Shank-through GHI Reamer

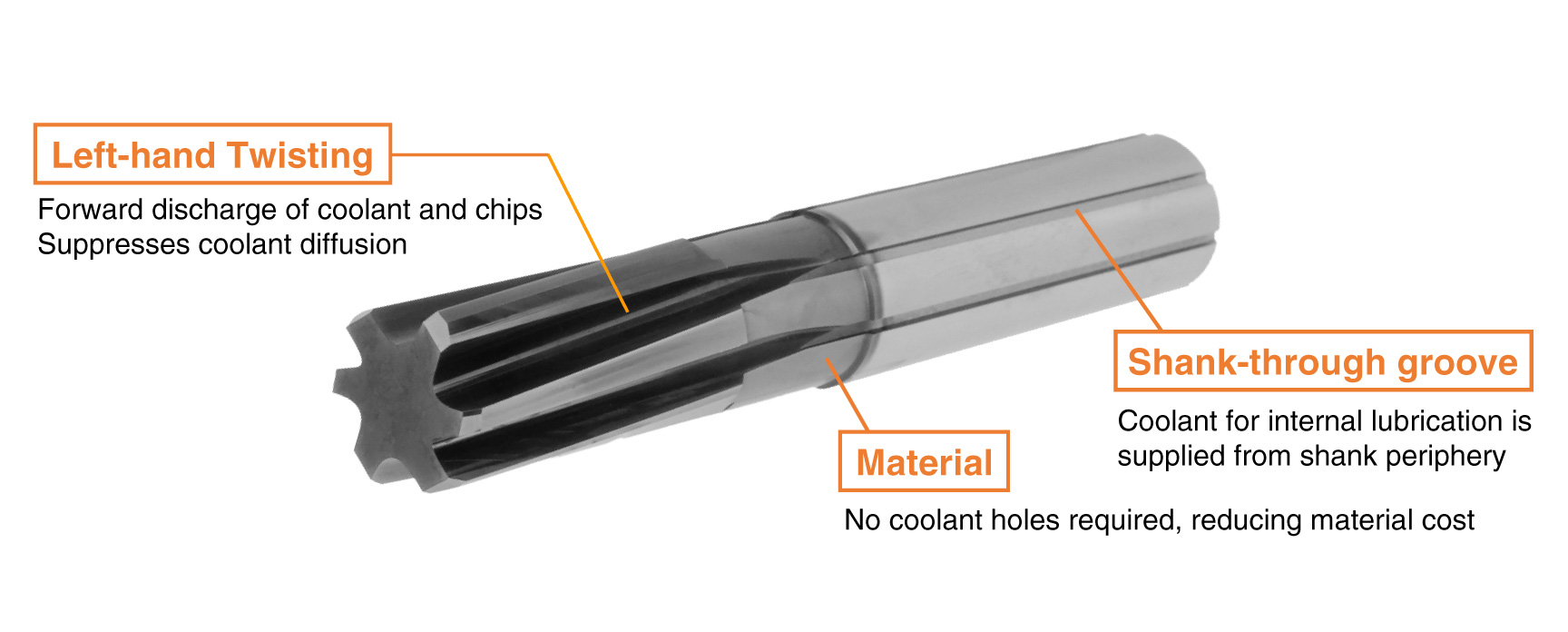

By supplying coolant from the shank,

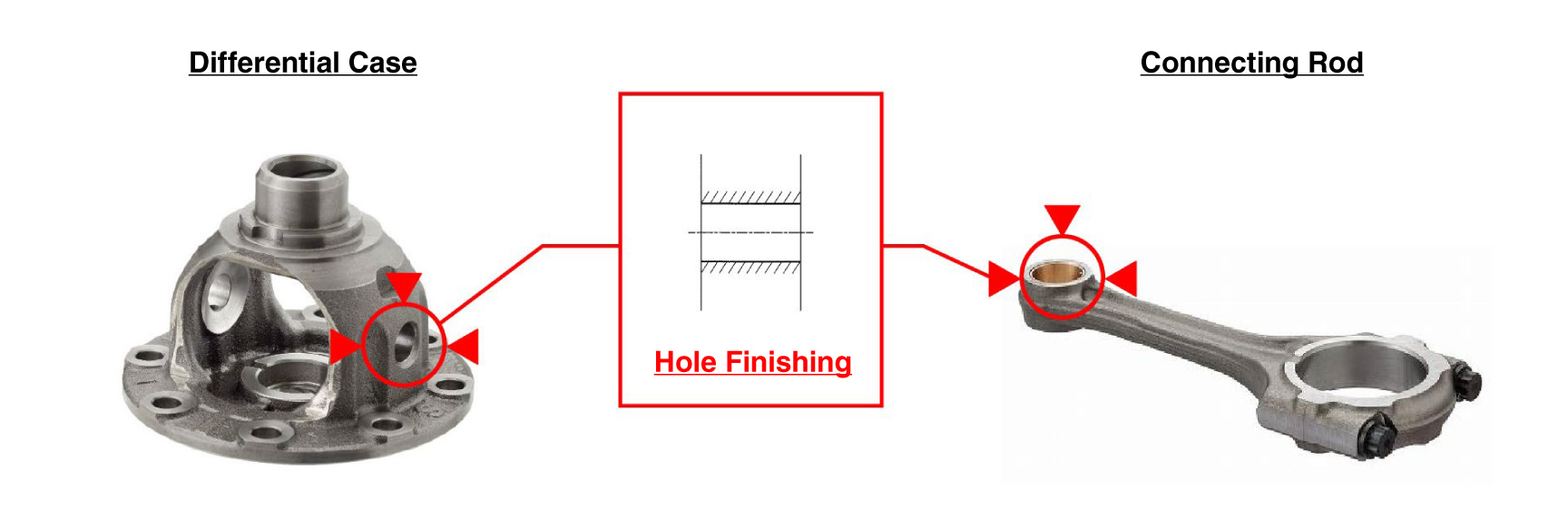

High-precision through-hole machining

can be achieved at a lower cost!

- Outstanding chip evacuation by

“GHI Reamer” + “Shank-through”!

