Traverse V/F

“Traverse machining of

valve seats” Leave it to us!

- Traverse type in high-precision manufacturing, contributing to the better productivity

- Machining of Valve seat and of Stem guide in one process

- Unique slider mechanism for longer service life

- Easy & simple tool changes for better productivity

“Amazing Ideas / Facts!”

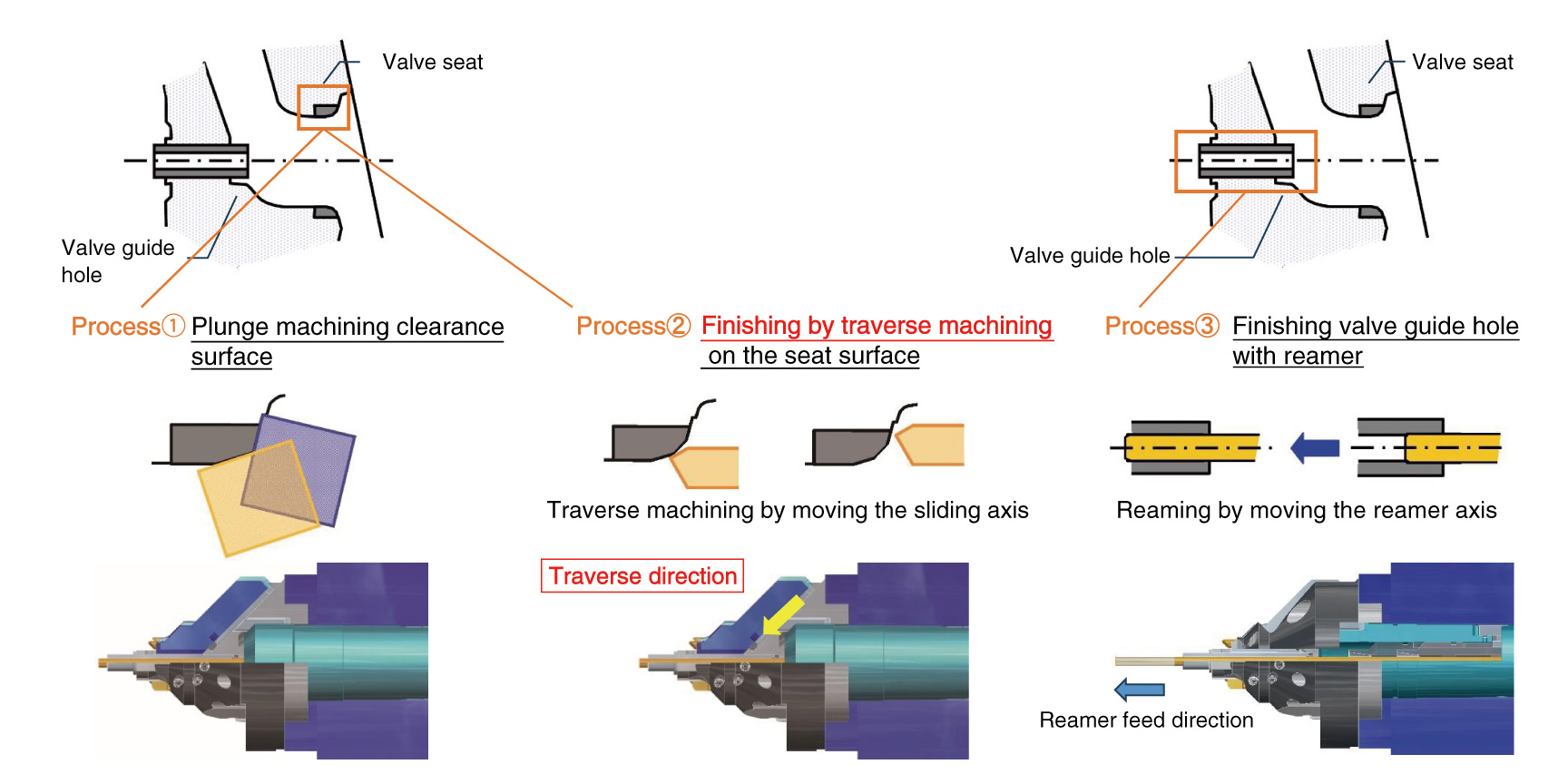

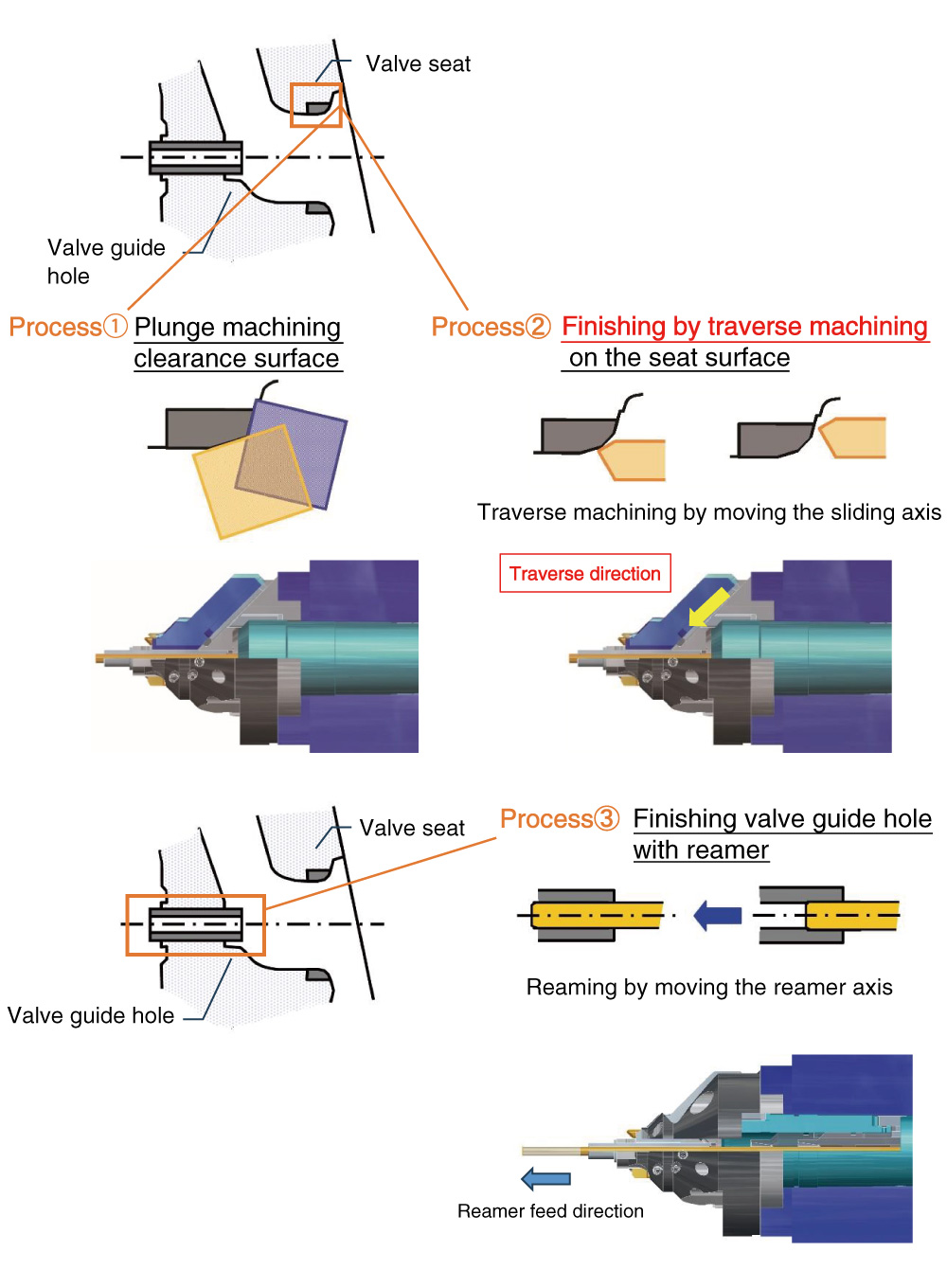

A traverse type of valve finisher (V/F) from our highly reliable and unique technology as a special tool maker, enables highly accurate machining.

