3D printing services

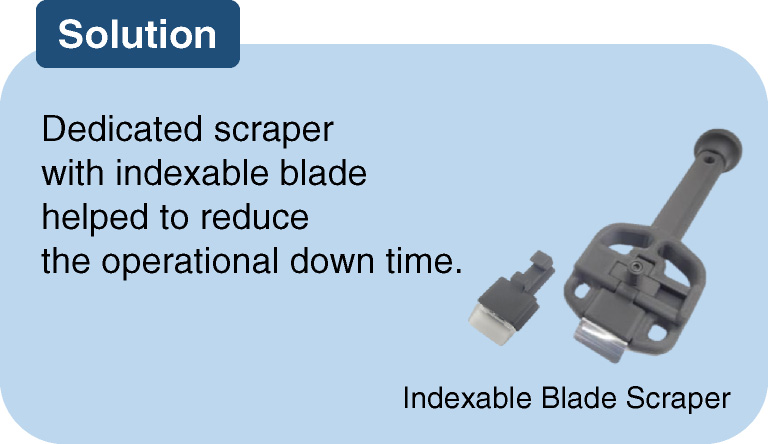

Solving ‘challenges’

with AM (Additive Manufacturing)

technology

- As well as from our expertise in the special tool

manufacturing, we aim to improve your production

with our 3D printing technology

- We offer solutions from issues and ideas

- No.1 in the industry,

covering the area of outsourcing - The products will be used in

a wide applicable areas with “high rigidity”,

“heat resistance”,

“coolant resistance”

“Amazing Ideas / Facts!”

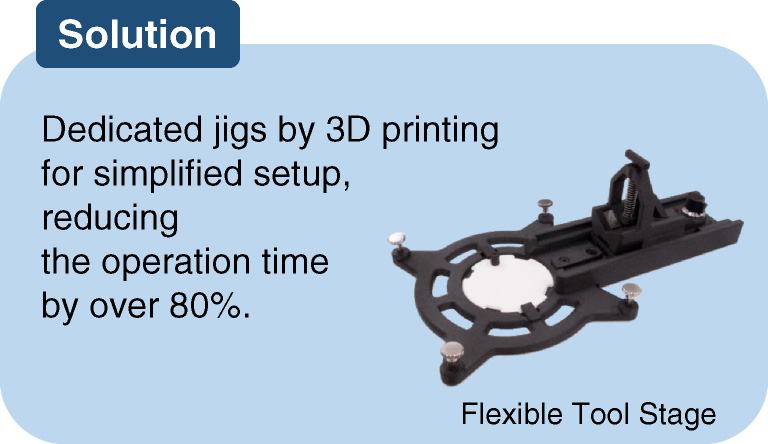

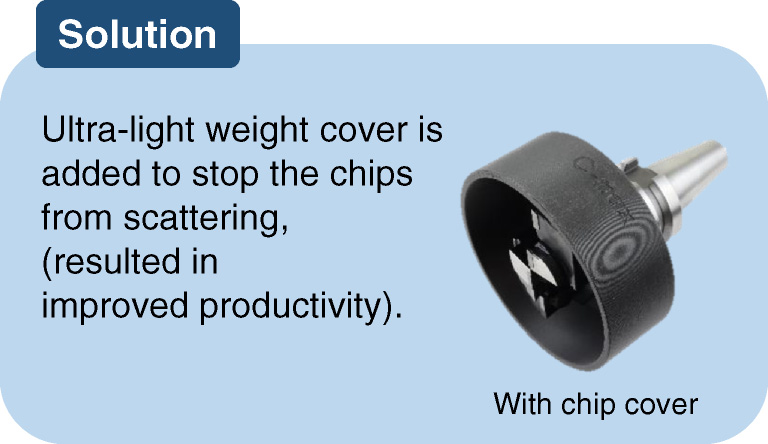

With our 3D printing technology, we aim to solve the challenges that customers are experiencing.

The service includes the optimal concept making until the realization of final products, all deriving from FUJISEIKO's product development expertise.

