Automatic Tool Change

ATC stub holder

An essential item

for robotic machining!

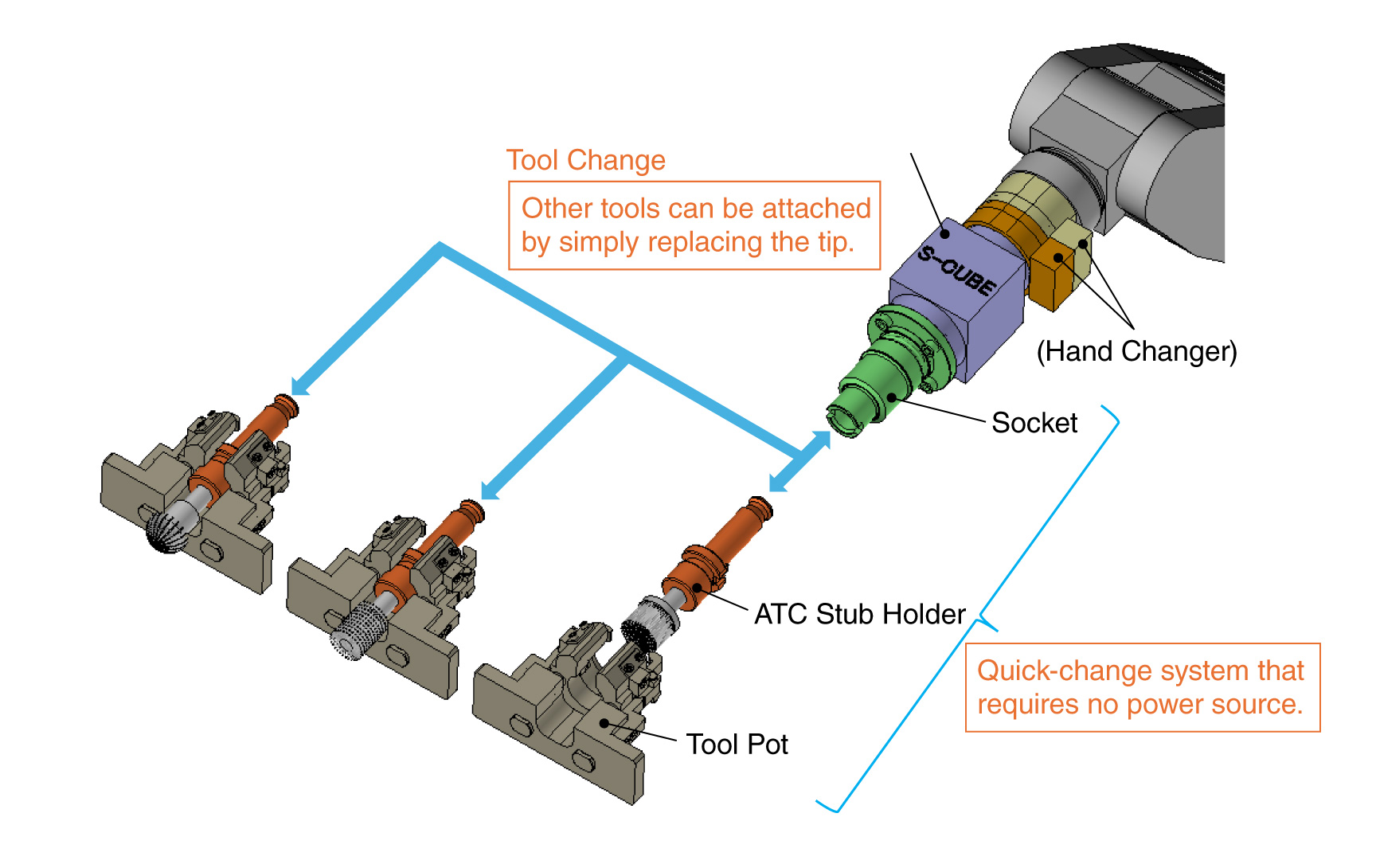

- Tools can be attached and detached using only straight movement.

Tool change system for robotic machining.

