TFH Drill

Towards a new realm

of high-efficiency aluminium machining!

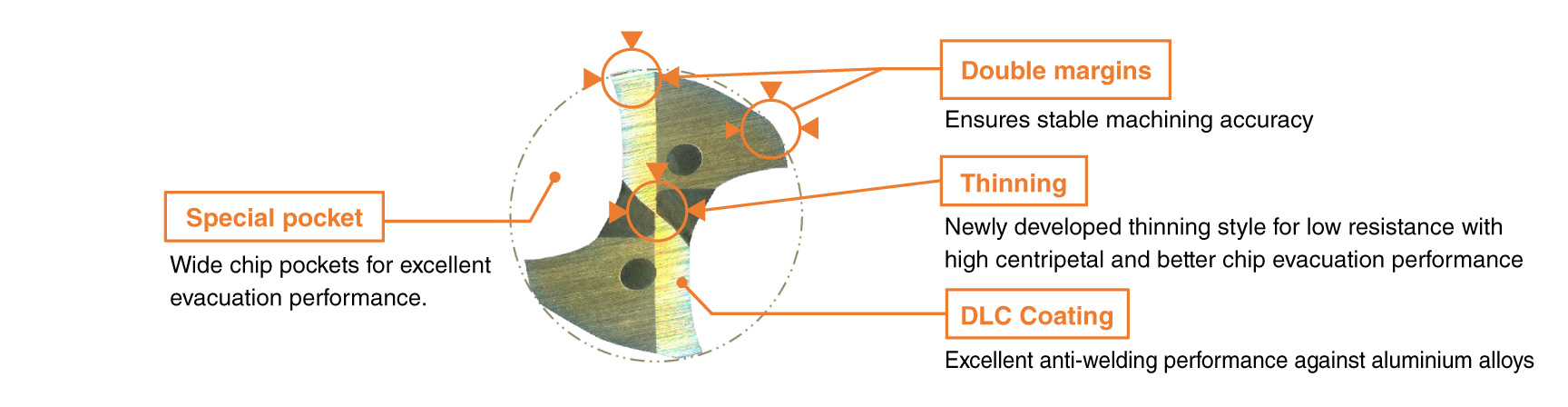

- Highly efficient machining of aluminium alloys with ‘low-resistance thinning’ + ‘double margin’

- High feed rate of drill diameter × 15% (mm/rev)

due to low-resistance thinning - Stable machining accuracy with double margins

- DLC coating improves resistance to welding

“Amazing Ideas / Facts!”

