QT Tool Quarter Turn Adjustment Tool

Automatic diameter adjustment

on general-purpose machines

- Tools designed for high-precision machining and precise diameter compensation

- Simple compensation enables investment reduction

- Automatic adjustment without dedicated equipment

- Micro adjustment (ø2.5µm) is possible

“Amazing Ideas / Facts!”

The QT tool utilizes the functions of a general purpose machining center to achieve automatic compensation.

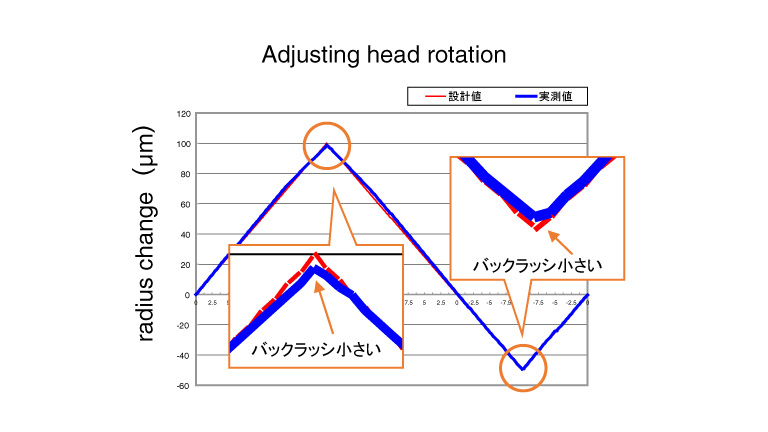

A unique mechanism that enables high-precision fine-tuning in ø2.5µm increments, therefore, ‘High productivity’, ‘high-precision machining’ and ‘reduced capital investment’.

POINT!

Automatic correction simply by introducing QT tools and simple fixtures on general-purpose machinesExcellent !

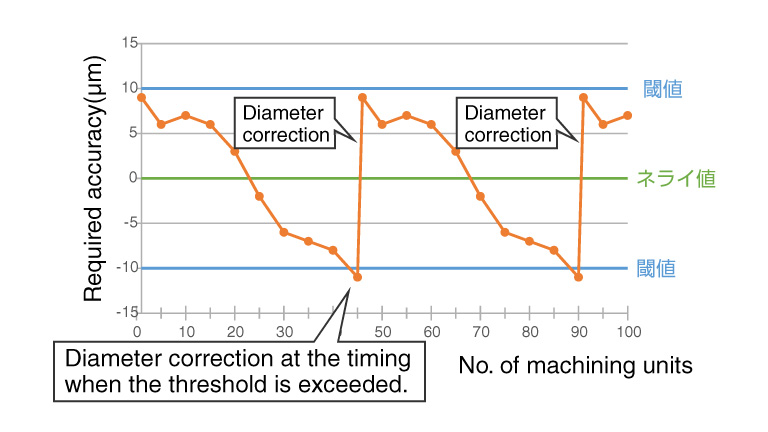

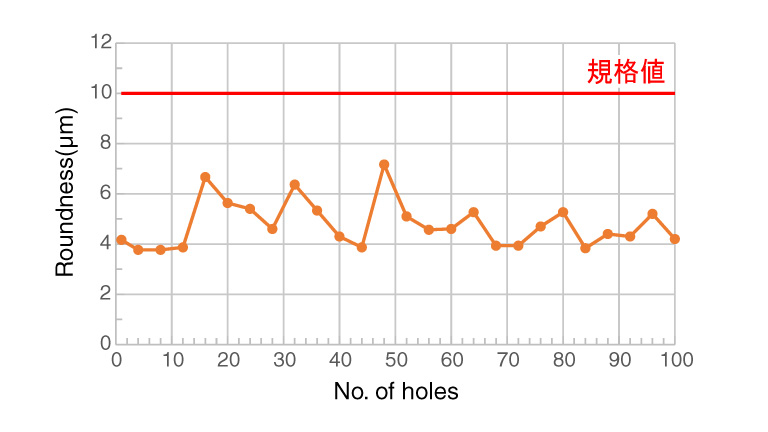

High-precision correction and excellent trackingGood !

