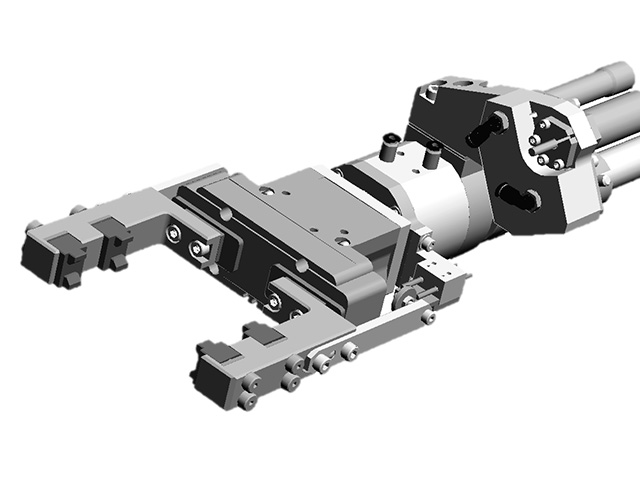

Flip Holder

Automated workpiece flipping

- Flipping workpiece without special equipment

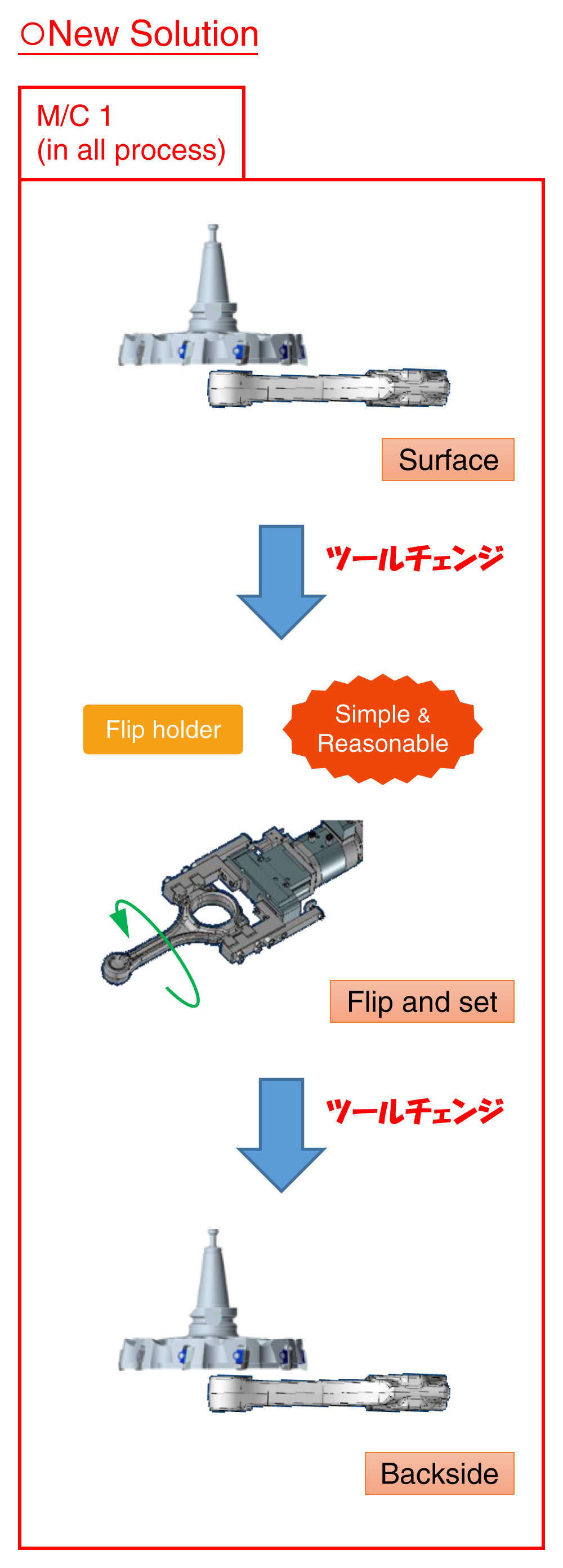

- “Flip Holder” that enables double-sided machining of workpiece within a M/C

- Simply mount on M/C

