Manmaru Z reamer

Stable & excellent finishing accuracy

even in intermittent cutting!

- ‘Excellent guiding properties’ + ‘PCD cutting edge’ for

high precision and intermittent holes

- Excellent machining accuracy due to all-round guide + single PCD edge

- Improved welding resistance by DLC coating

“Amazing Ideas / Facts!”

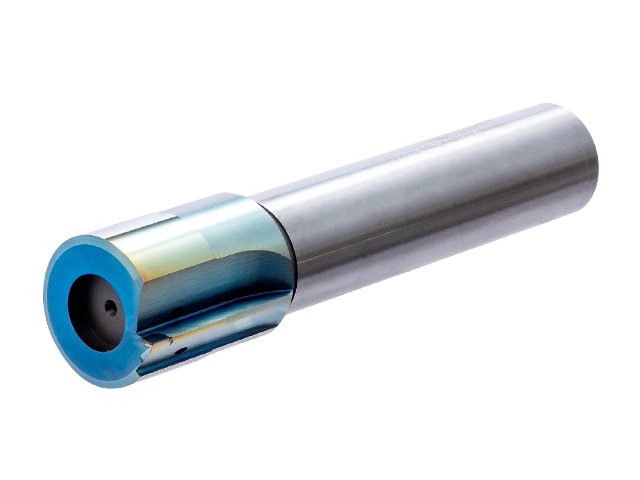

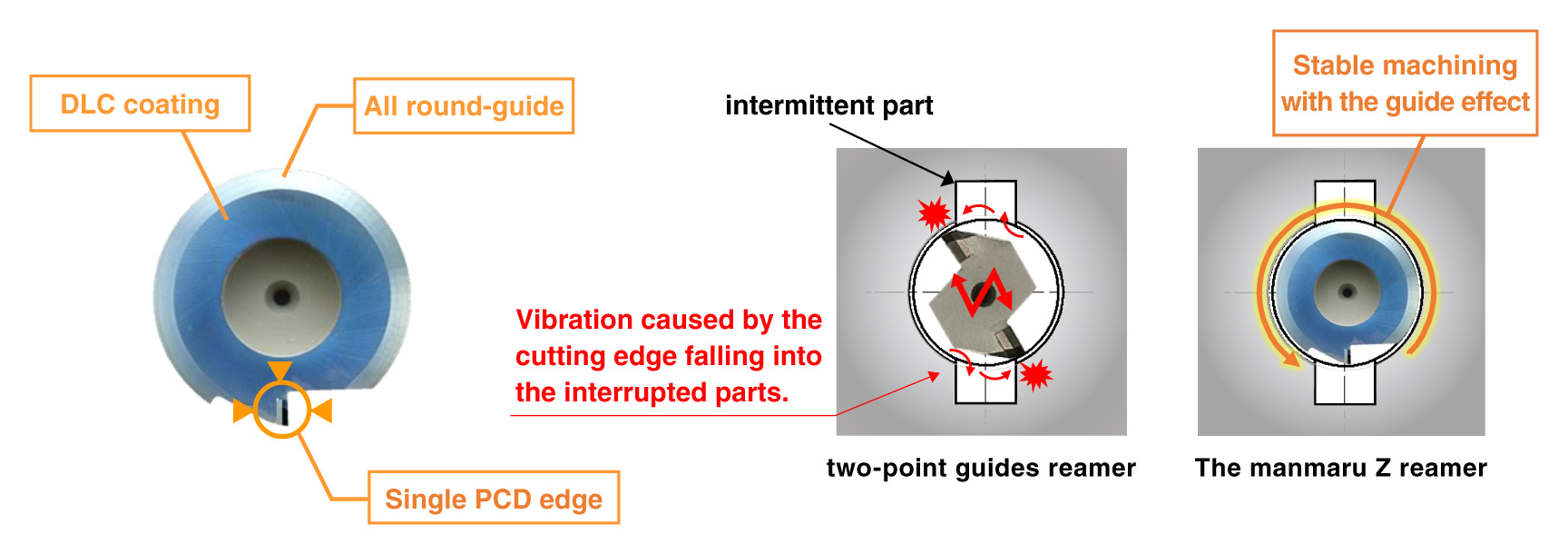

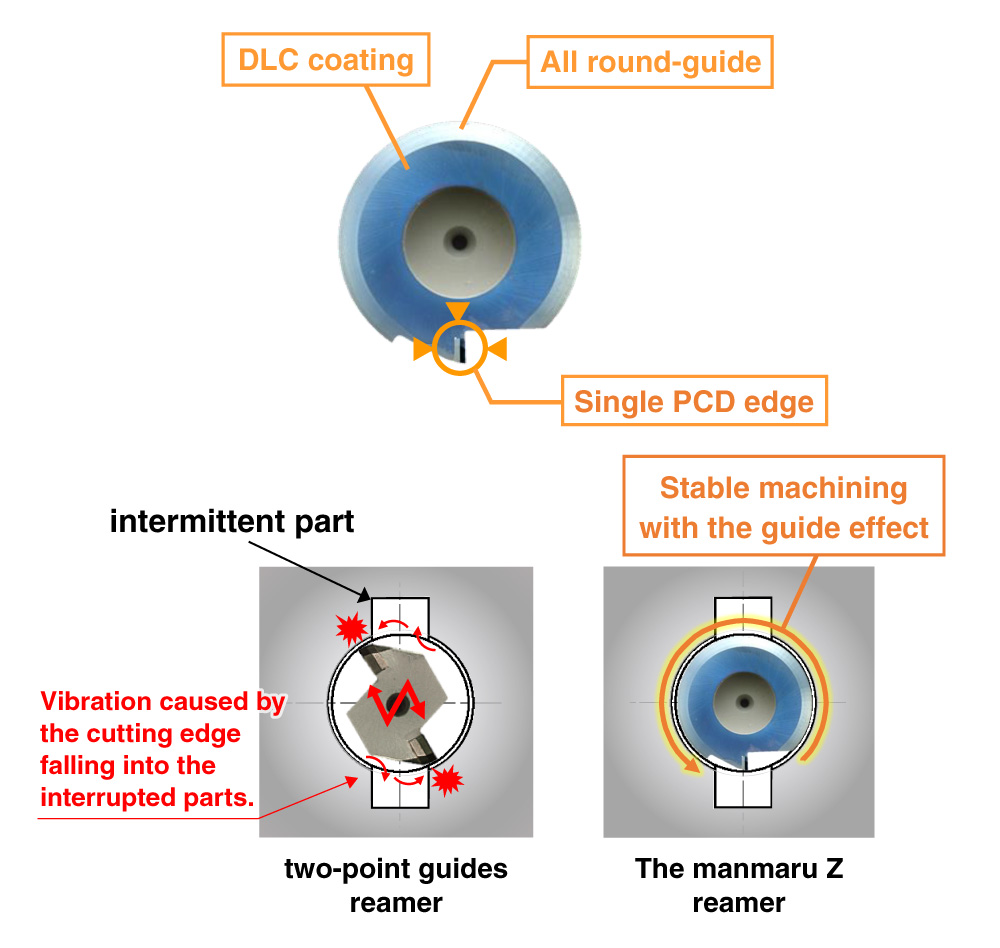

