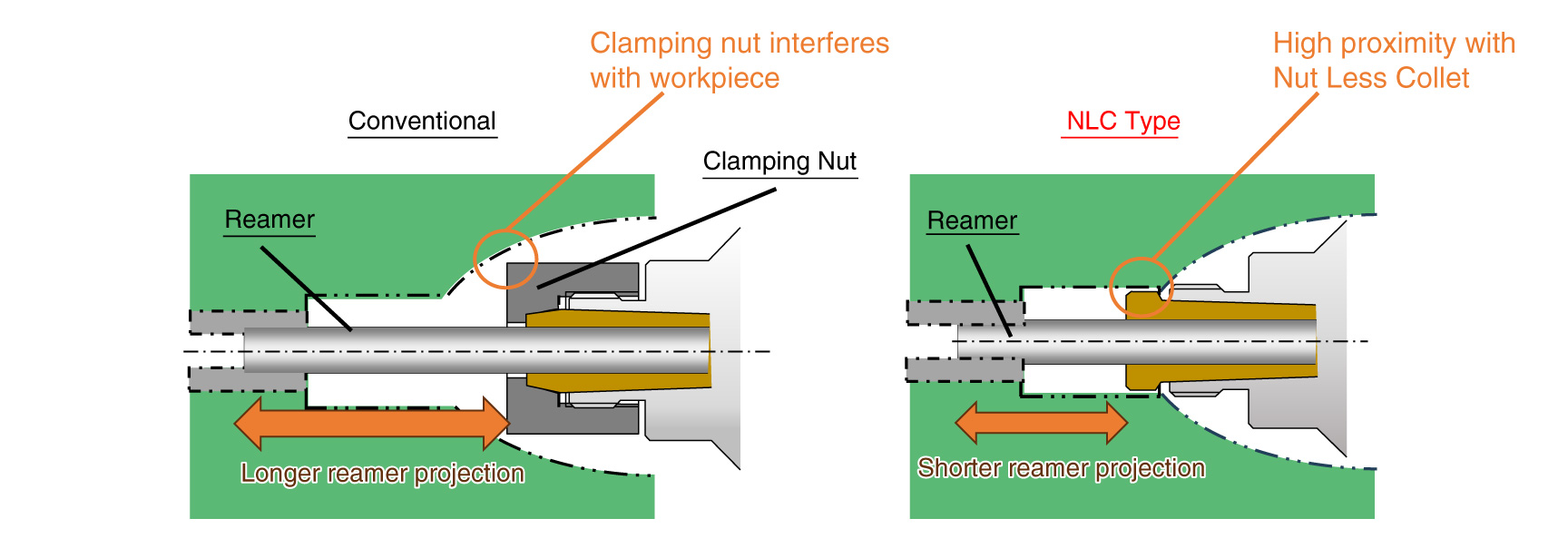

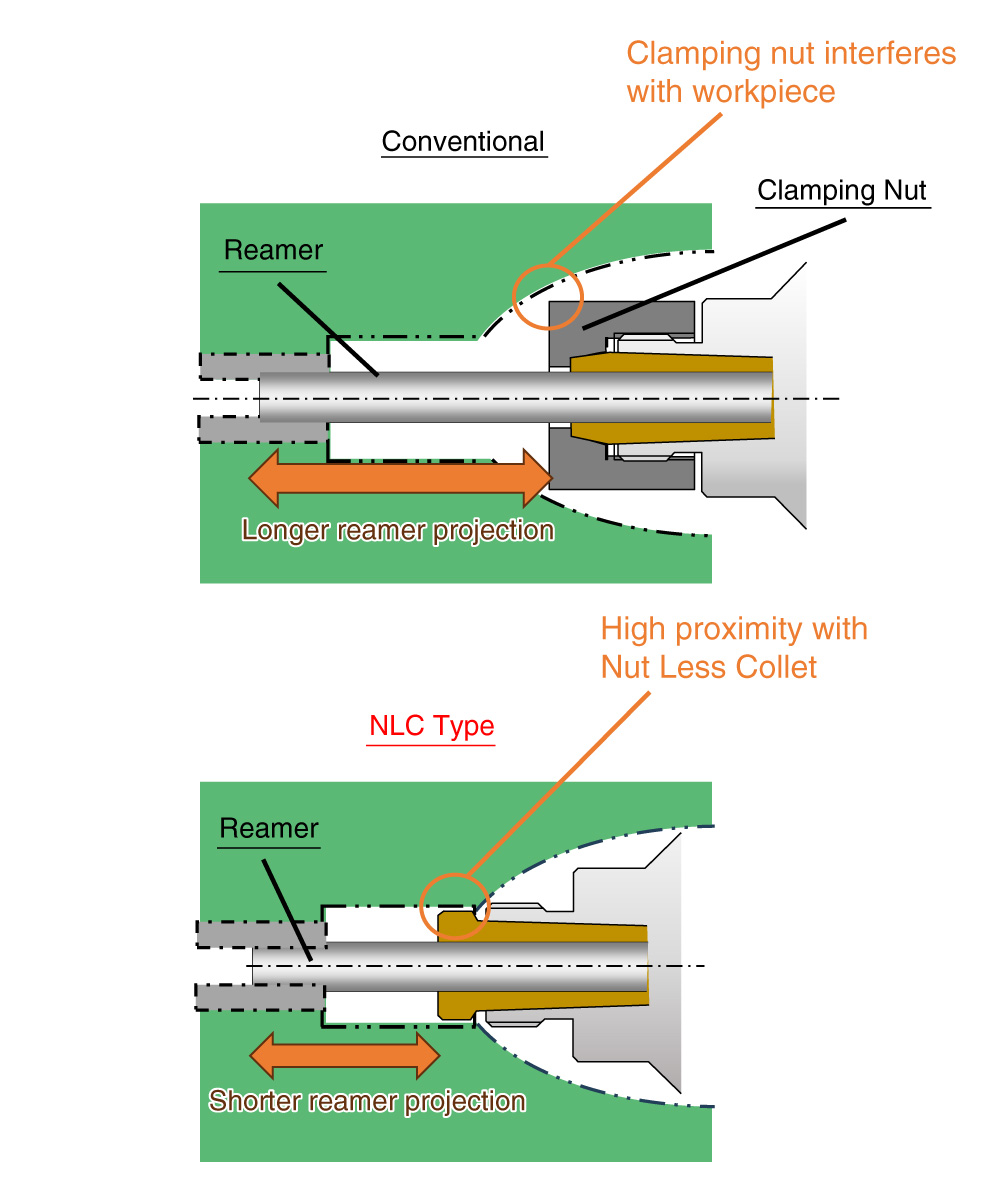

The NLC type eliminates the clamp nut required for a conventional collet chuck, thereby slimming down the holder body and avoiding interference with the workpiece, making it possible to minimize the amount of reamer projection with high proximity to the workpiece.

The reamer's runout can also be adjusted to obtain stable precision machining of the valve guide hole.

Reamer Holding MechanismGood !

| NLC Type | Side Lock Type | |

|---|---|---|

| Structure |  |

|

| Reamer runout accuracy | ◎ | ◎ |

| Reamer projection | ◎ | ○ |

| Operability | ○ | ○ |

| Price | ○ | ◎ |

POINT!

NLC Type: Minimum reamer projectionExcellent !

POINT!