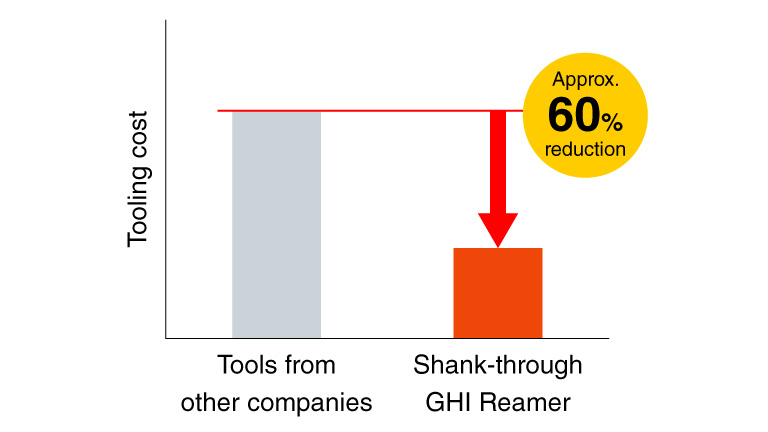

- Reduced tooling costs by using inexpensive standard materials

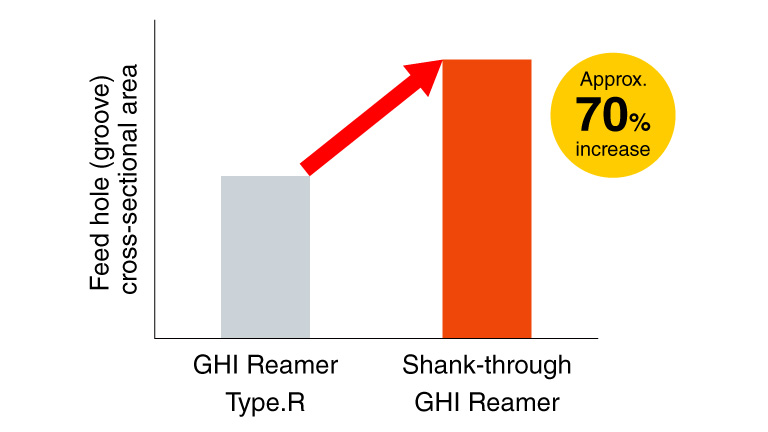

- High chip evacuation by left-hand twisting + shank-through

- High-precision machining unique to GHI reamers

“Amazing Ideas / Facts!”