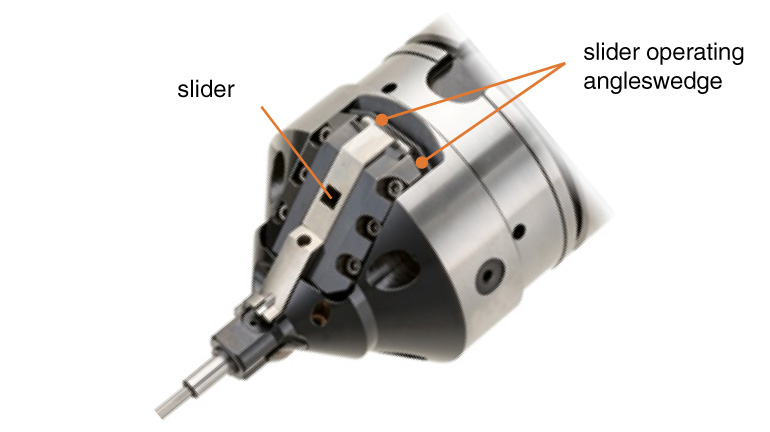

The slider, the key part to traverse machining, uses a unique mechanism to stabilize machining accuracy over the long term.

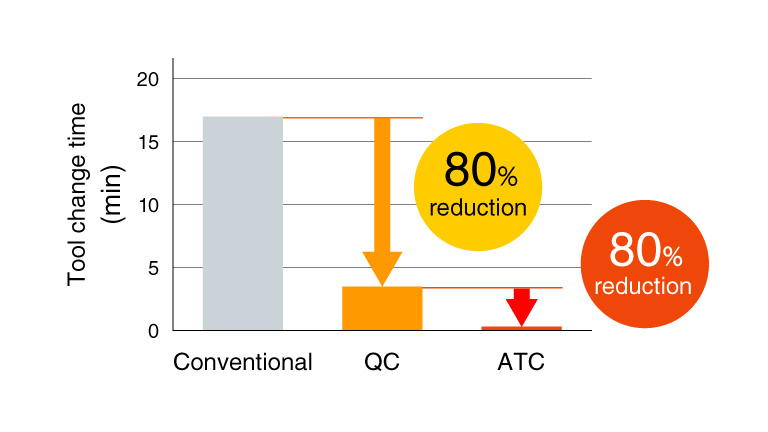

“Quick-Change” and “ATC” type are available, contributing to ‘multi-product support’ and ‘improved productivity’.

POINT!