- Separability ø2.5µm

- Excellent tracking

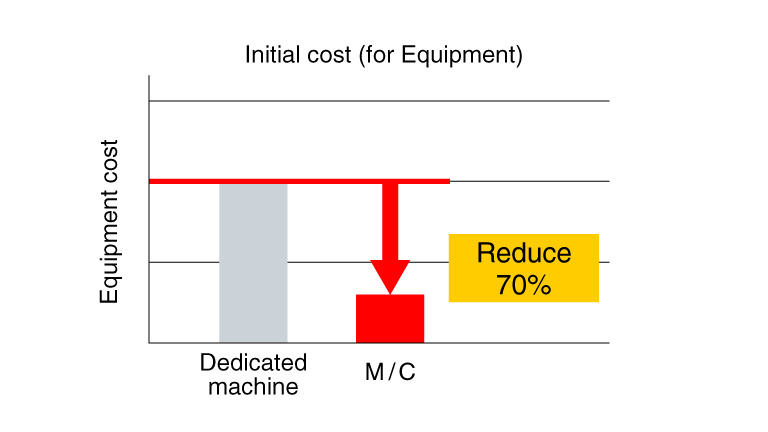

Reduction of equipment installation costsGood !

- Use of machining centres reduces equipment costs by 70%

Background / Point for Development

Background

- In the case of machining difficult-to-machine materials and long cutting distances, the cutting-edge wear progresses quickly, leading to more frequent dimensional adjustments of the cutting edge and insert replacement, which affects the operation of the production line.

- As a solution, automatic compensation of machining diameters using dedicated equipment is used, but this requires significant capital investment.

Point for Development

- QT tools utilize the functions of machining centres to achieve automatic compensation of diameters, enabling machining on general-purpose machines.

- This eliminates the need for special compensation equipment and facilities, reduces investment and improves the utilisation rate of the production line.

