TFS Drill Series

Machining wide range of materials,

including cast iron and steel!

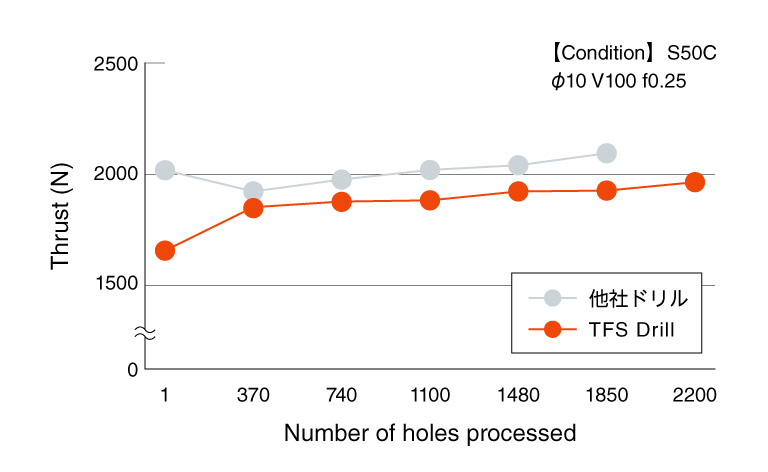

- Low resistance thinning + Optimal flute shape achieve highly cutting capacity, even for cast iron and steel!

- Low thrust by low resistance thinning

- High chip evacuation by optimal twist angle & flute shape

- High wear resistance by multi-layer coating

About TFS Drill Series

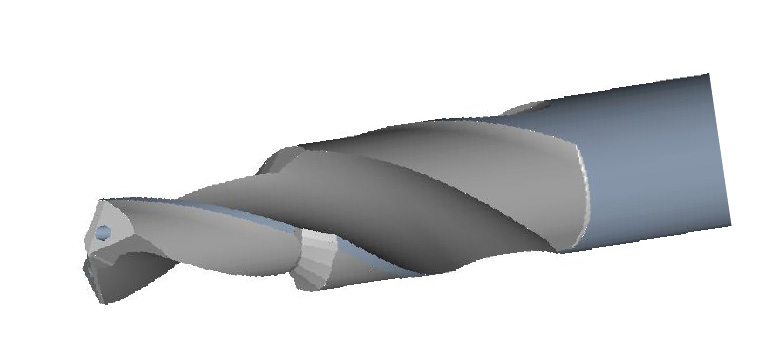

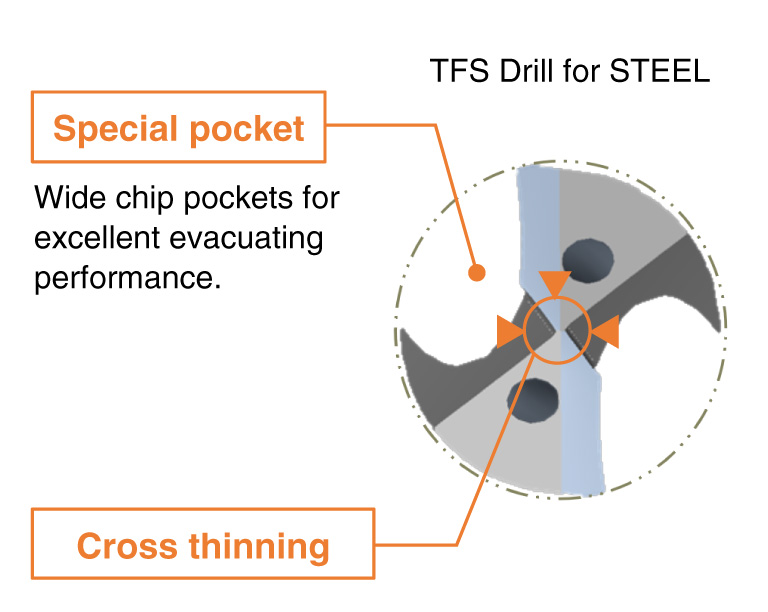

①TFS Drill

For general hole machining: STEEL

Features: Excellent chip evacuation by low resistance edge and special flute shape.

