Scraper with Indexable Blade

Contributing to environmental improvement

by combining resin and metal.

- An optimal cutting edge structure is achieved using integrated molding technology.

- Scraper designed for removal performance and workpiece protection.

- High removal performance reduces solvent usage.

- Optimized cutting edge specifications prevent damage to the workpiece.

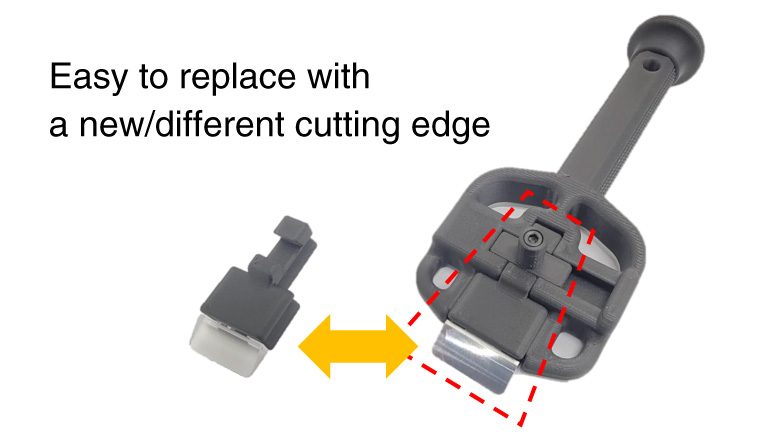

- Replaceable blade reduces running costs.

“Amazing Ideas / Facts!”

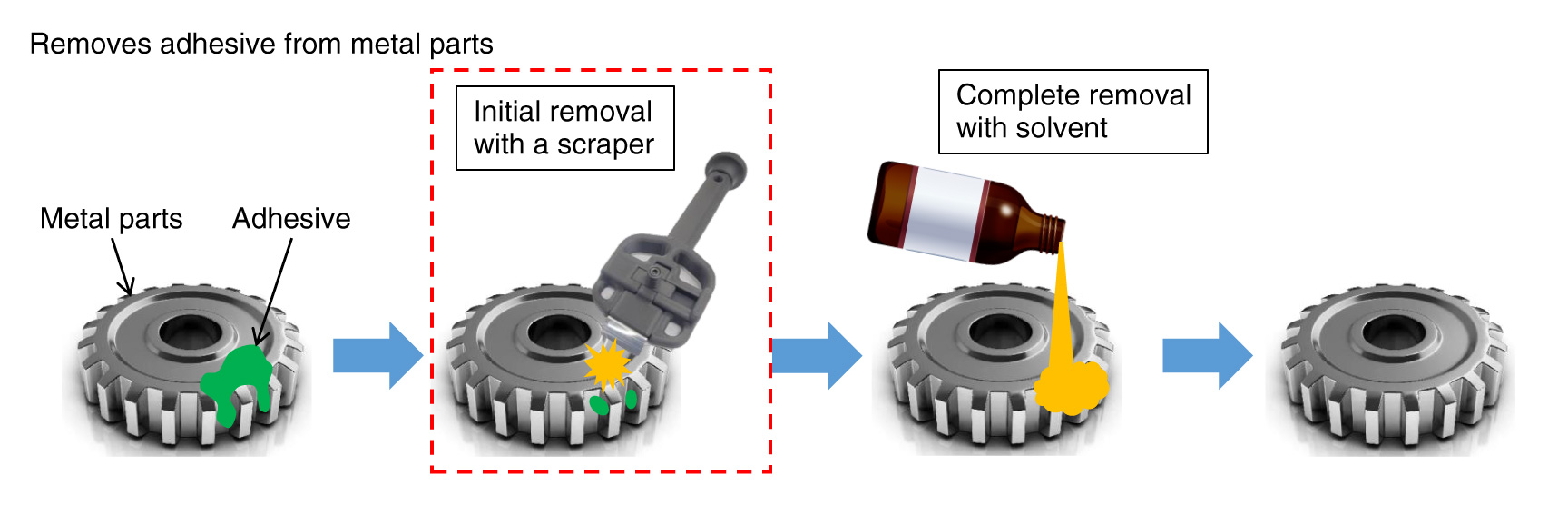

“Scraper with indexable blade” is to remove adhesive that remains on metal parts.

The cutting edge is made of A7075 series aluminum alloy and the optimum shape can be selected according to the application, achieving high removal performance without damaging the workpiece.