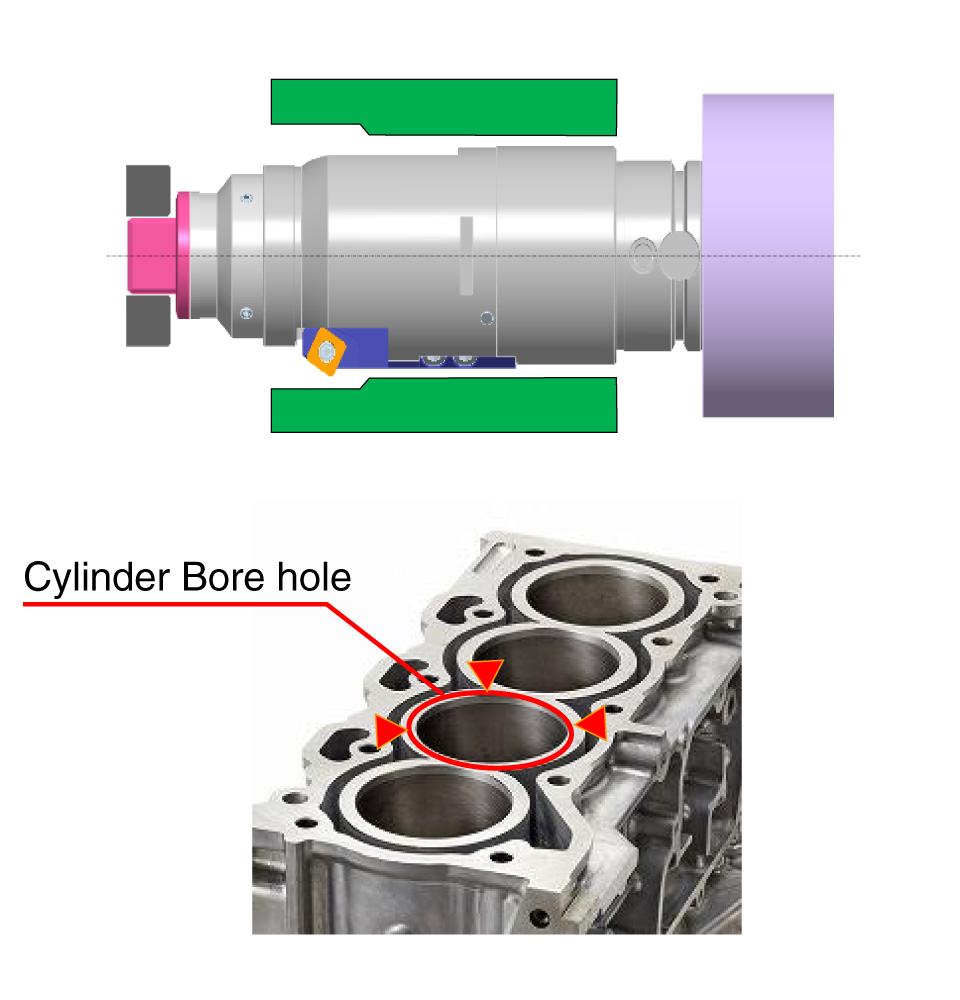

Example

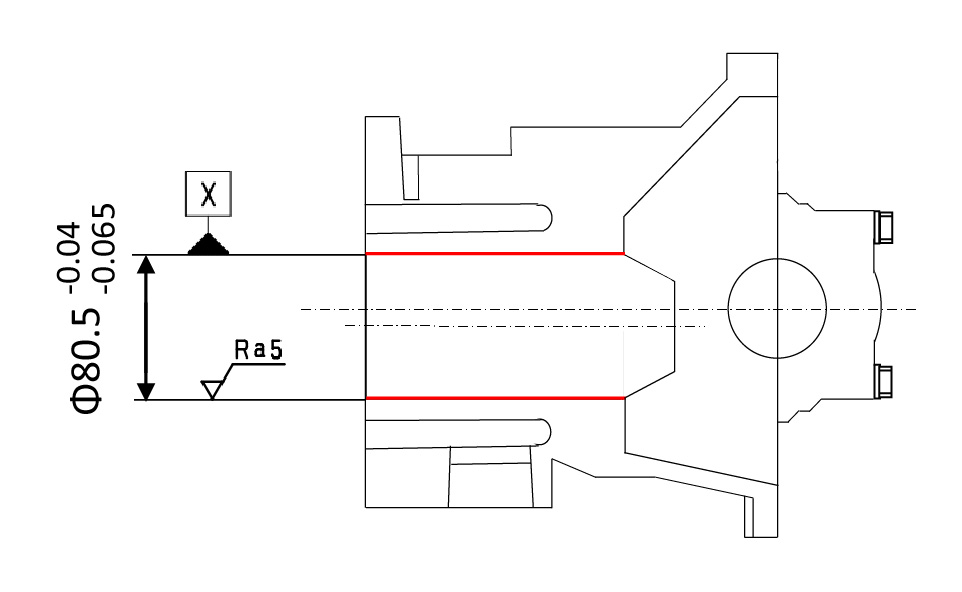

| Workpiece | Cylinder block, bore hole |

|---|---|

| Material | FC |

| Tool Diameter | ø80.5mm |

| Cutting Conditions |

|

| Number of machining units |

100 units |

| Required accuracy |  |

|---|

Required accuracy

Roundness

Product Specification

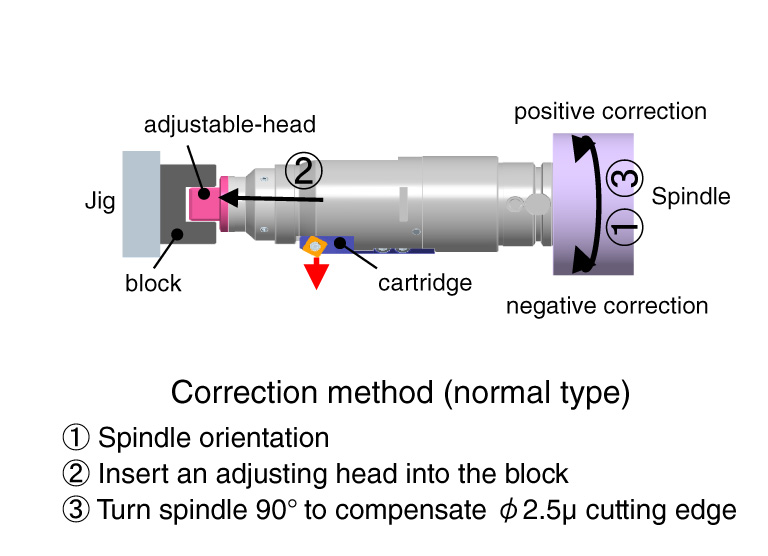

Normal type

Tool Specification

| Process covered |

Iron-based finishing boring (e.g. cylinder bore finishing, crank hole finishing, connecting rod large end bores, etc.) |