- Cross-thinning

- Single margin

- Multi-layer coating

- IT 9 class accuracy

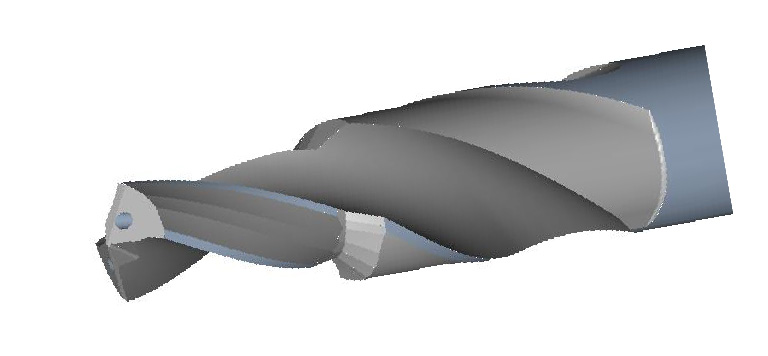

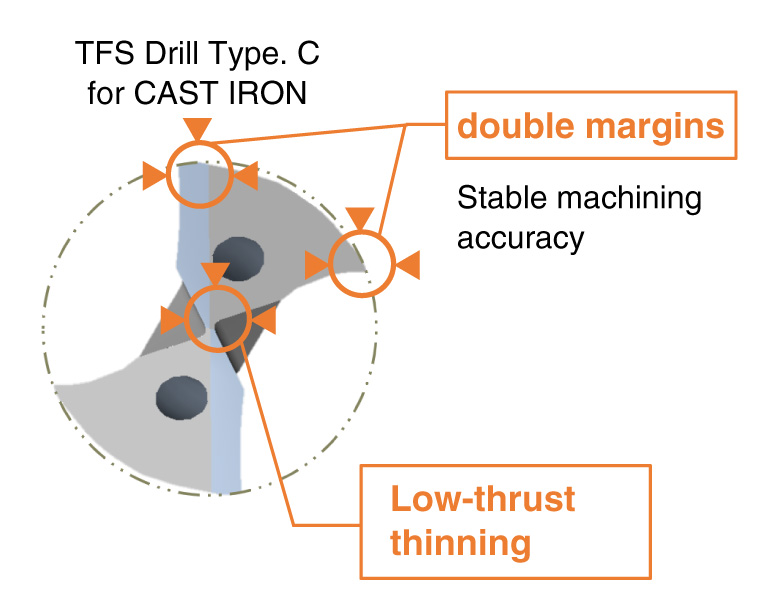

②TFS Drill Type.C

For general hole machining: CAST IRON

Features: Specially dedicated cutting edges for cast iron machining.

- Low thrust thinning

- Double margin

- Multi-layer coating

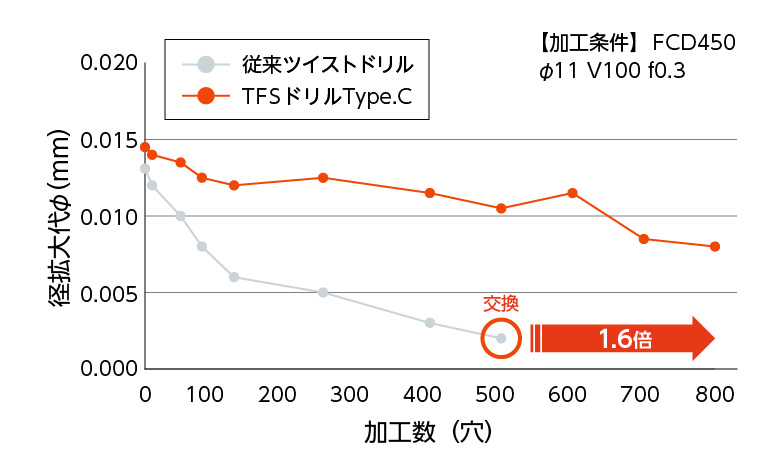

- Improved life in cast iron machining compared with conventional drills

- IT 9 class accuracy

“Amazing Ideas / Facts!”

The TFS Drill uses straight shape cutting edges and double cross-thinning to ensure cutting edge strength and low thrust.

The flute shape is specifically designed for better chip evacuation.

The TFS Drill Type C uses low-thrust thinning and double margins for stable/accurate machining of cast iron.

Both drills feature a dedicated multi-layer coating as a standard to improve wear resistance.

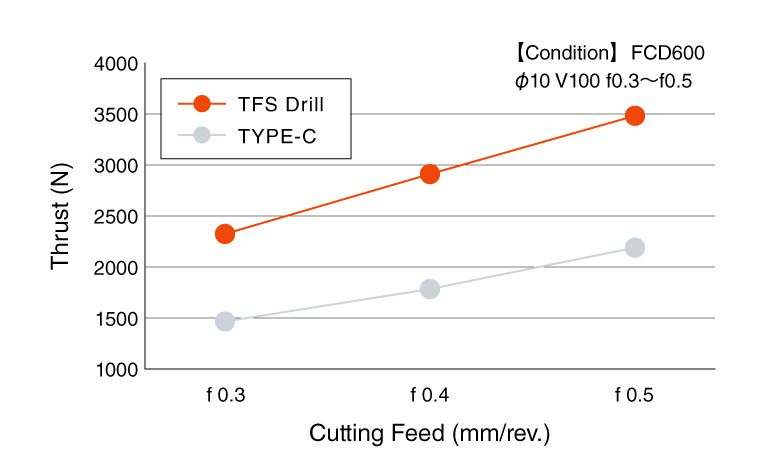

TFS Drill: Reduction of cutting resistance (thrust)Good !