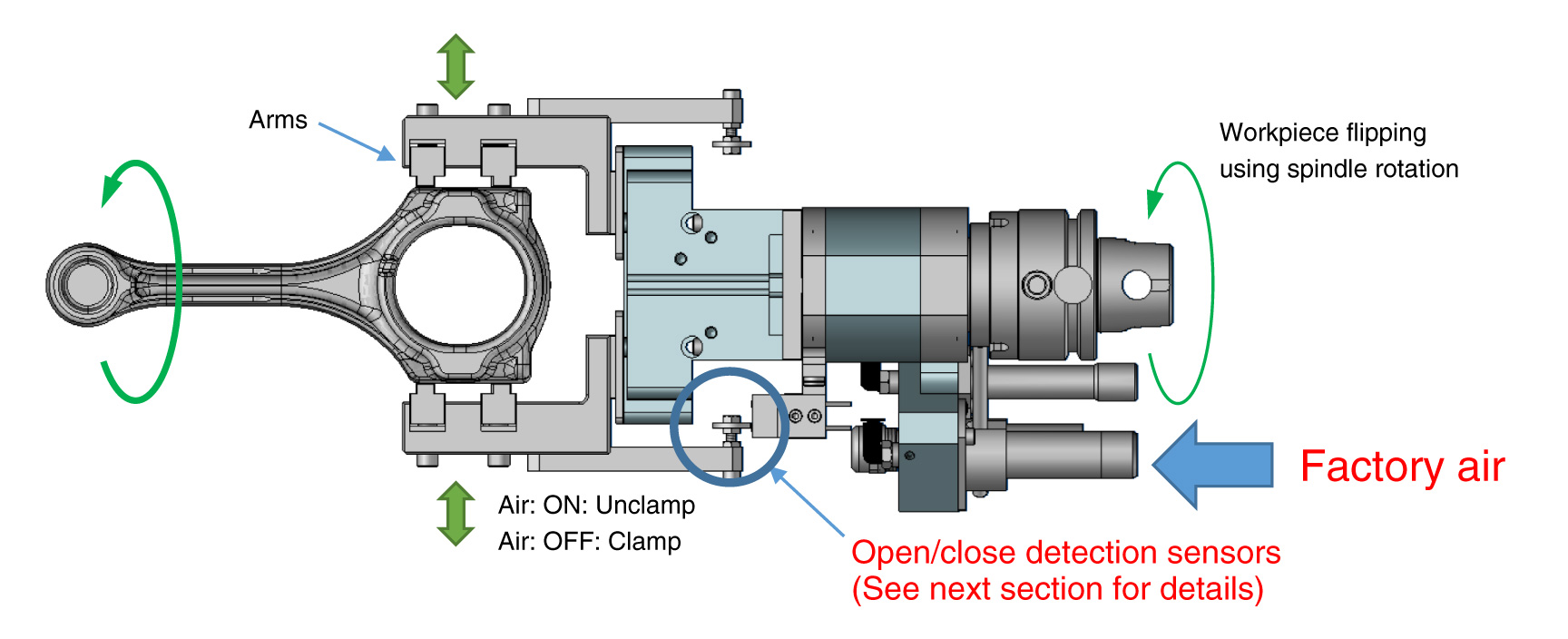

- Claws open and close with factory air

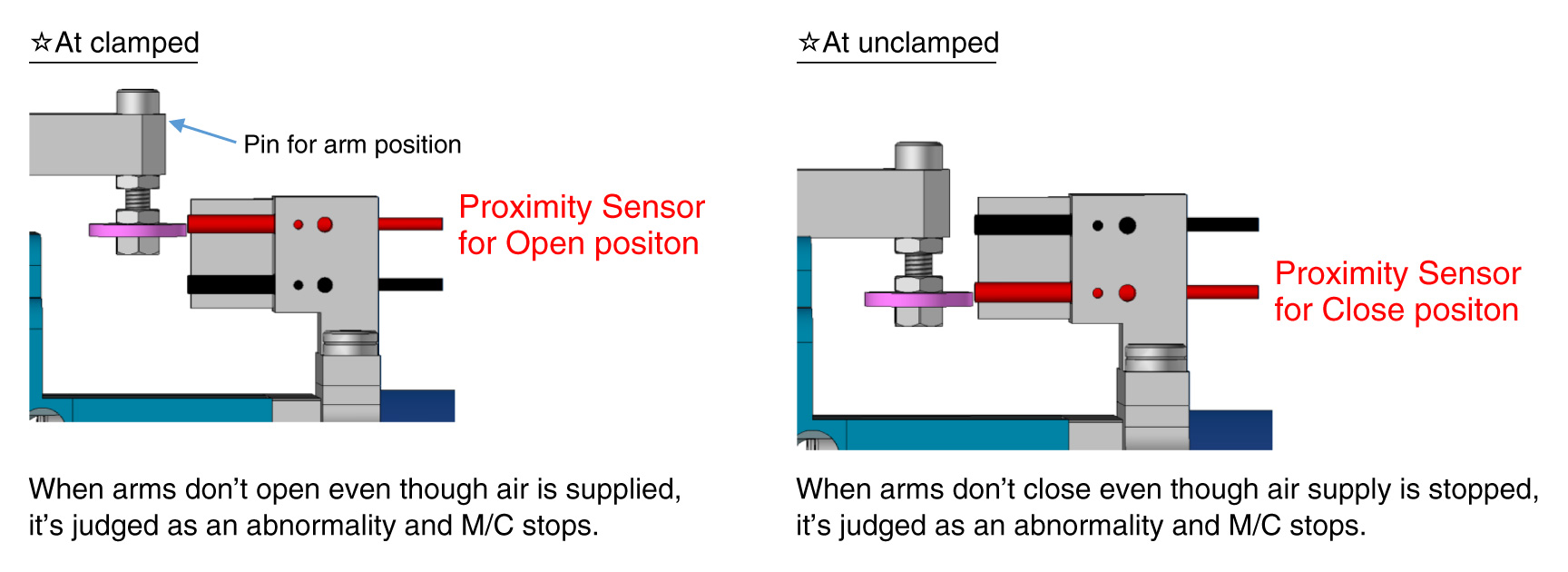

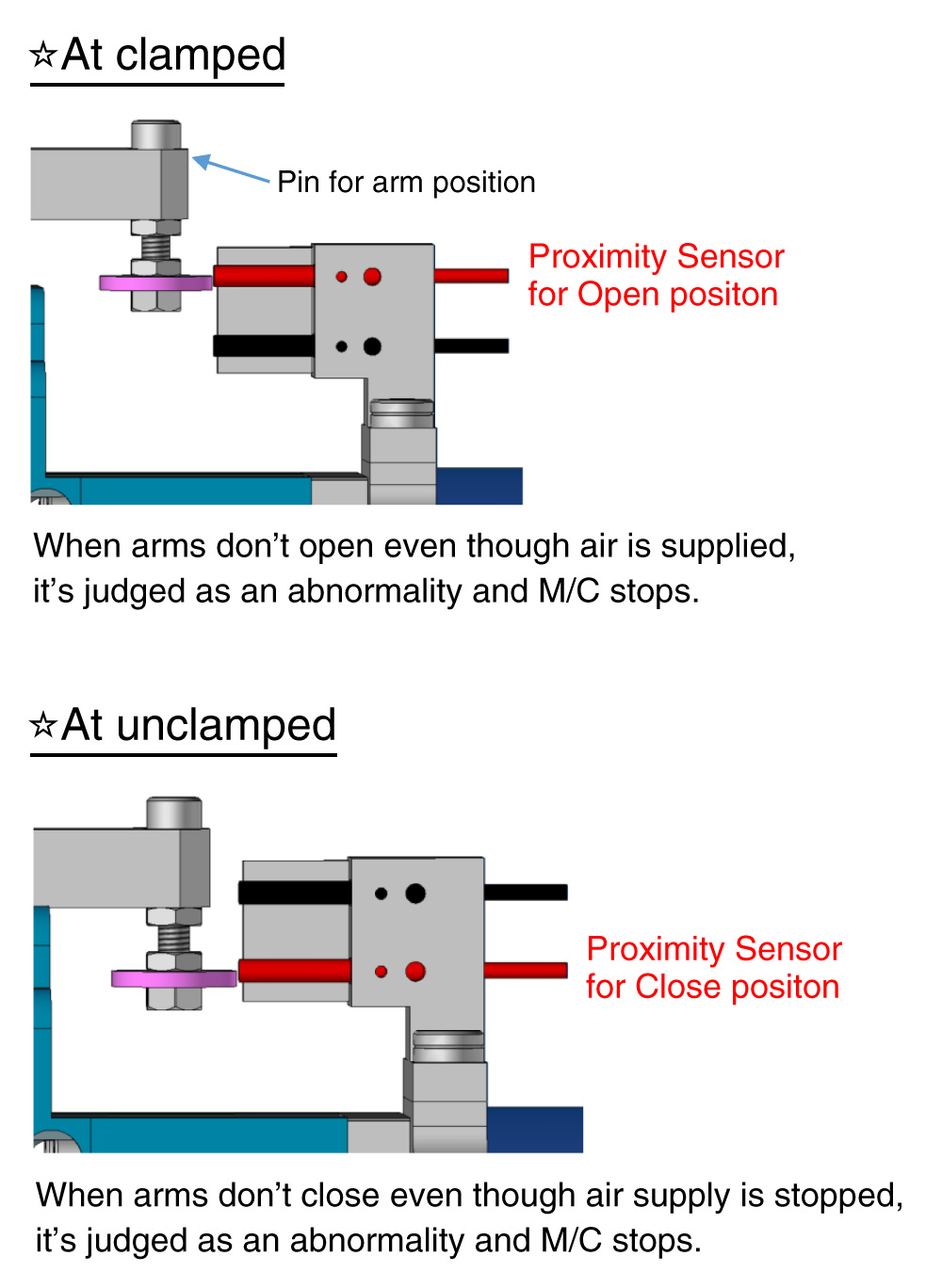

- Equipped with sensors to detect abnormalities

“Amazing Ideas / Facts!”

“Flip holder” utilizes factory air and spindle rotational power to flip workpiece simply by attaching it to a M/C.

In addition, proximity sensors are included to reliably detect the opening and closing of the arm and reliably detect abnormalities such as workpiece falling.

The holder does not require “Robots”,“Gantry Loaders”, or “Transfer Lanes” and eliminates “Manual workpiece orientation changes”.

Examples of Use

POINT!

Mechanism with factory air and spindleExcellent !

POINT!

Abnormality detection function by “Open/Close Detection Sensor”Excellent !