|---|---|

| Diameter | ø45 - (Only for through hole) |

| Standard conditions |

|

| Resolution | ø2.5µm per revolution |

| Compensation | +ø0.2 to -ø0.1 |

Example of applicable work

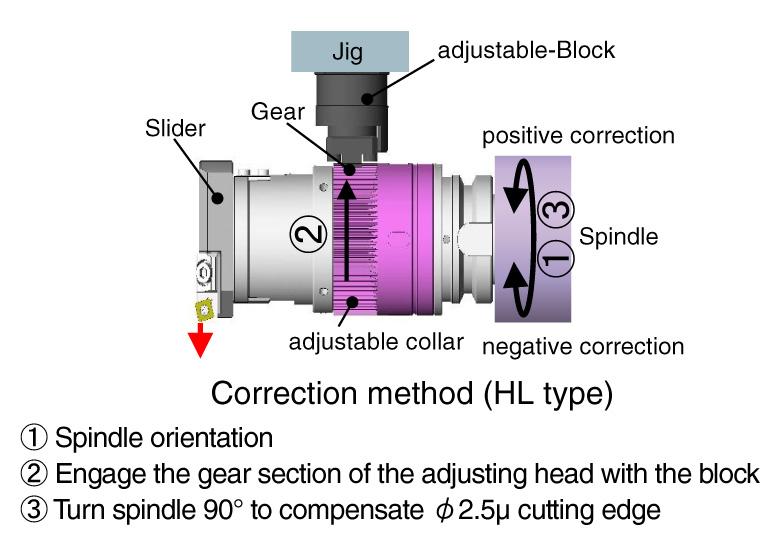

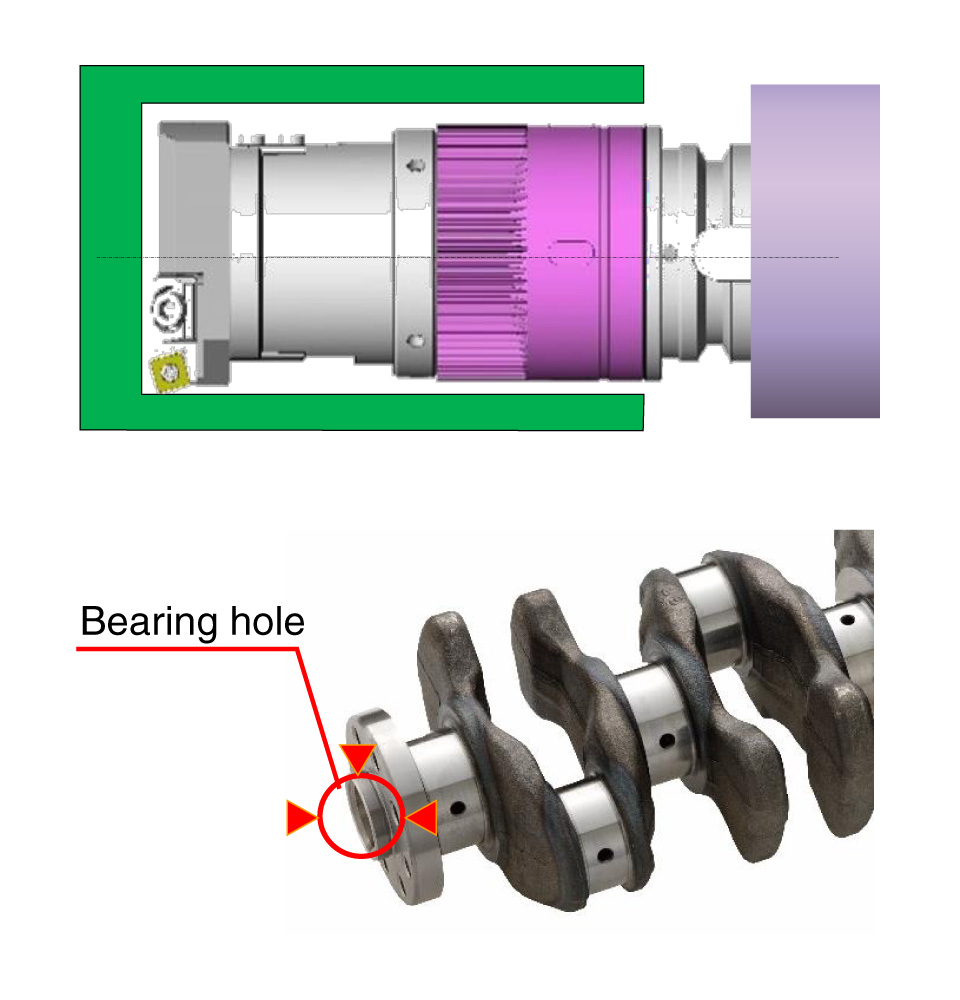

HL (Head less) Type

Tool Specification

| Process covered |

Iron-based finishing boring (e.g. crankshaft bearing holes) |

|---|---|

| Diameter | ø70 - (Only for stop hole) |

| Standard conditions |

|