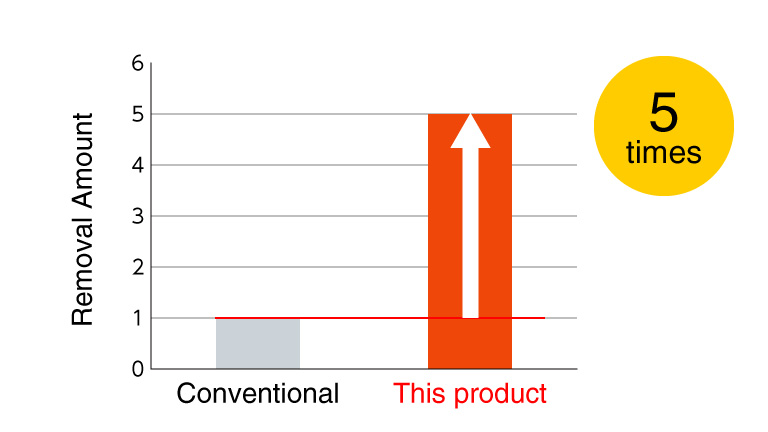

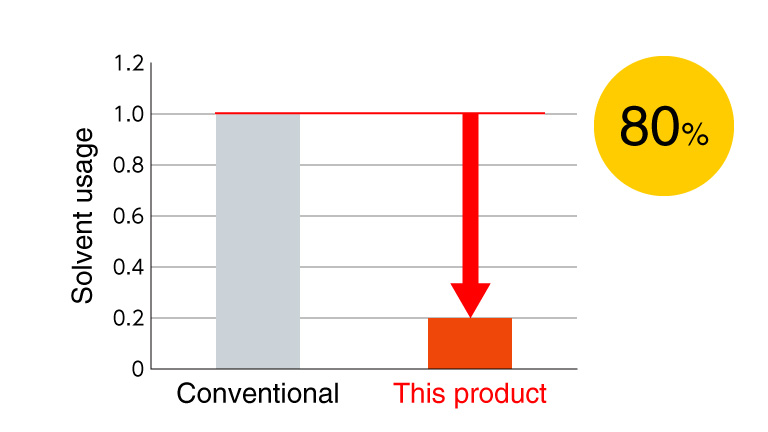

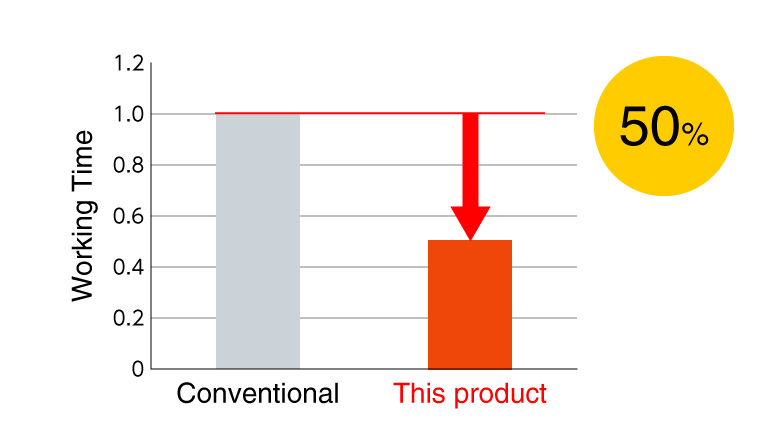

Compared to conventional removal work, it significantly increases the amount of removal and reduces the amount of solvent use thereafter, contributing to more efficient & shorter working time.

The overall running cost can be reduced by exchanging edges when worn out or for the use of different purposes.

How to use “Scraper with Indexable Blade”

Improvement of Removal PerformanceGood !

Reduction of solvent usageGood !

Working Time ReductionGood !

Running Costs ReductionGood !

Background / Point for Development

Background

- Adhesive is often used to hold products during wire EDM processes. Then solvents are used to completely remove the adhesive. But due to the high environmental and safety risks associated with the chemicals, there was a need to reduce the amount of solvent used and shorten the work time.

- Conventional scrapers in the market are used before the solvent use but they tend to scratch workpieces and to wear out quickly, requiring more frequent replacement to new scrapers.

Point for Development

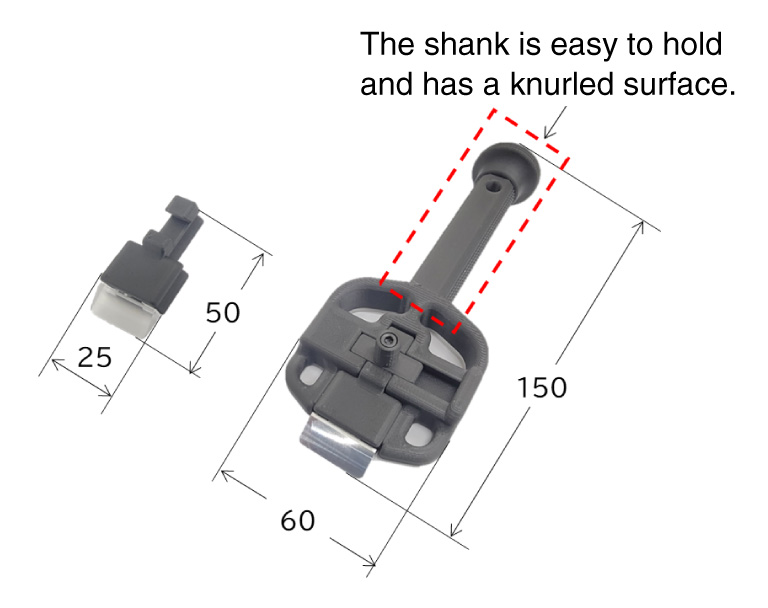

- The “Scraper with Indexable Blade” uses our unique molding technology to achieve an optimal blade structure and a shank shape that is easy to hold.

- The cutting edge is made of A7075 series aluminum alloy to maintain optimal removal performance and to protect workpieces.

- Results in removal of more adhesive before the solvent process, helping to reduce the amount of solvent used and the replacement costs when the blade wears out.

- It shortens the total working time.

Product Specification

- *Can be specially designed and manufactured according to the purpose and application.

[For details, see “Service”: “3D printing service”]

| Size (mm) | See diagram |

|---|---|

| Weight (g) | 45 |

| Cutting Edge Material | A7075 series aluminum alloy |

| Body Material | CFRP |