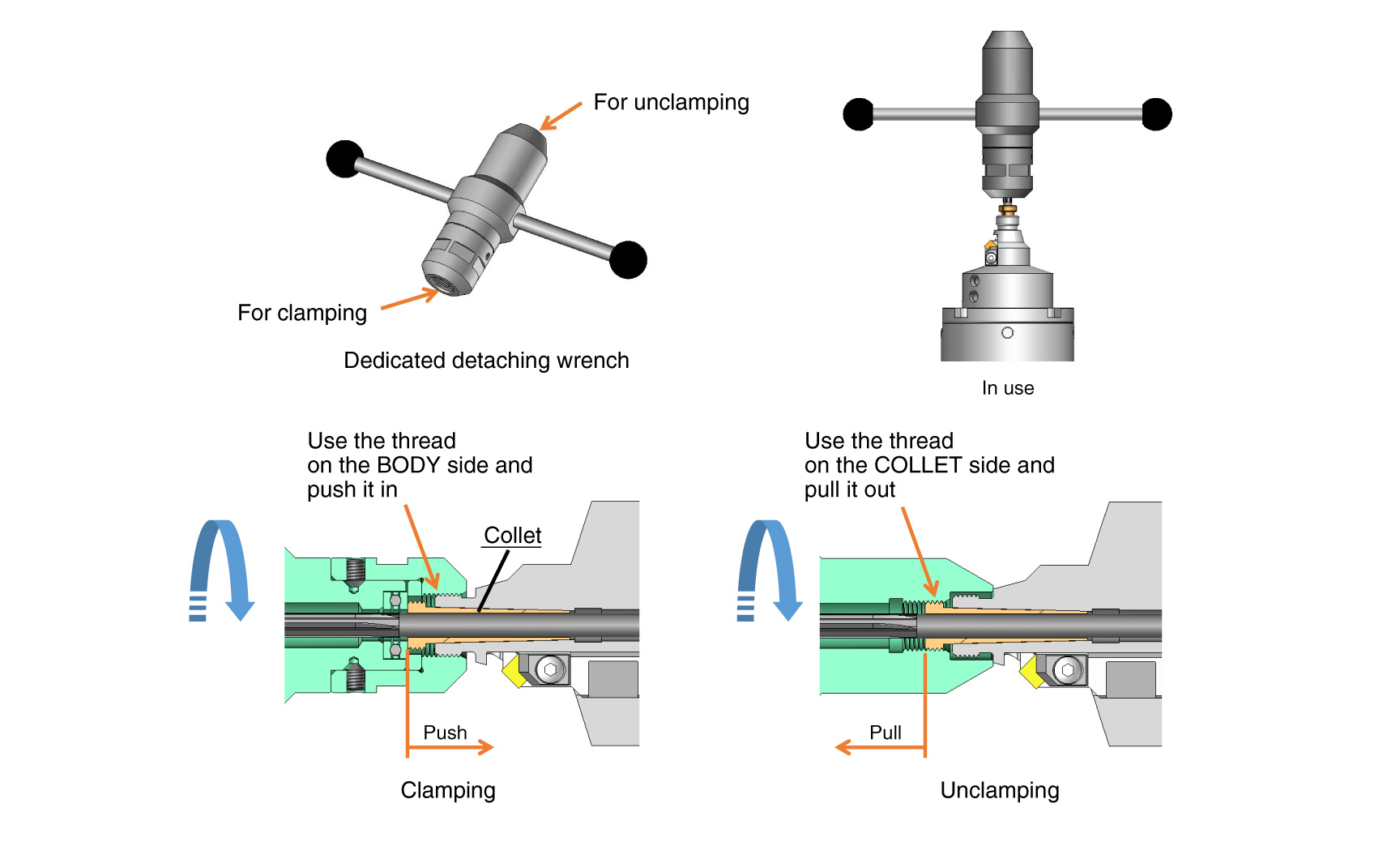

NLC Type: Special collet detaching methodExcellent !