The True Circle (manmaru) reamer consists of an all-round guide + a single PCD edge.

The all-round guide provides excellent guiding performance even in intermittent cutting and enables stable machining.

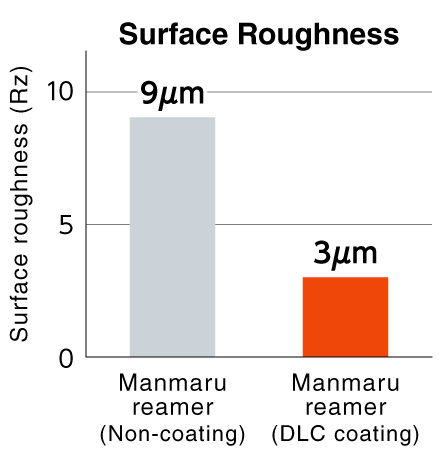

In addition, the single PCD edge + DLC coating improves resistance against welding and results in ‘high-precision machining’.

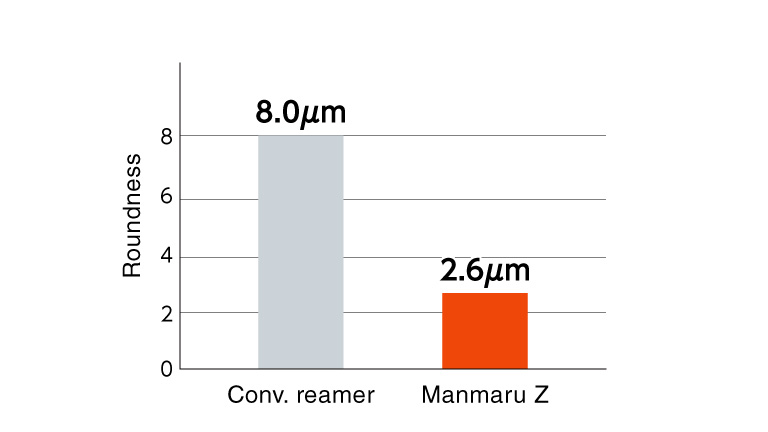

Excellent RoundnessGood !