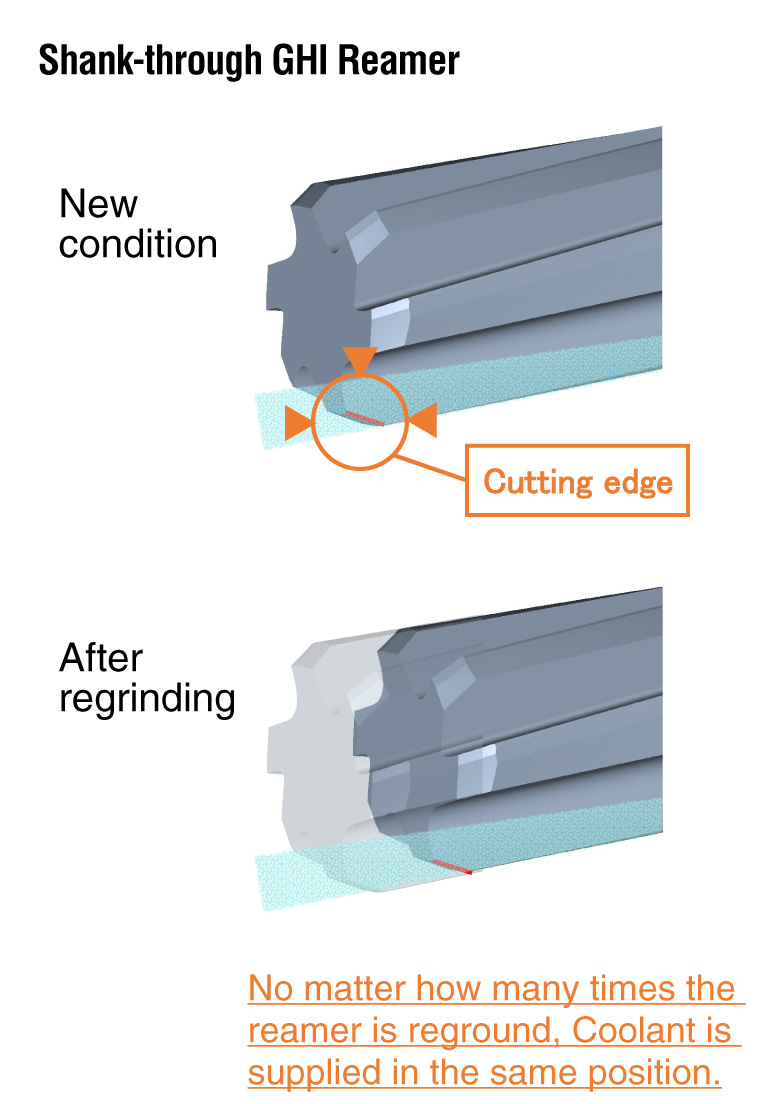

Shank-through GHI reamers have a coolant groove on the shank periphery, which contributes to lower tool costs by using inexpensive standard materials.

It can supply sufficient coolant to each cutting edge and maintain the same machining condition even after regrinding.

The left-hand twisting suppresses coolant diffusion when the rotation speed is increased and improves forward chip evacuation.

Reduced tooling costsGood !

Increased coolant supplyGood !

POINT!

Improved chip evacuation due to coolant supply from shank groove and diffusion control effect of left-hand twistingExcellent !

POINT!

80% increase in number of regrinds due to stable coolant supply even after regrinding.Excellent !

