Transporting Slipper

Evolutionary slippers carry

and protect anything

- Optimized structure of transfer jig

- Slippers suitable for a wide variety of products and workpiece protection

- Upper and lower jig structure for multiple products

- Plastic pins prevent workpiece damage

- Low cost and quick delivery by utilizing 3D printers

“Amazing Ideas / Facts!”

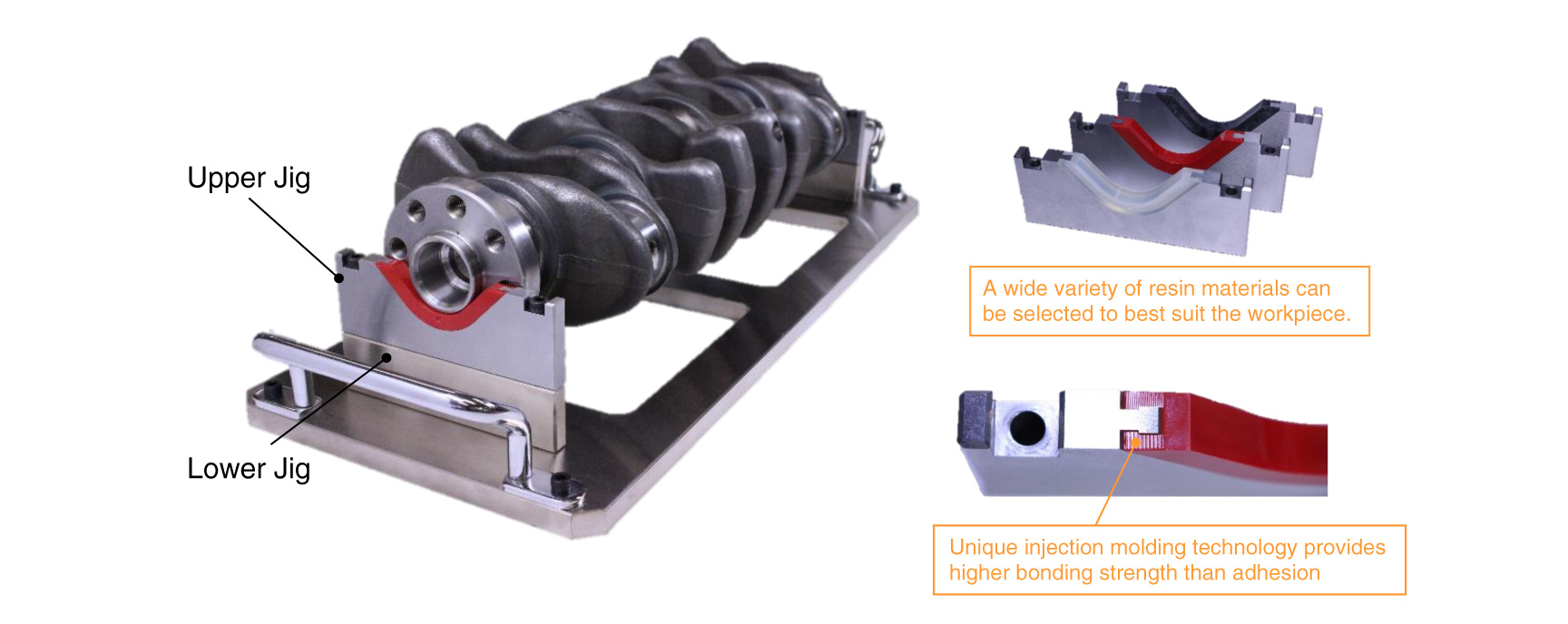

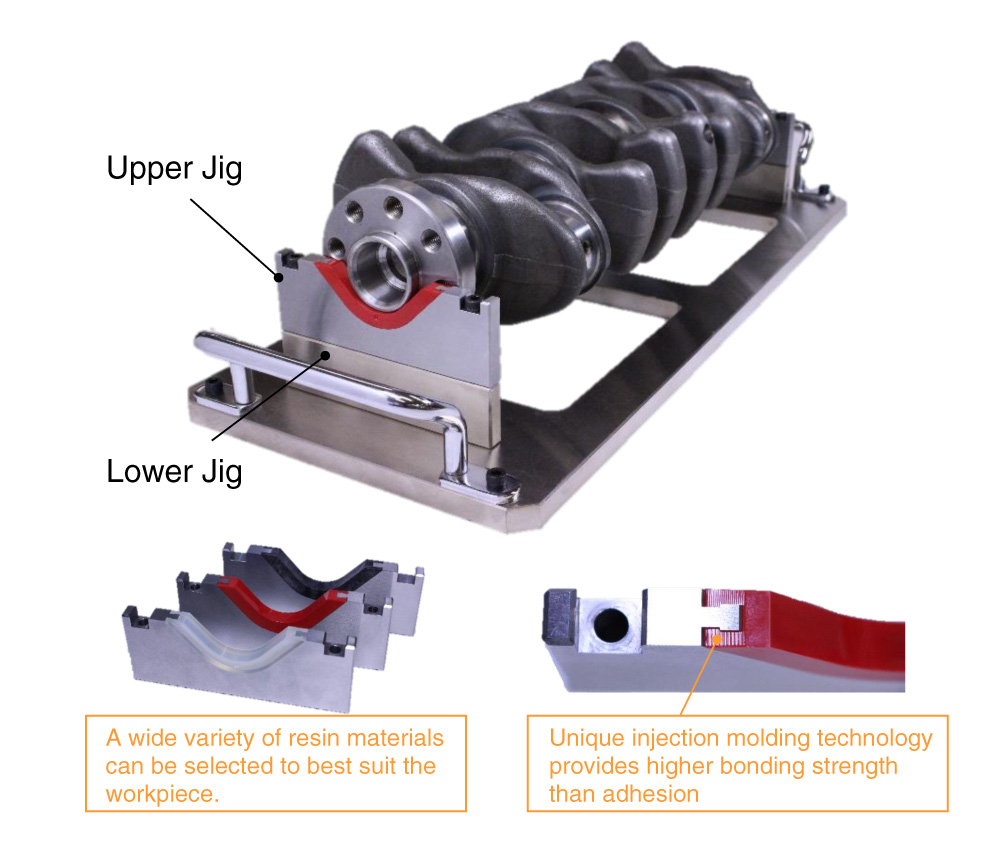