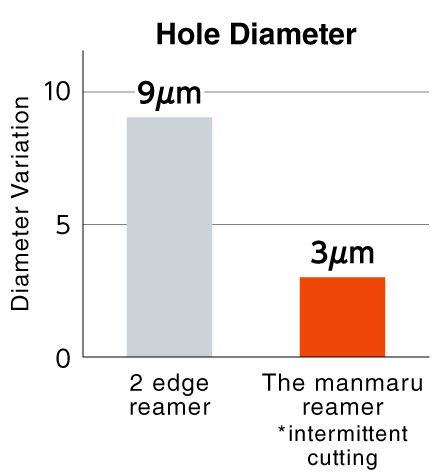

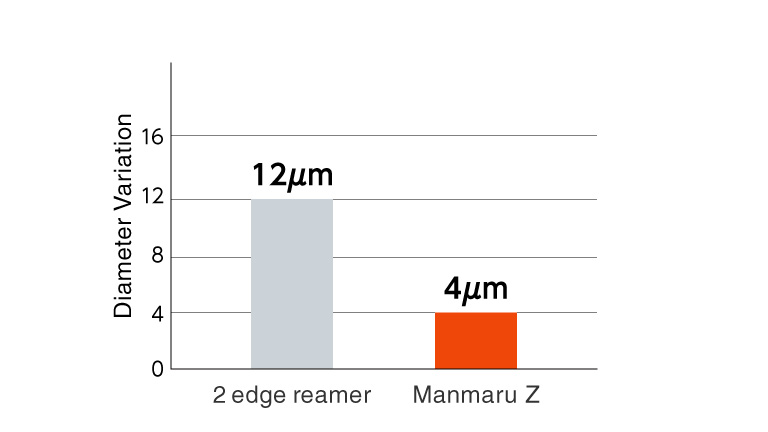

Stable Hole DiameterGood !

Improved Welding Resistance with DLC CoatingGood !

POINT!

High guiding properties provides high accuracy.Excellent !