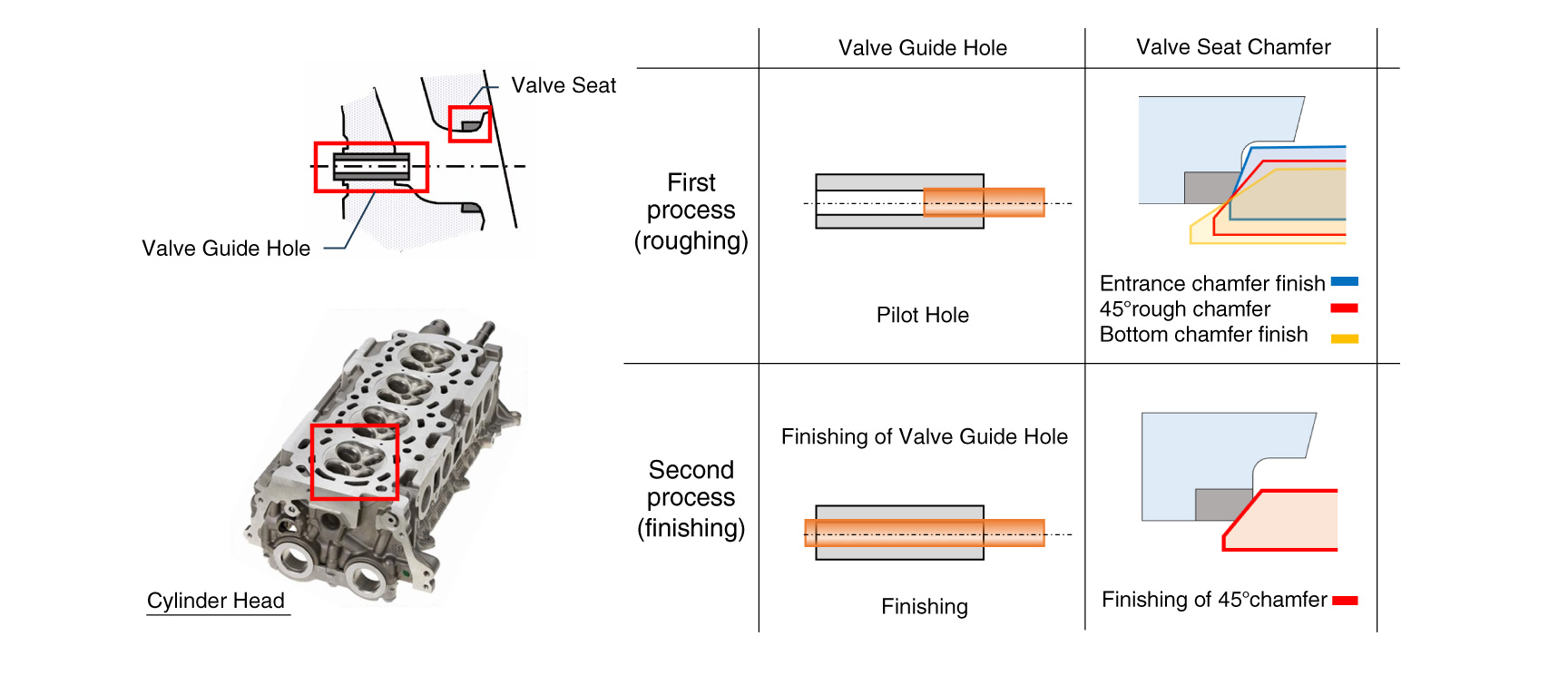

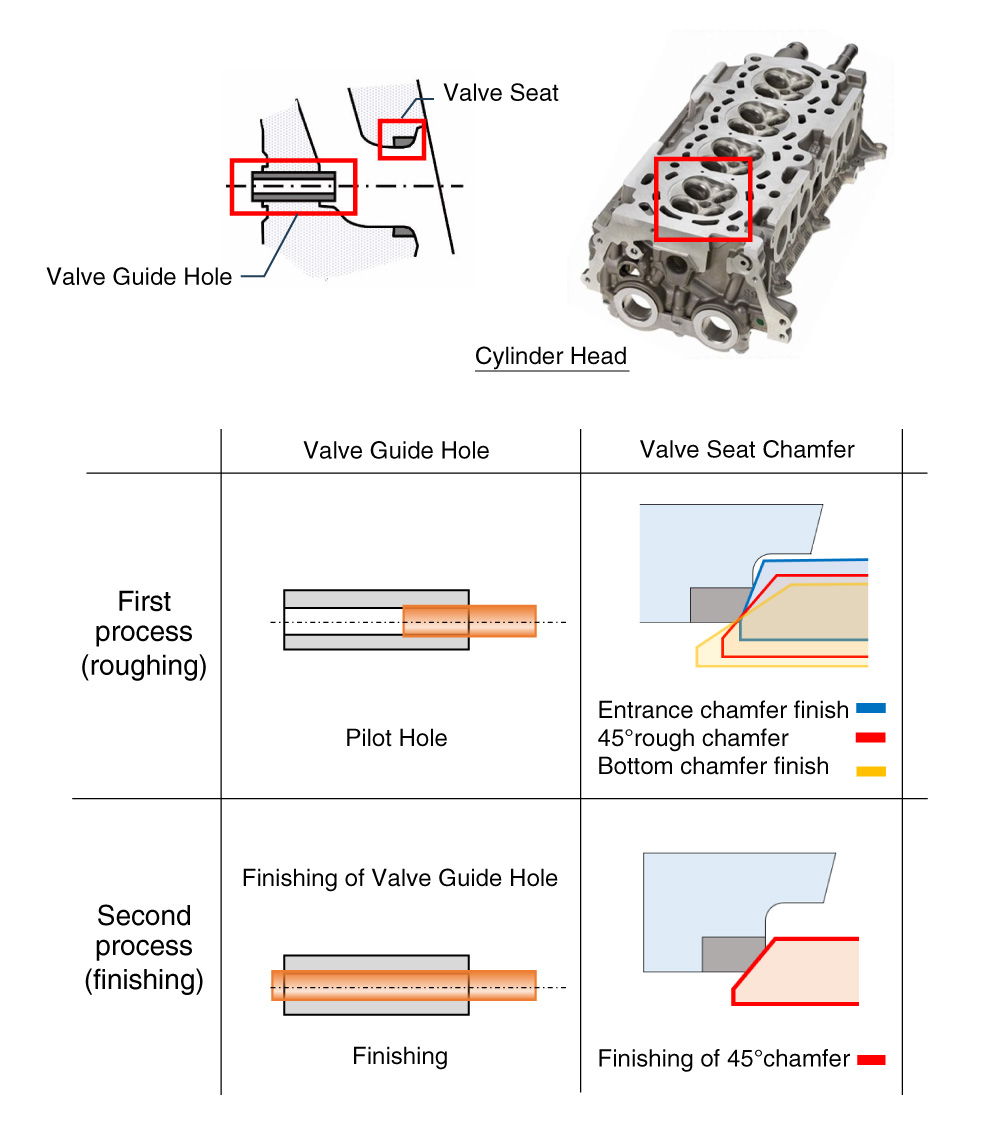

Machining Process

First process: Valve pilot hole + Valve seat entrance chamfering

Second process: Finishing of Valve guide hole + Valve seat 45° chamfer

Background / Point for Development

Background

- The machining of valve seat surfaces and valve guide holes requires high accuracy. But the shift from Traverse (on dedicated machines) to Plunge (general M/C) for the purpose of investment cut often generated a problem of less & unstable accuracy.

Point for Development

- The NLC Type eliminates the clamping nut on the reamer.

- The Side-Lock Type has a compact reamer blade runout adjustment mechanism and a slimmer holder.

- This avoids interference with the workpiece and realizes the shortest reamer protrusion.

- The side-lock type enables stable plunge-type machining with high-precision and thus investment reduction.