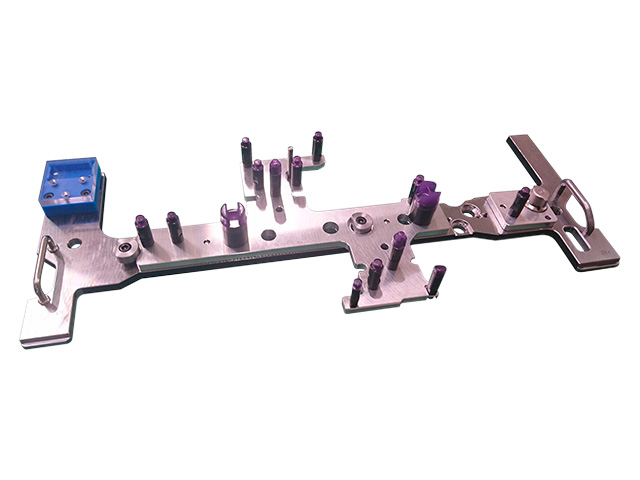

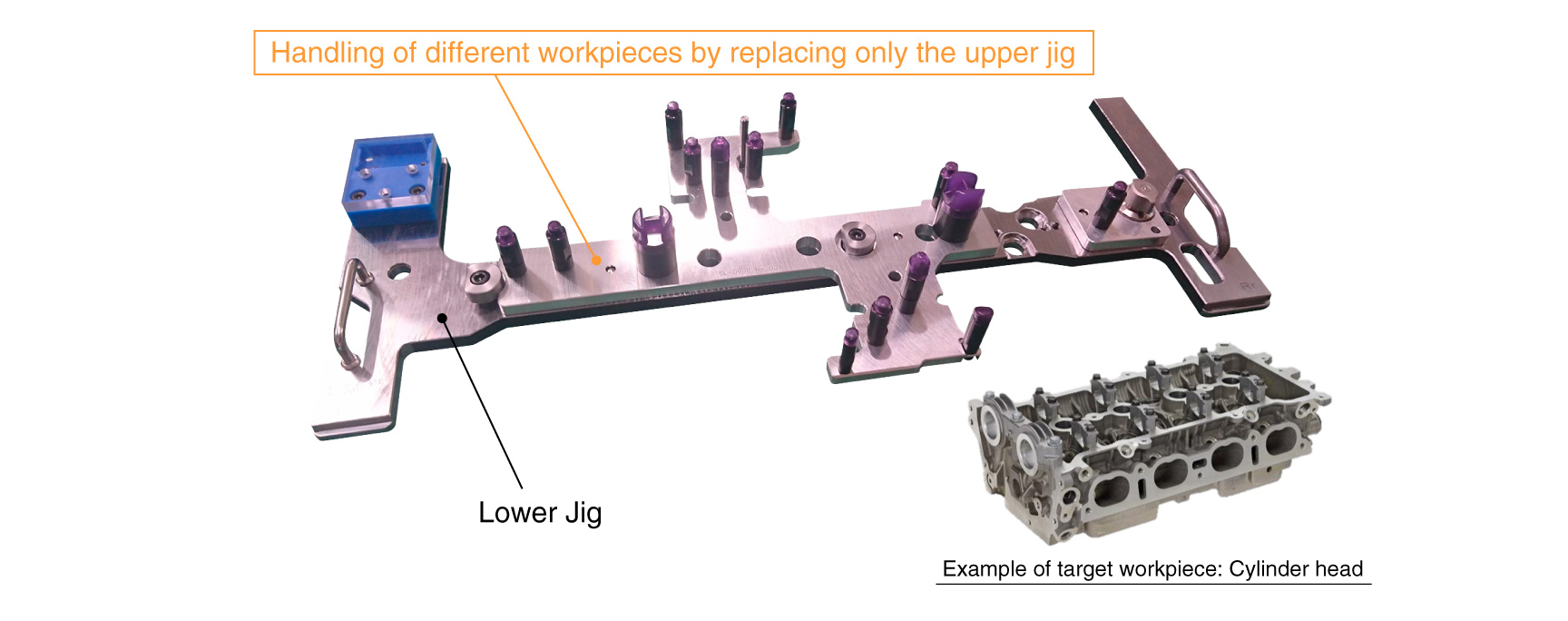

The “Transporting Slipper” consists in an upper jig and a lower jig.

A variety of workpieces can be transported by replacing only the upper jig.