| Resolution | ø2.5µm per revolution |

| Compensation | +ø0.2 - -ø0.1 |

Example of applicable work

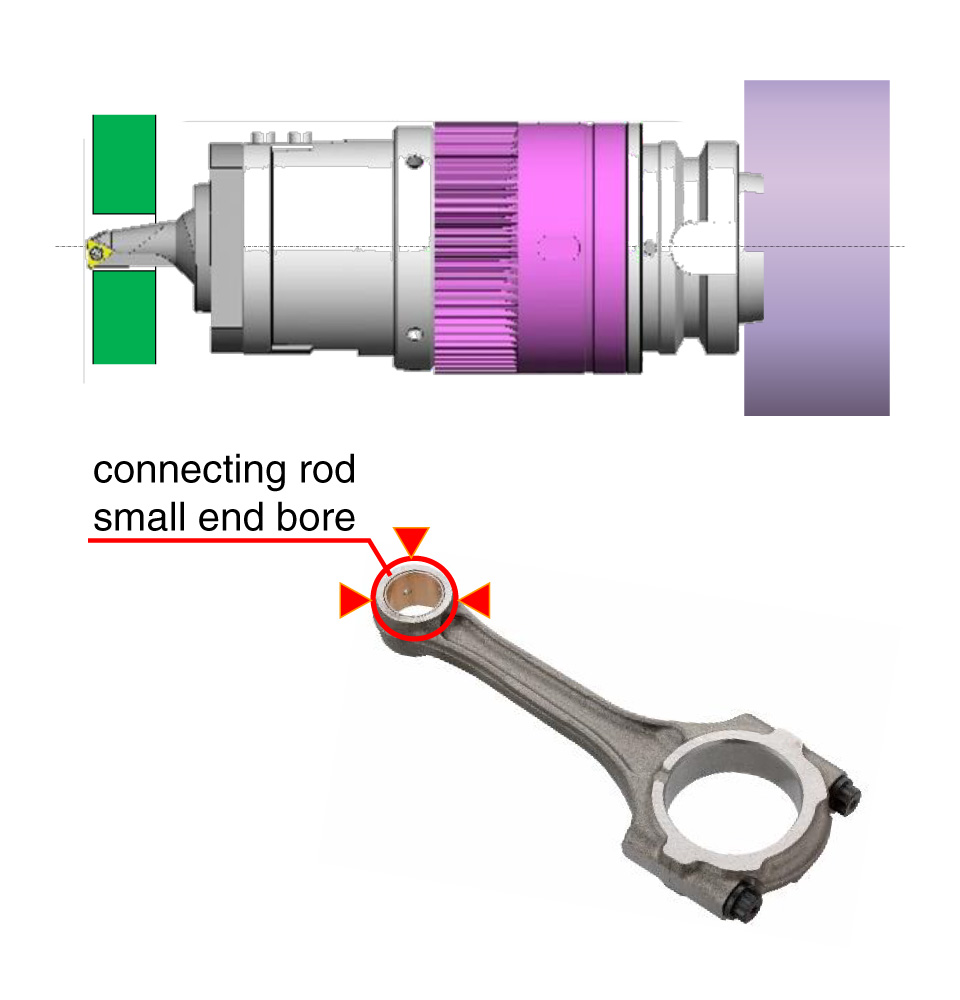

BB (Boring Bar) Type

Tool Specification

| Process covered |

Iron-based finishing boring (e.g. connecting rod small end bore, gear bore finishing, etc.) |

|---|---|

| Diameter | ø8 - (Only for small hole) |

| Standard conditions |

|

| Resolution | ø2.5µm per revolution |

| Compensation | +ø0.2 - -ø0.1 |

Example of applicable work