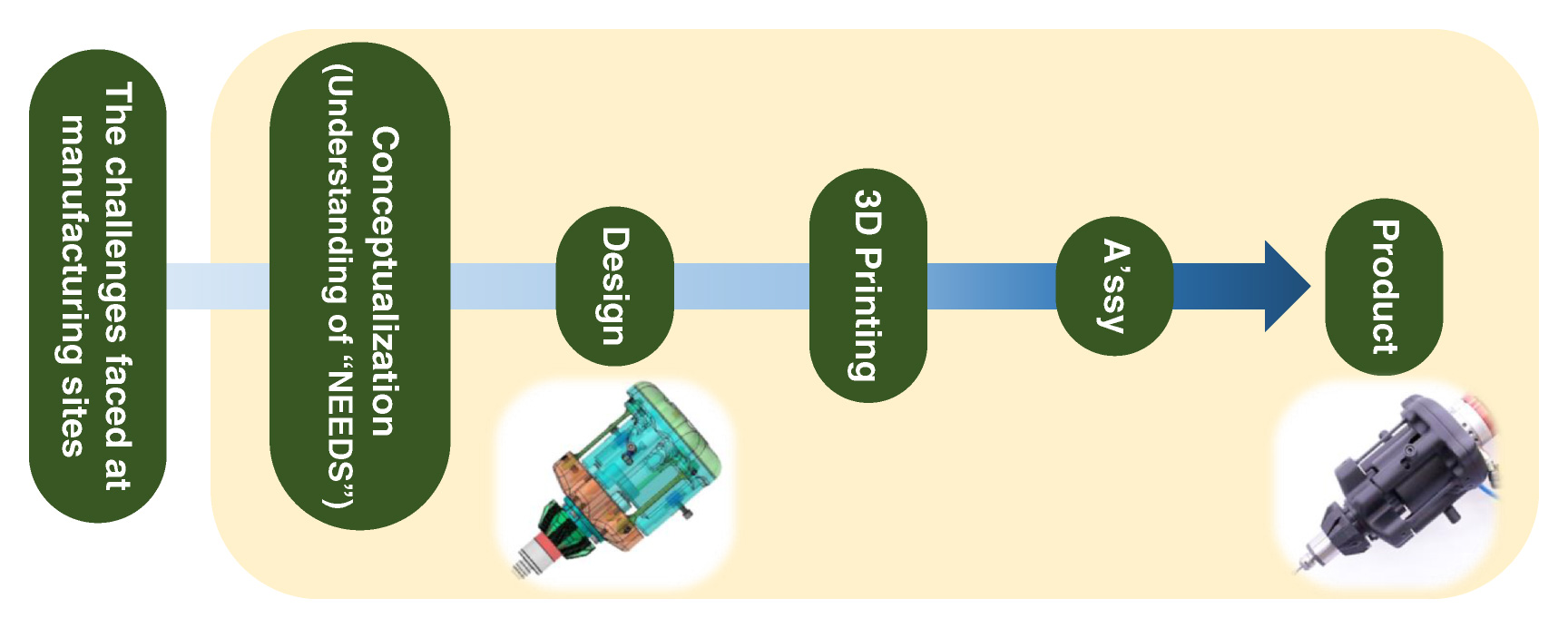

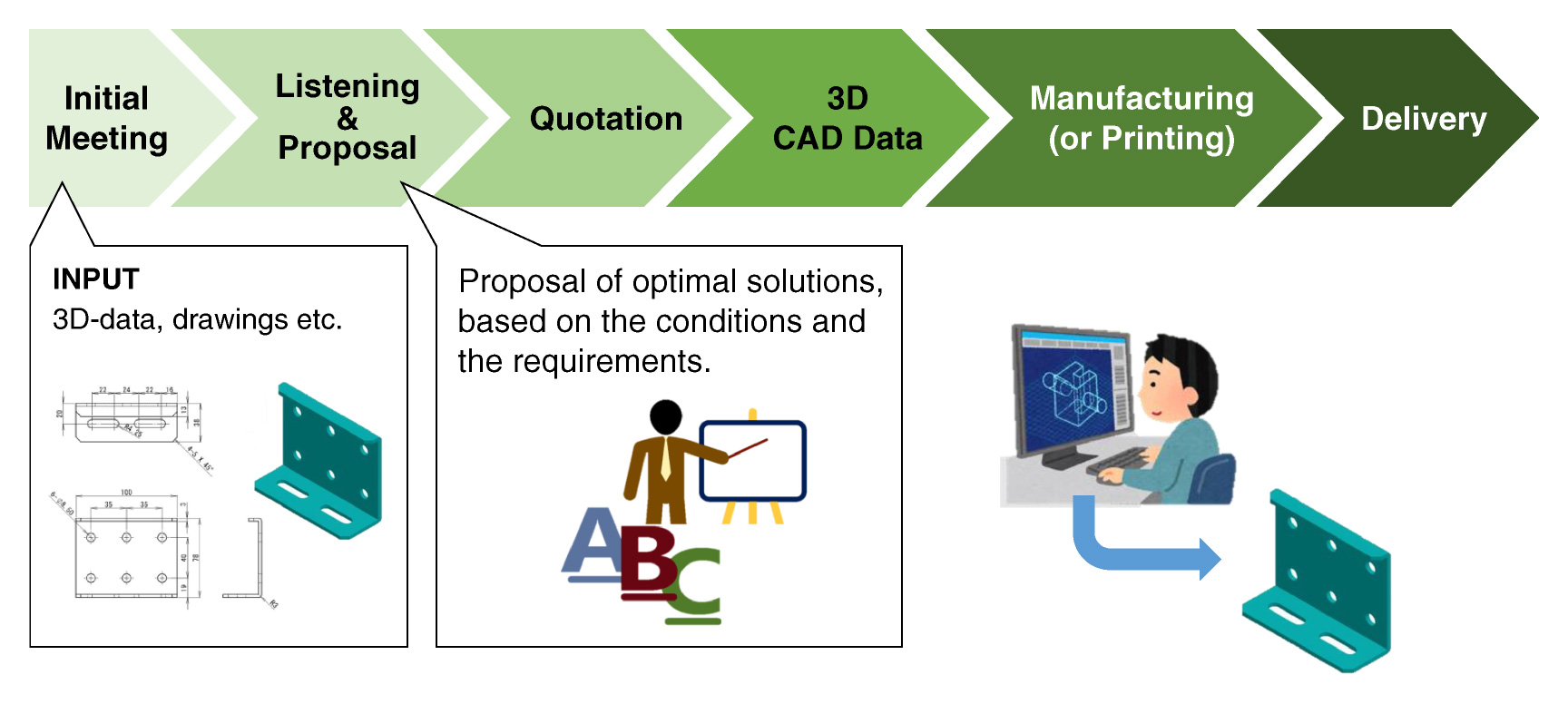

The Process Flow until Delivery

Total service from conceptualization to the finished product

OK with any requests or proposed methods!!

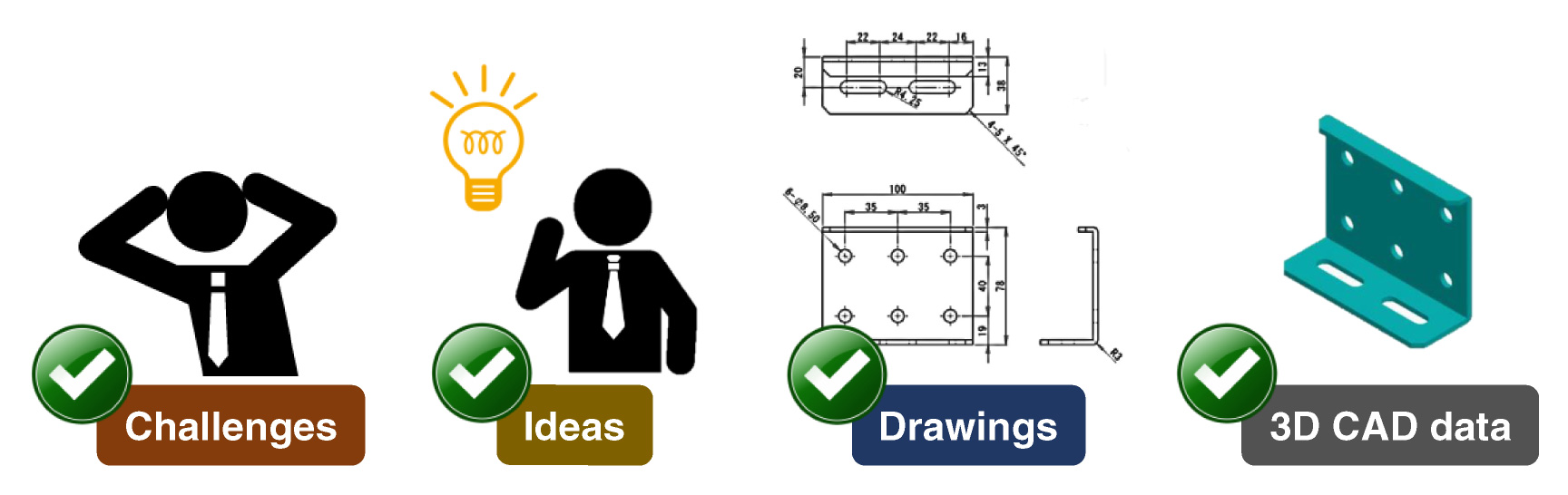

Services Flow

Services Flow (in case where 3D data, drawings are available)

- *This is the workflow for cases where 3D data or drawings of the desired jig are available.

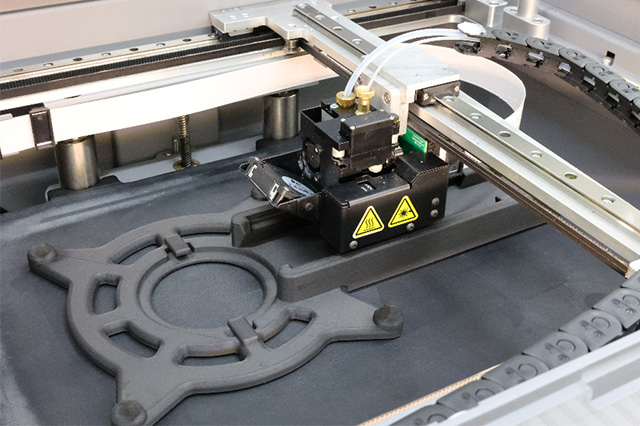

3D printer at FUJISEIKO

“X7” (Markforged)

The molded parts possess high strength and impact resistance, properties suitable for jigs, functional prototypes, and final products.

When reinforced with long carbon fibers, they exhibit strength comparable to aluminum.

Characteristics

| Printing Technology |

FFF (Fused Filament Fabrication) |

|---|---|

| Applicable size (mm) |

330(W) × 270(D) × 200(H) |

| Layer Height (µm) |

50, 100, 125, 200, 250 |

Materials

| Base resin | CFRP (Nylon with carbon short fiber) |

|---|---|

| Additional fiber | Long Carbon fiber |