Background / Point for Development

Background

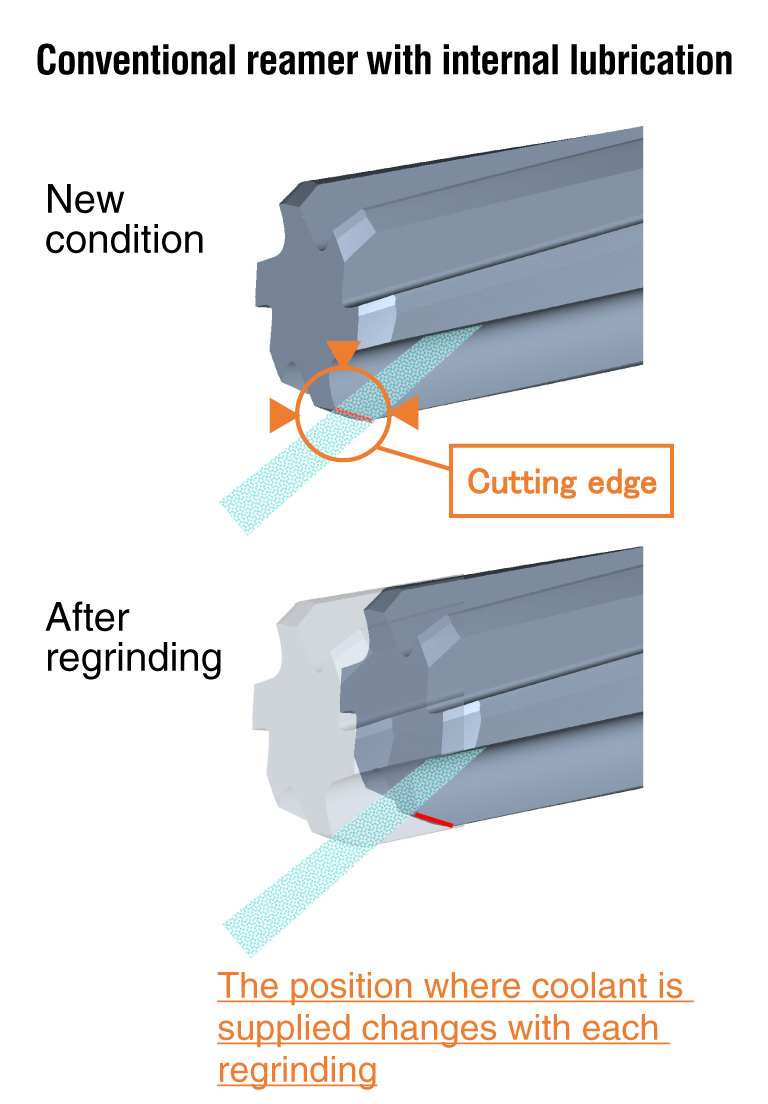

- Conventional through-hole reamers can supply coolant directly to the cutting edge, but require special materials, driving the cost up.

- Each time the number of regrinds, the position where coolant is supplied changes, which reduces cooling and chip evacuation performance. These may cause problems during machining.

Point for Development

- Developed a reamer that does not change the position where coolant is supplied even after redrinding.

- Reduce running costs by reducing material costs.

Example

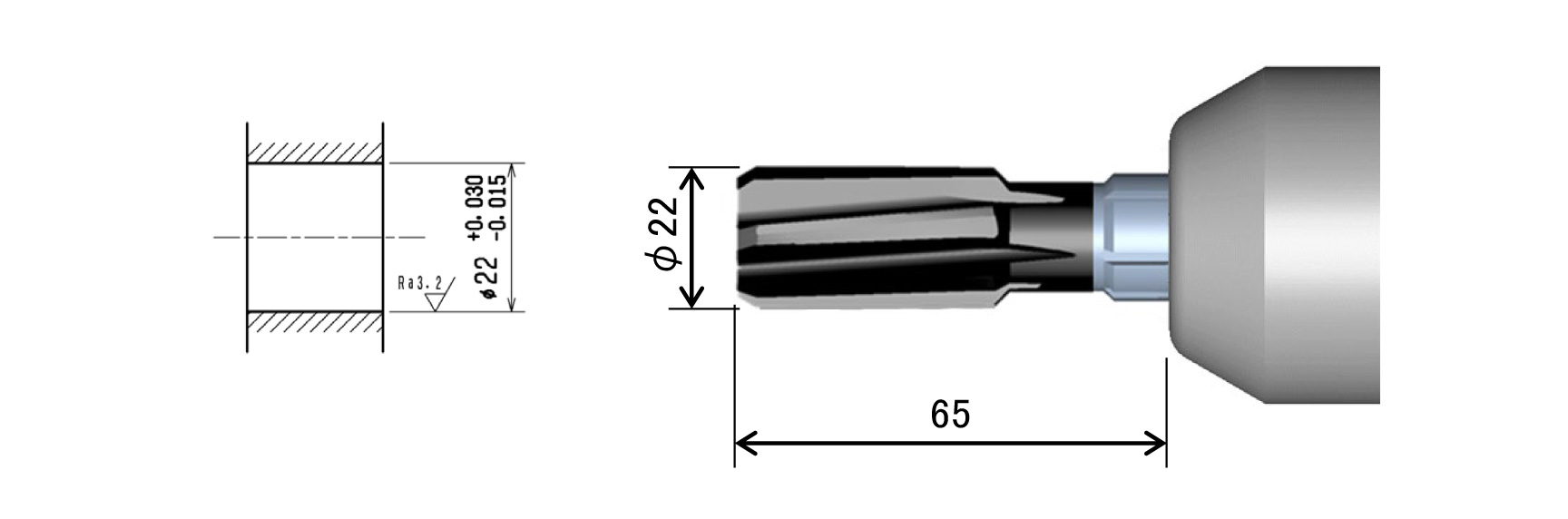

| Tool | Shank-through GHI Reamer |

|---|---|

| Workpiece | Connecting rod small end hole |

| Material | Special carbon steel |

| Tool diameter | ø22 |

| Cutting conditions |

|

| Allowance | ø0.5 mm |

| Required accuracy |  |

|---|

Product Specification

Tool specification (for through-hole only)

| Process covered | FC/FCD/steel finishing |

|---|---|

| Diameter | ø14 - ø24 |

| Standard Conditions |

|

| Performance | Processing diameter: IT7 class Surface roughness: Ra3.2 or less |

Example of adaptive work