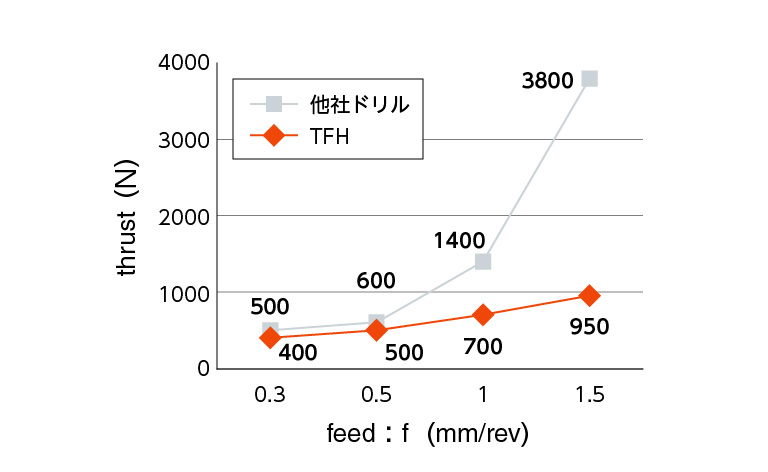

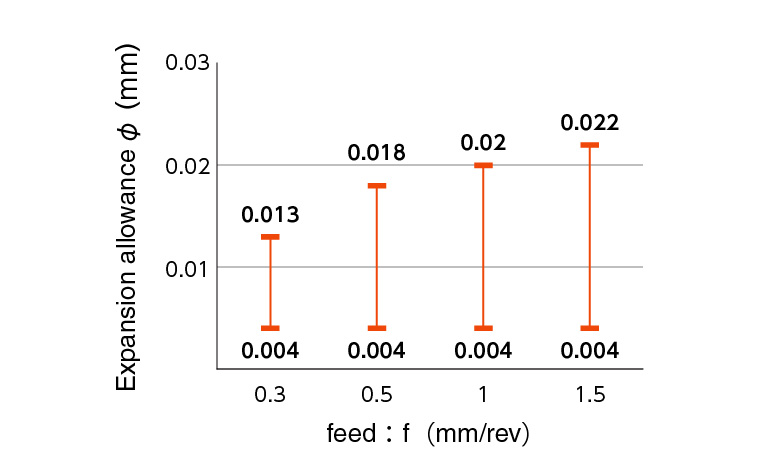

The TFH drill realises low thrust and stable machining accuracy due to its special thinning and double margins, which enable the high feed rates equivalent to 15% of the drill diameter.

Reduction of cutting resistance (thrust)Good !

Allowance of Diameter expansionGood !

POINT!

Low resistance and stable machining accuracyExcellent !

Background / Point for Development

Background

- High efficiency and reduced cutting resistance are essential in drilling operations to reduce investment cost for equipments and the machinery down-sizing.

Conventional twisted drills usually have higher thrust and poorer chip evacuation, making it difficult to reduce overall machining time.

Point for Development

- The TFH drill features a newly developed thinning shape for low thrust and a special flute shape for improved chip evacuation, enabling high feed rate of drill diameter × 15% (mm/rev).

- The double margin ensures stable machining accuracy and contributes to improved productivity in a wide range of applications.

Product Specification

Tool Specification

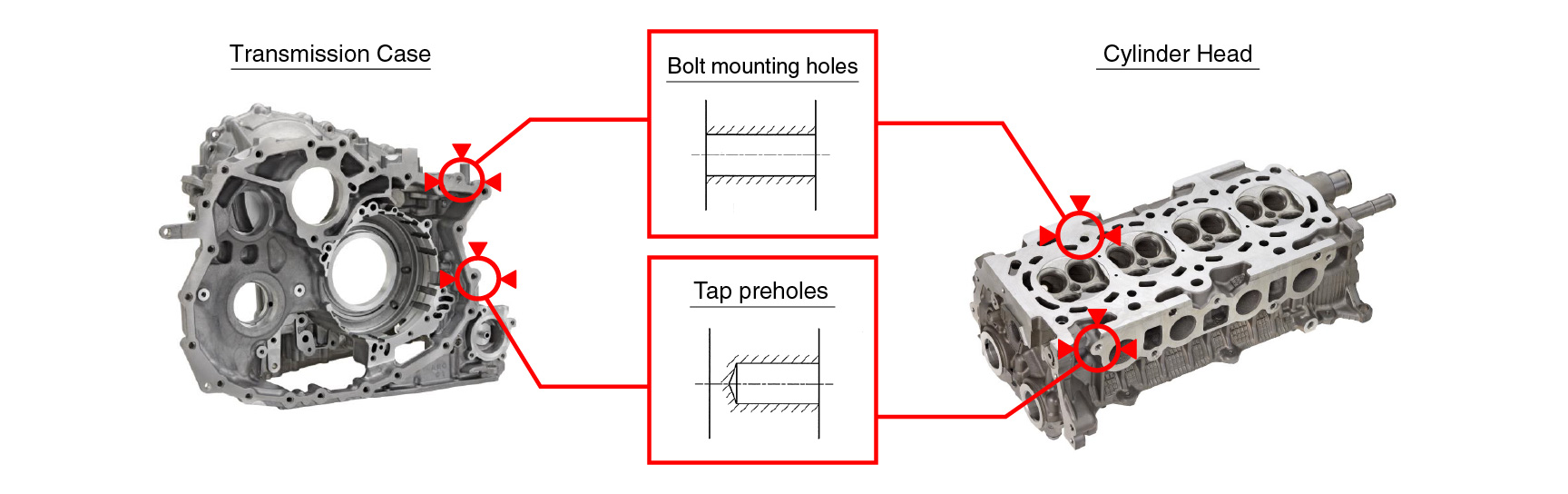

| Process covered | Aluminum general hole (w/o preholes) |

|---|---|

| Diameter | ø4mm - |

| Standard conditions |

|

| Performance | Accuracy: IT9 Surface roughness: Rz25 Machining hole depth: L/D≤5 Positional tolerance: ø0.6 |

Example of workpieces