Holder with Chip Splash Prevention

Ultra-lightweight cover

for improved productivity.

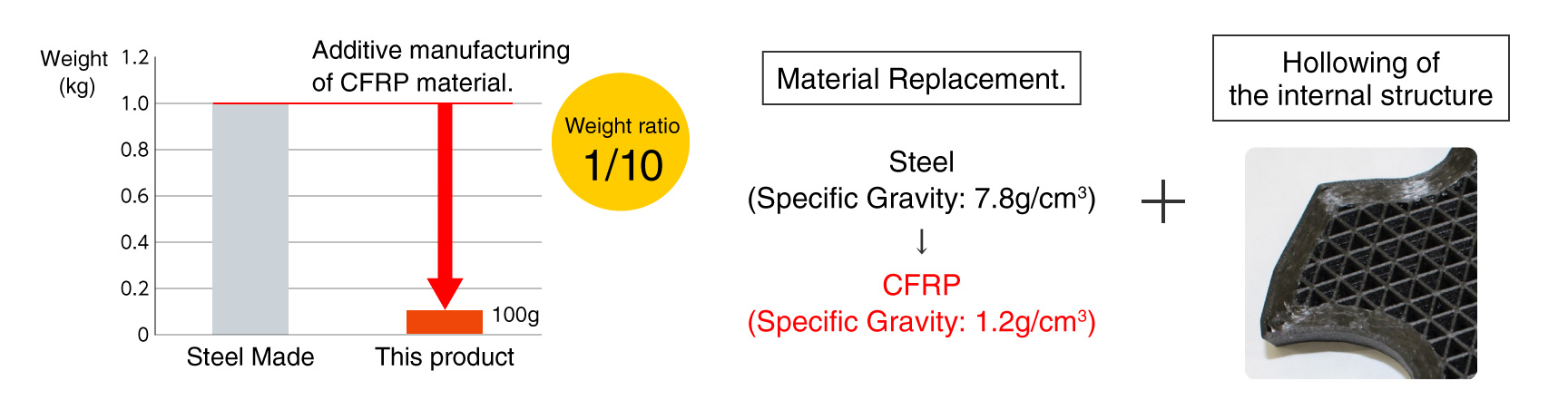

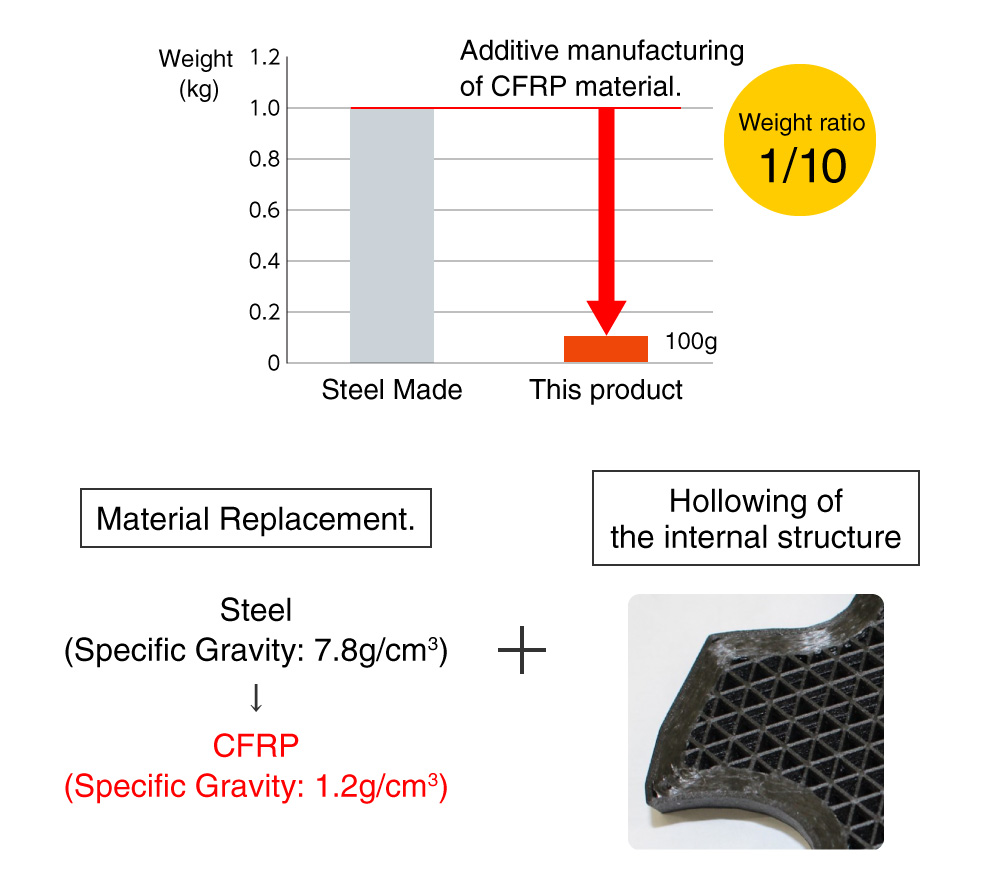

- “Lightweight material” + “molding technology” creates an ultra-lightweight cover.