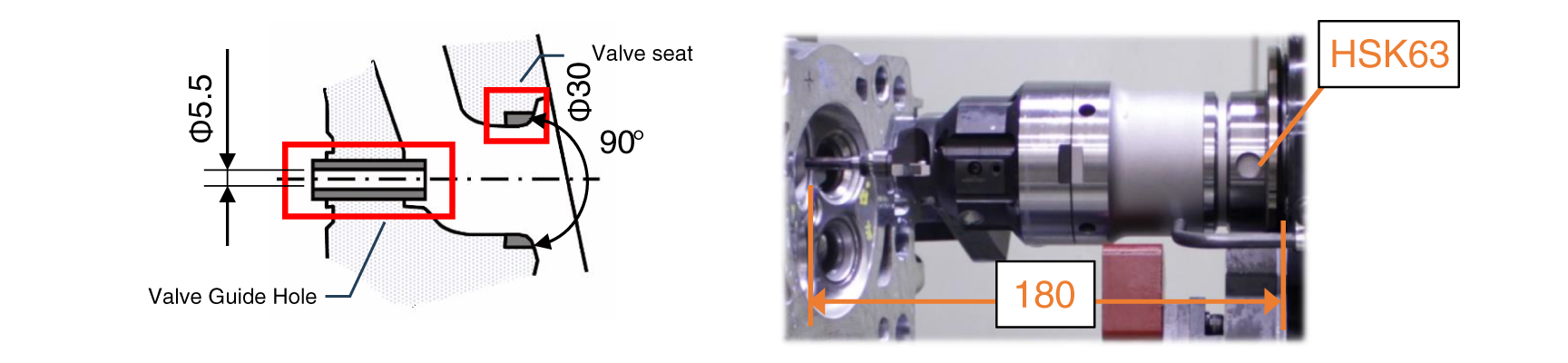

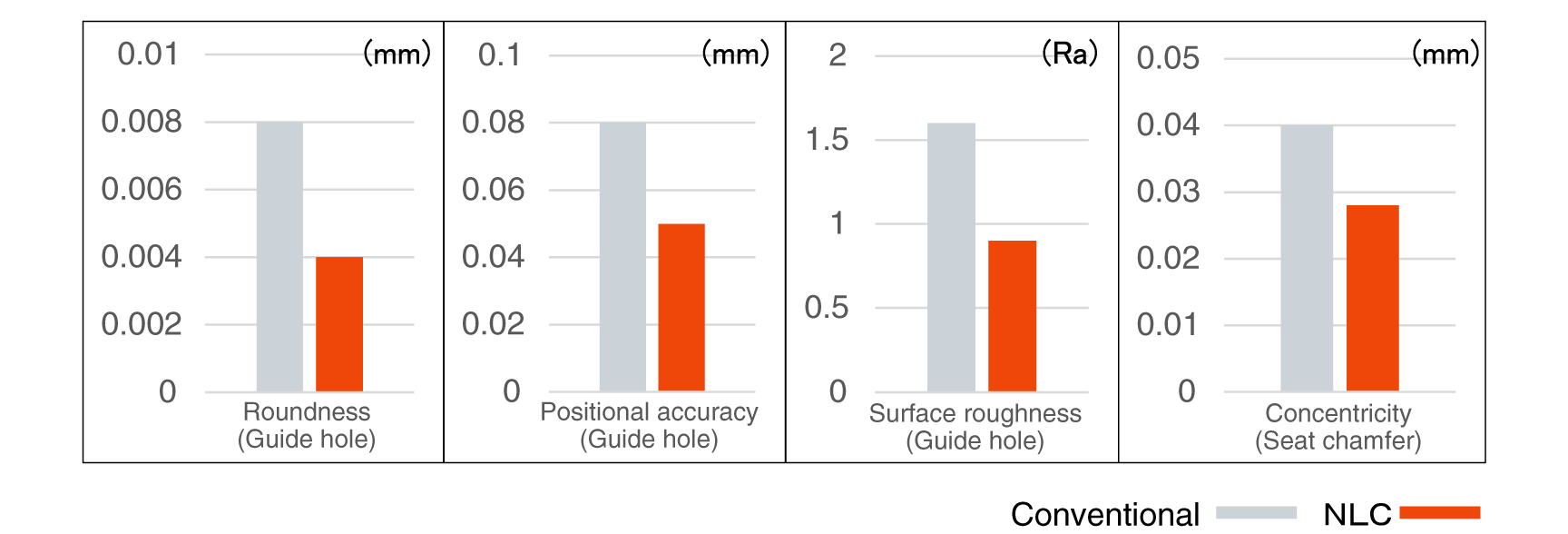

ExampleNLC Type

| Workpiece | Cylinder Head Valve Guide Hole | Cylinder Head Valve Seat | |

|---|---|---|---|

| Material | Sintered metal | Sintered metal | |

| Tool | Carbide reamer | Carbide bite | |

| Cutting Conditions |

Roughing | Rotational speed: N=4600min-1 Cutting speed: V=80m/min Cutting feed: f=0.3mm/rev |

Rotational speed: N=1600min-1 Cutting speed: V=150m/min Cutting feed: f=0.13mm/rev |

| Finishing | Rotational speed: N=4600min-1 Cutting speed: V=80m/min Cutting feed: f=0.3mm/rev |

Rotational speed: N=1600min-1 Cutting speed: V=150m/min Cutting feed: f=0.1mm/rev |

|

| Coolant | Coolant hole | Coolant hole | |

| Tooling |  |

||

| Processing accuracy |  |

||