TFS Drill Type.C: Reduction of cutting resistance (thrust)Good !

TFS Drill Type.C: Long life in cast ironGood !

POINT!

Unique specifications for different work piece materialsExcellent !

Background / Point for Development

Background

- In the machining of cast iron and steel, thrust resistance was high and chip evacuation was poor.

Thus difficult to improve efficiency to ensure the machining accuracy.

The cutting heat also tends to go high which resulted in short tool life.

Point for Development

- The TFS Drill has a wider twist flute shape for more efficient chip evacuation and the cutting edge shape suitable for machining steel with low cutting resistance.

- The Type.C has a special thinning shape to reduce thrust, specially designed for cast iron machining.

- The double margin minimizes vibration and keeps high-precision during machining, while the use of a multi-layer coating significantly improves service life.

Product Specification

TFS Drill

Tool Specification

| Process covered |

general hole machining for steel |

|---|---|

| Diameter | ø4 - ø20 |

| Standard conditions |

|

| Performance | IT9 class |

TFS Drill Type.C

Tool Specification

| Process covered |

general hole machining for cast iron |

|---|---|

| Diameter | ø4 - ø20 |

| Standard conditions |

|

| Performance | IT9 class |

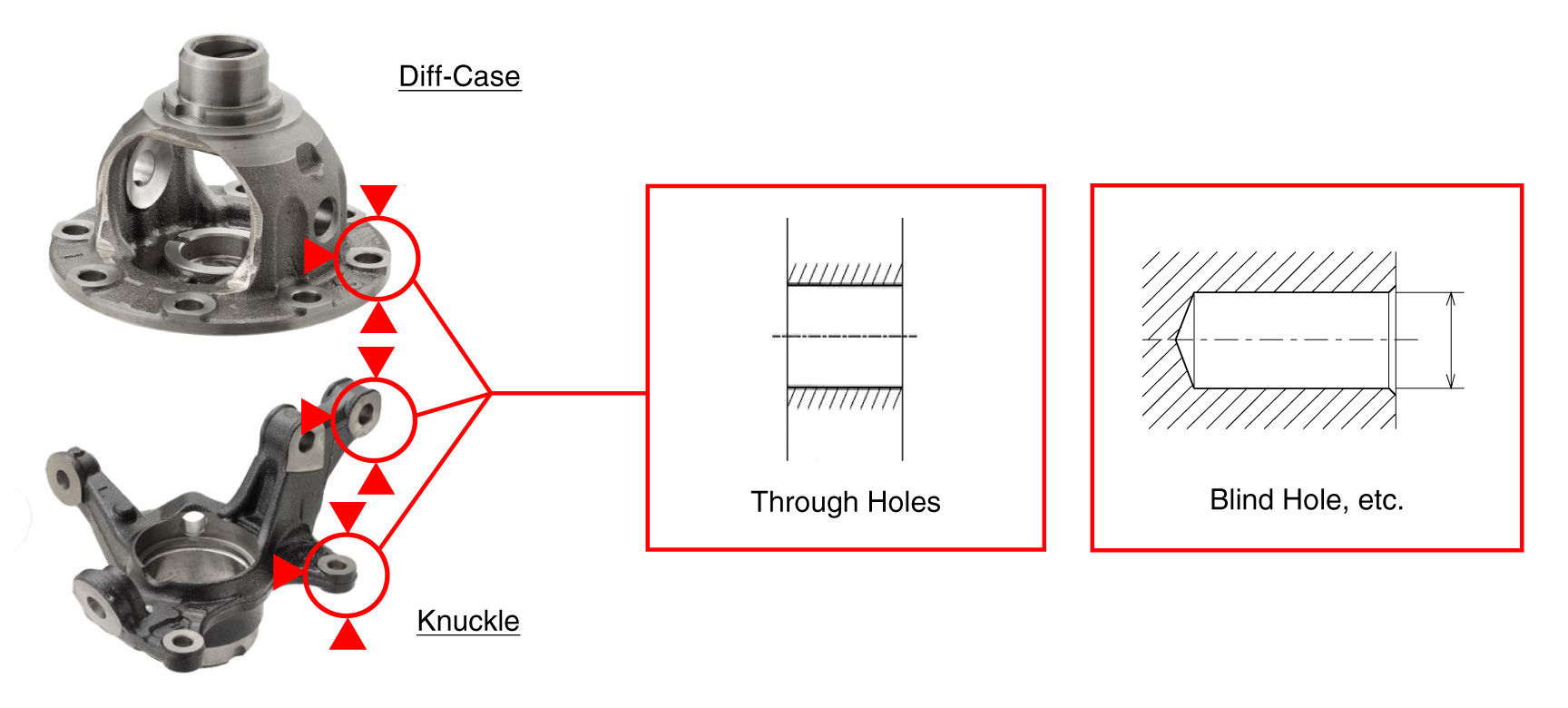

Example of Applicable Work