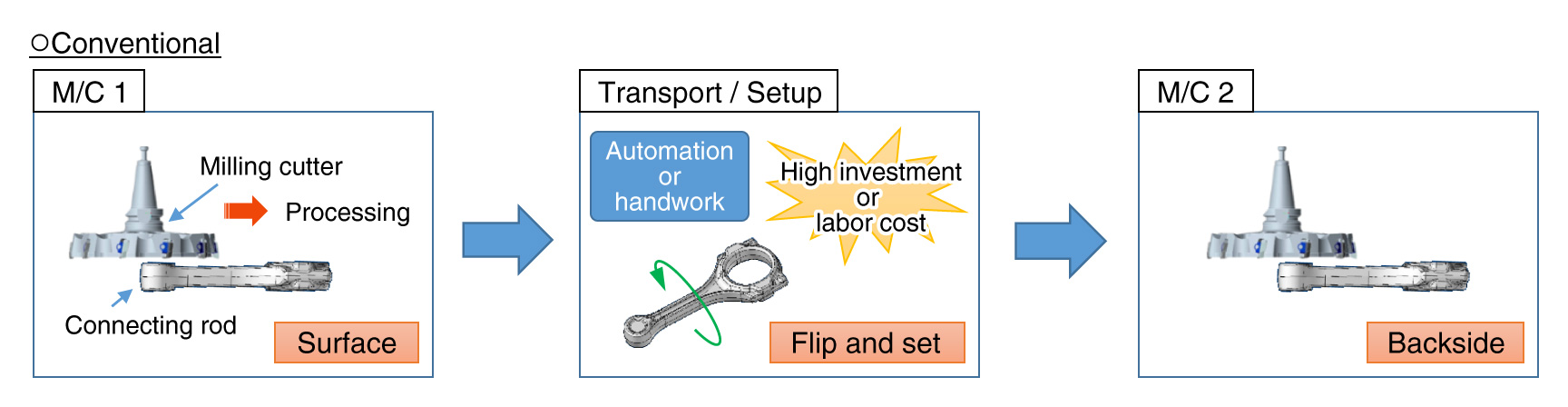

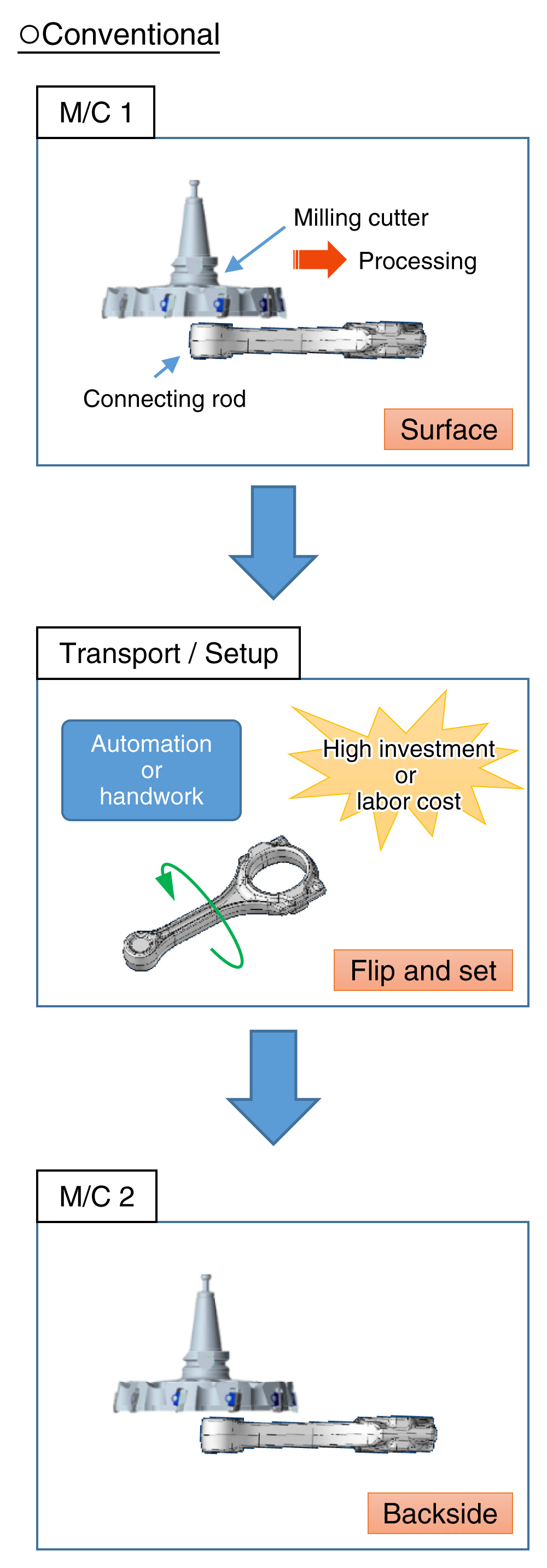

Background / Point for Development

Background

- Until these days, robots or gantry loaders had to be installed in a machining line in order to flip workpiece without operators, for which huge(large/big) investment and the considerable space were required.