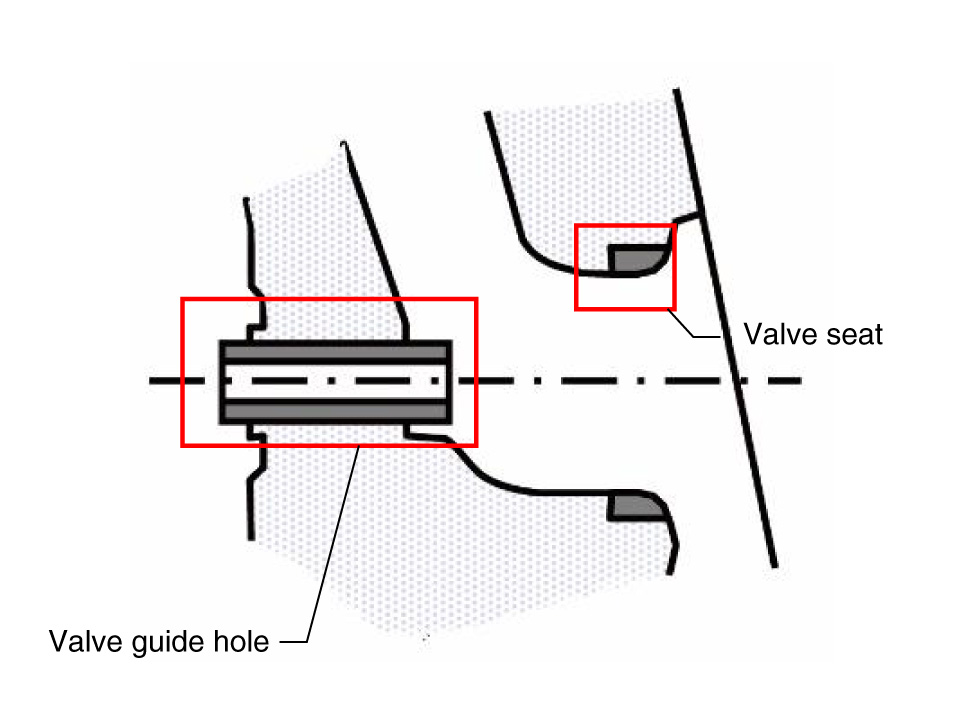

Traverse machining valve seats and valve guide in 1 processExcellent !

POINT!

Long-life slider with unique mechanismExcellent !

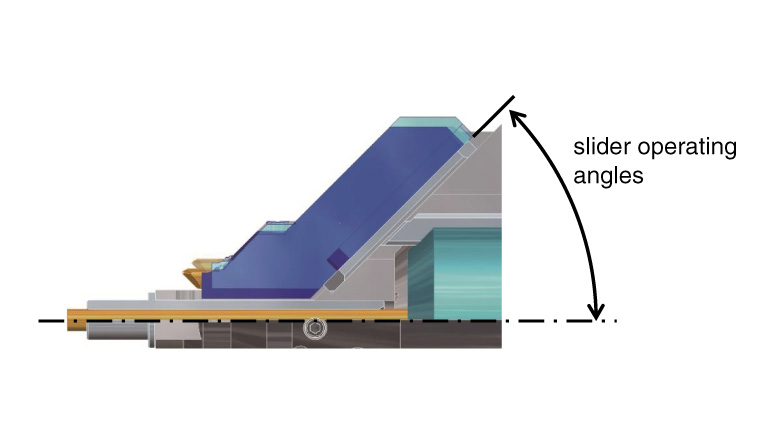

Unique slider mechanism using wedge pressing pressure for stable machining accuracy over the long term.

Unique technology to produce slider operating angles with high precision.

Contributing to ‘multi-product production’ and ‘increased productivity’.Good !

Quick-change and ATC specifications were developed to reduce tool-changing time and improve productivity.

Direct installation ver.

Equipment specification: dedicated machine

Shortest protruding length from spindle

Quick change ver.

Equipment specification: dedicated machine

Quick changeover

ATC ver.

Equipment specification:

M/C (with drawbar)

Suitable for multi-product production

Automatic tool change

Background / Point for Development

Background

- Traverse type of valve finishers were mainly made overseas, and often had problems with tool unit price, delivery time and after-sales support.

- It took longer setting up time on a machine spindle, due to the complicated installation work involved.

Point for Development

- Our highly reliable and unique technology enabled the domestic production of “Traverse V/F” (Valve Finisher), reducing its maintenance costs by extending the tool life.

- The quick-change technology, developed in tool manufacturing is incorporated also for the valve finisher, to improve the efficiency of tool changing.

Example

| Workpiece | Cylinder head, valve guide hole |

|---|---|

| Material | Sintered metal |

| Tool | ø5.5mm 1-edge carbide reamer |

| Cutting Conditions | Revolution: N=3500min-1 Cutting speed: V=60m/min Cutting feed: f=0.15mm/rev |

| Allowance | ø0.3mm |

| Coolant | Internal lubrication |

| Workpiece | Cylinder head, valve seat |

|---|---|

| Material | Sintered metal |

| Tool | Brazed carbide bites |

| Cutting Conditions | Revolution: N=700min-1 Cutting speed: V=70m/min Cutting feed: f=0.05mm/rev |

| Allowance | 0.1mm |

| Coolant | External lubrication |