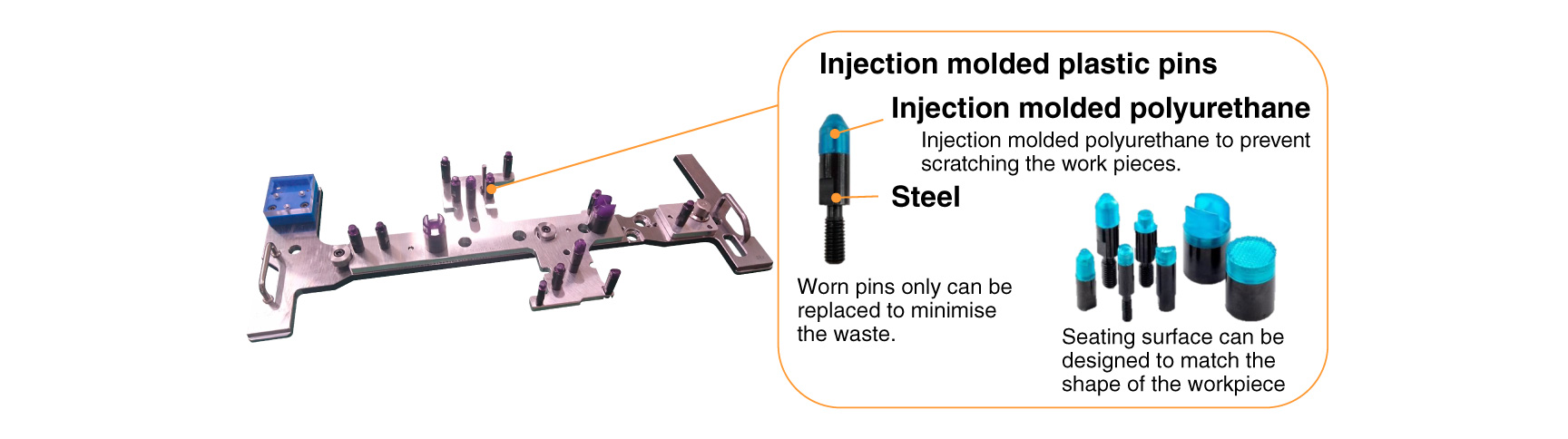

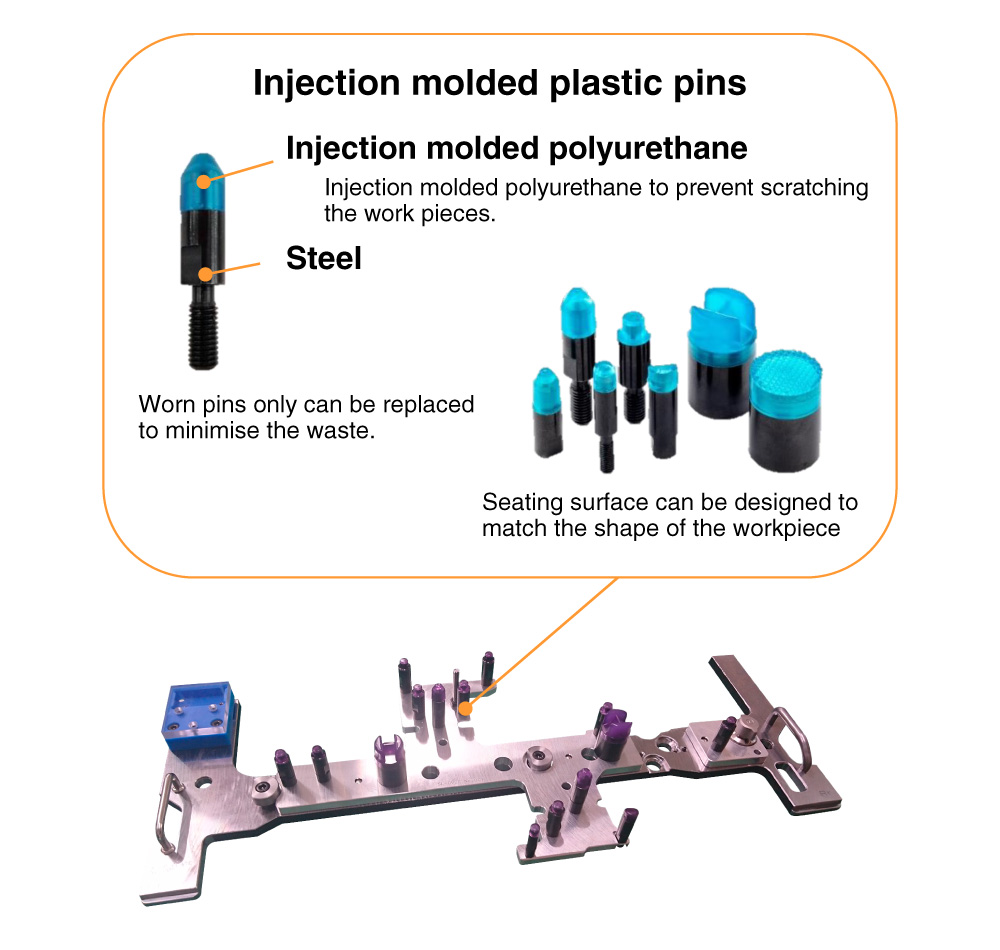

The pins are made of molded resin, to prevent workpieces from damaging.