- The industry was waiting for flipping functions without any special equipment or an extra investment, using the cheap, generic drive source within the same M/C.

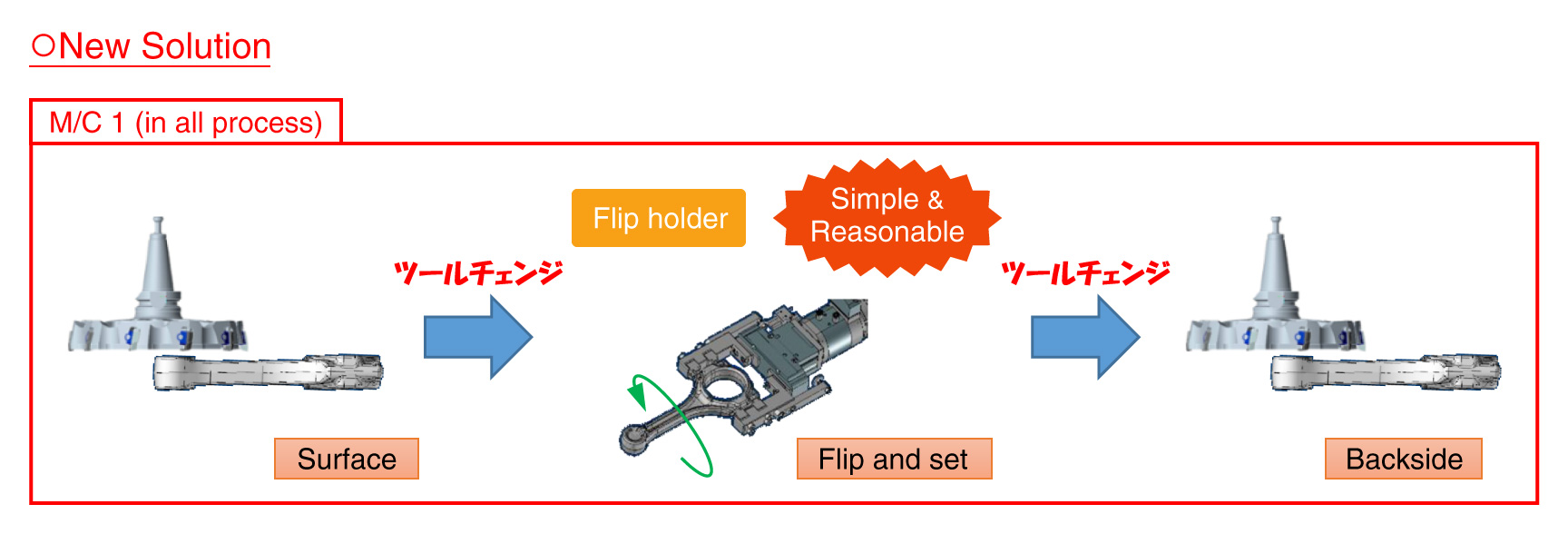

Point for Development

- “Flip Holder” is launched, utilizing factory air and the spindle rotation to automatically flip workpiece in M/C.

Product Specification

Tool Specification

| Driving Source | Factory air (0.6 MPa), Spindle of M/C |

|---|---|

| Grasping Power | 19 kgf (it can be adjusted) |

| Weight | 0.5 kg |

| Interface | HSK/HS/BT/CAPT etc. |

| Usable Machines | M/C/Combined lathe |

| Way of Grasping | Outside of workpiece |