Holder without chip problems.

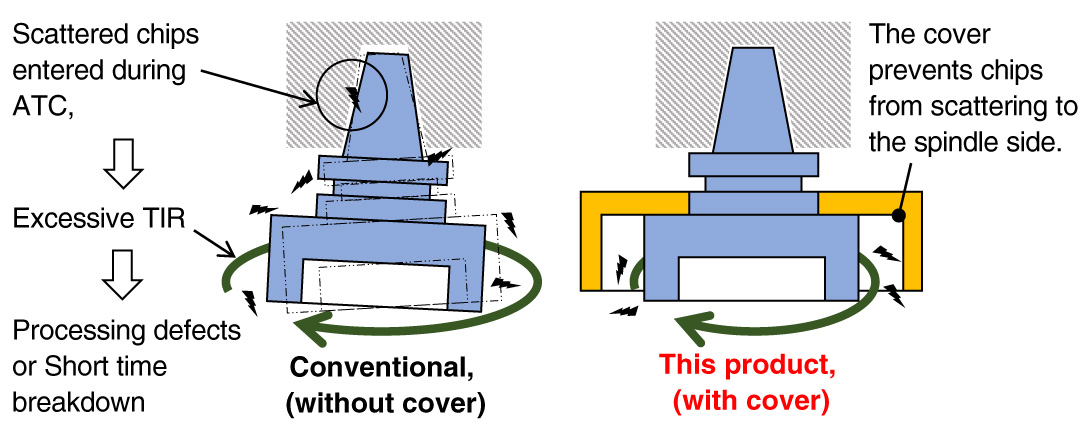

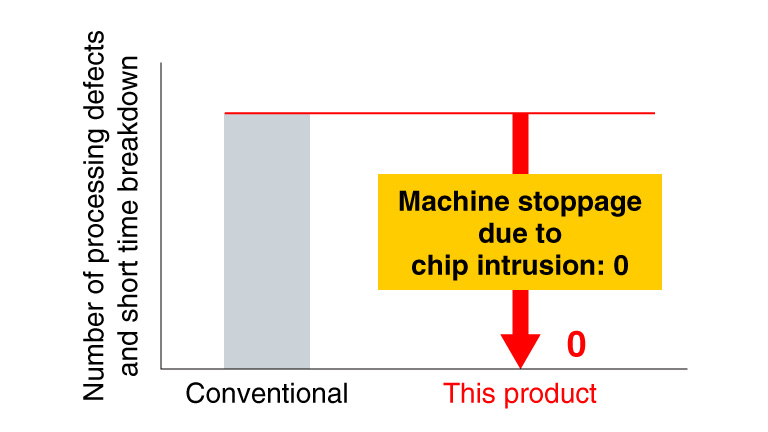

- Reduces machining defects and machine stops in the production line caused by chip scattering.

- Attachable to the currently used holder.

“Amazing Ideas / Facts!”

A holder with a cover that prevents chips from scattering around, thus results in better productivity.

The cover is made of CFRP laminated plastic:

- High strength-to-weight ratio, heat resistance, and cutting oil resistance.

- Ultra-lightweight, satisfying the weight limit of the spindle.

POINT!

The cover is made of CFRP, making it extremely lightweight.Excellent !

POINT!

Ultra-lightweight cover prevents chips from scattering toward the spindle side.Excellent !

Improving Production EfficiencyGood !

Background / Point for Development

Background

- Chips around the spindle during machining can sometimes enter the interface during ATC, causing deterioration in machining accuracy and short time breakdown in the production.

- A metal cover to prevent chips from scattering was too heavy and did not meet the weight limit on the spindle side.

Point for Development

- A holder with an ultra-lightweight cover can prevent chips from scattering onto the spindle side.

- The CFRP additively manufactured product used for the cover has a high strength-to-weight ratio, and the nylon base resin has both heat resistance and cutting fluid resistance, so it can be used inside processing machines.

- It is extremely lightweight and meets the weight limit of the spindle, allowing the cover to be installed while preventing problems caused by scattering chips.

Product Specification

- *Can be specially designed and manufactured according to the purpose and application.

[For details, see “Service”: “3D printing service”]

| Size (mm) | See diagram*1 |

|---|---|

| Weight (g) | 60*1 (60 - 160) |

| Cover material | CFRP |

| Heat resistance | 145°C |

| Cutting fluid resistance | Yes |

- *1:Items in parentheses indicate actual performance.