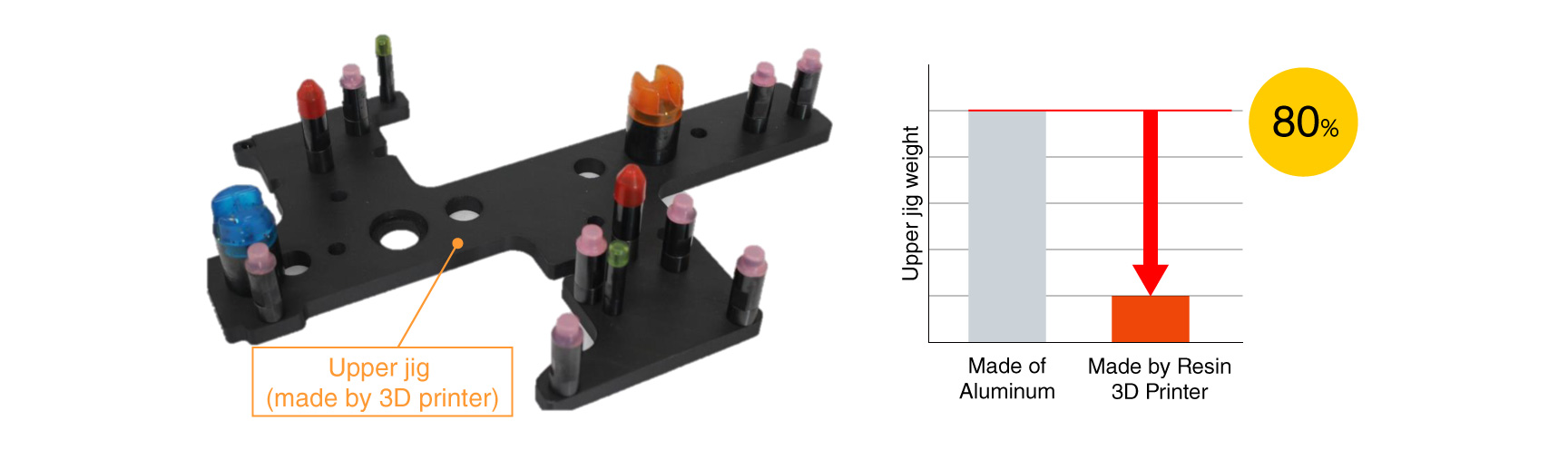

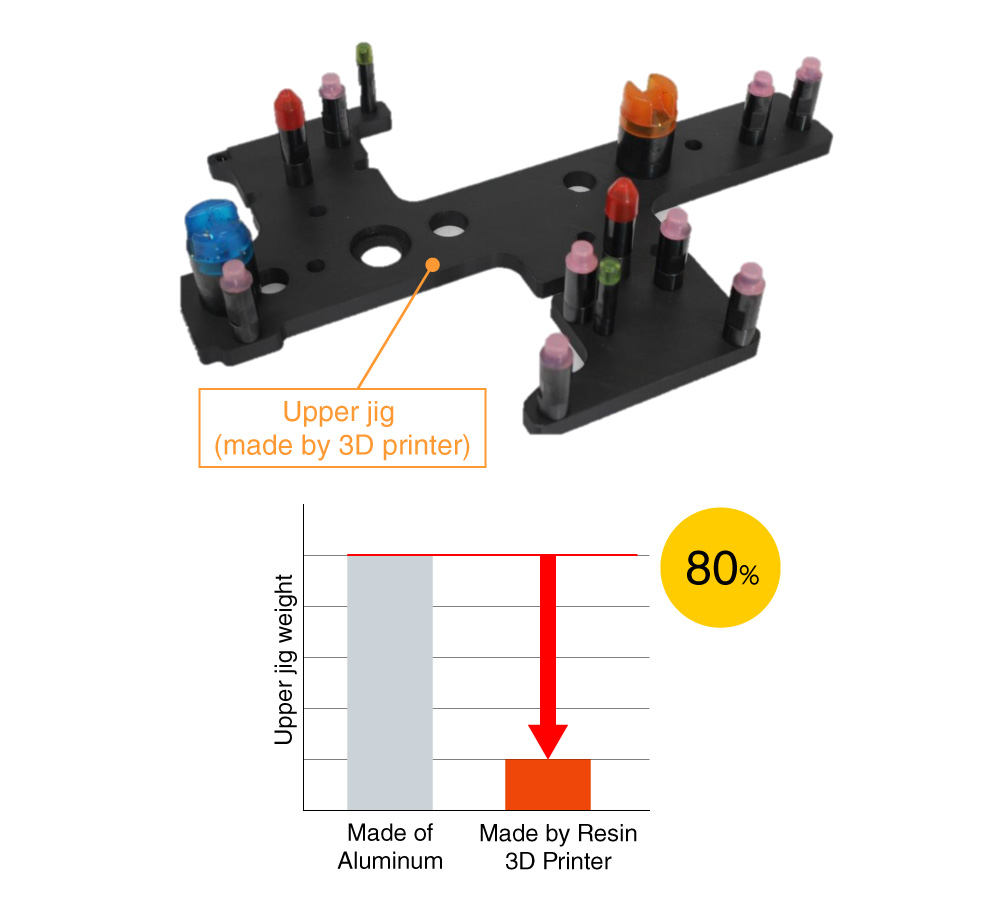

The entire jig can be manufactured by 3D printing technology, to achieve lightweight and quick delivery.

Upper jig and lower jig structure for multiple product typesGood !

Resin pins prevent workpiece damageGood !

Lightweight and quick delivery through the use of 3D printersGood !

Lightweight for easy jig replacement

Quick delivery is possible

Background / Point for Development

Background

- Usually transporting slippers are costly because they have to be made to fit each product type.

- Normally, hard material such as MC nylon or steel is used for pins which directly contact and thus risk of damaging the work surface. Also, in the case of MC nylon, chips can stick and cause line stop.

Point for Development

- The “Transporting Slipper” has a split upper jig and lower jig to reduce investment costs by replacing only the upper jig when changing products.

- The unique resin material and processing technology prevent surface scratches on workpieces.

Other Adoption Cases

Example: Crankshaft