Background / Point for Development

Background

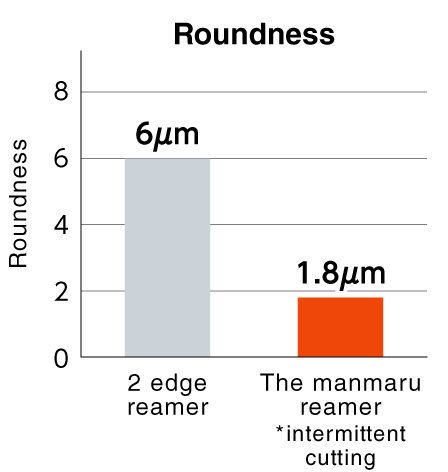

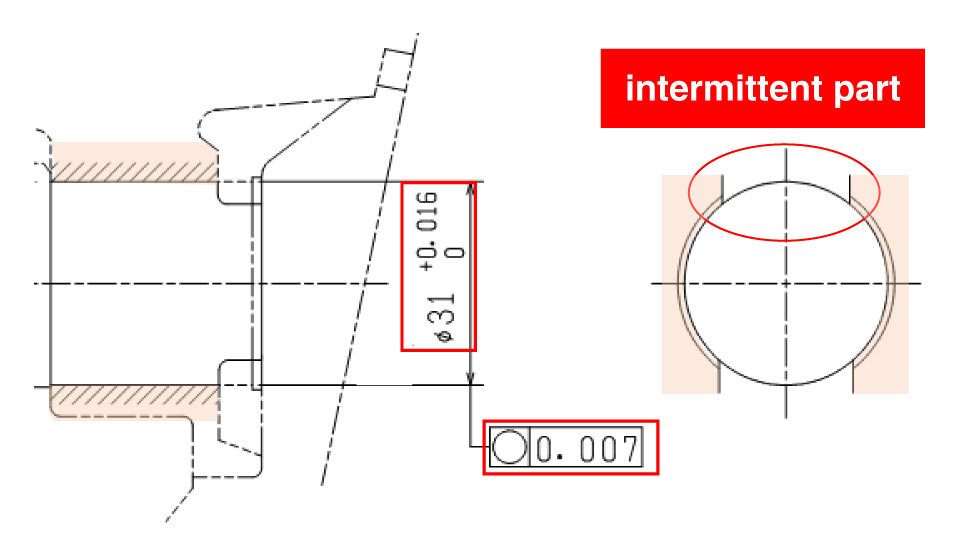

- When there are side holes or grooves in the machined hole, intermittent cutting occurs, and the hole diameter and roundness are not stable with conventional two-edge PCD reamers, making high-precision machining difficult.

Point for Development

- All-round guide + single PCD edge prevents the tool from making undesired behaviour during machining, which results in an excellent machining accuracy even in intermittent cutting.

- DLC coating prevents aluminium welding, which was a concern with all-round guides.

ExampleIntermittent Hole

| Tool | Manmaru Z reamer |

|---|---|

| Workpiece | Cylinder head (Lifter hole) |

| Material | AC2C-T6 |

| Tool Diameter | ø31mm |

| Cutting Conditions |

|

| Machining allowance |

ø0.3 |

| Required accuracy |  |

Lifter Hole

Roundness

Hole Diameter

Product Specification

Tool Specification

| Process covered |

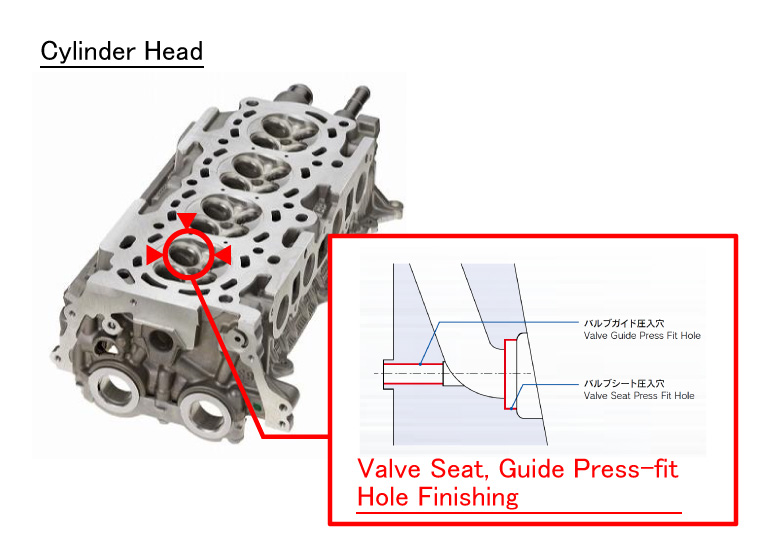

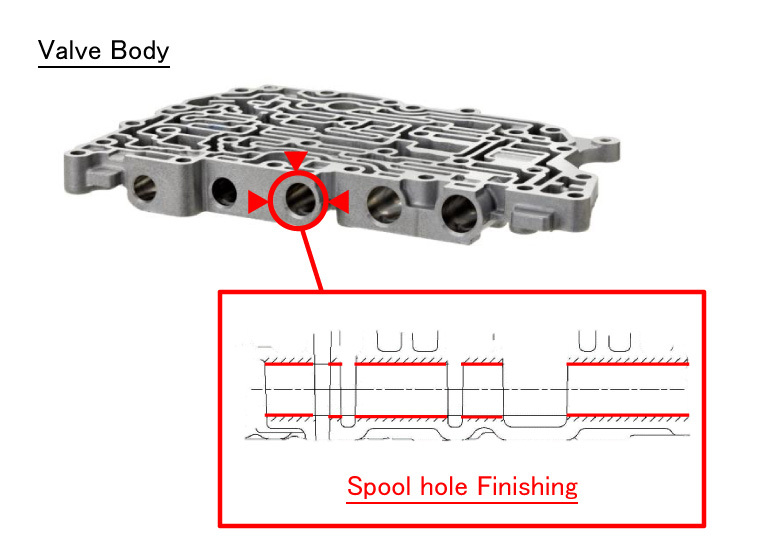

Valve seat, guide press-fit holes, spool holes, lifter holes and aluminum high-precision holes |

|---|---|

| Diameter | ø5 - |

| Standard conditions |

|

| Performance | IT7 |

Applicable work example