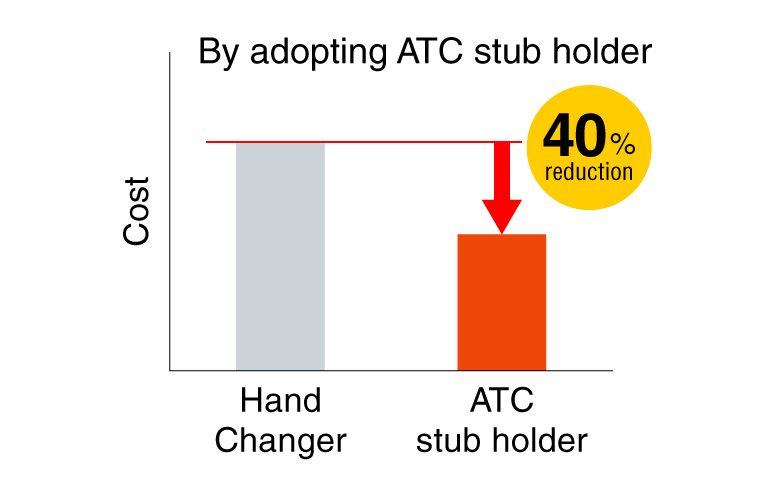

- Reduce investment by not requiring multiple hand chargers.

- Easy tool change with no power source required.

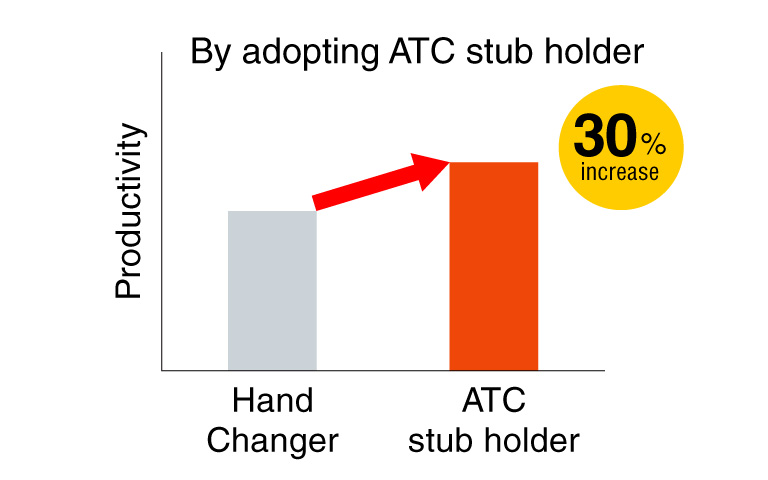

- 30% increase in productivity due to reduced tool change time.

“Amazing Ideas / Facts!”

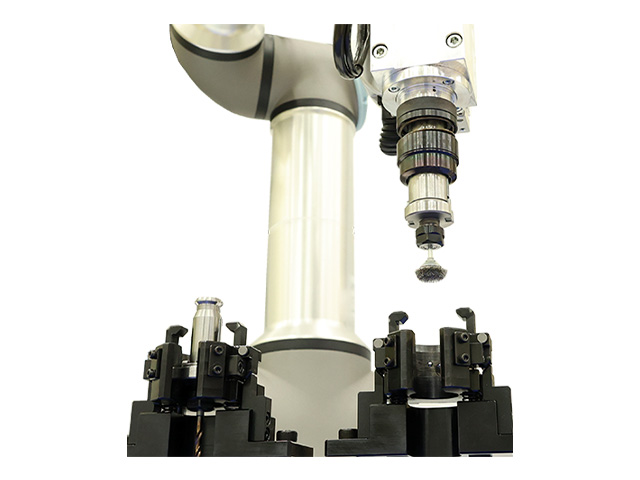

The ATC stub holder is a quick change system for robotic machining that allows the tool attached to the tip of the hand changer to be replaced with other tools.

By adopting a mechanical mechanism for the replacement method, power sources such as electricity or air are not required, and it can be installed directly on existing robots.

It also allows for quick tool changes, contributing to improved productivity, reduced investment, and support for a wide variety of products.

Reduction of capital investmentGood !

Productivity improvementGood !

POINT!

Easy replacement of the tip of the robot hand changer.Excellent !

Spindle unit

Details: See ultra-compact spindle

S-CUBE.

POINT!

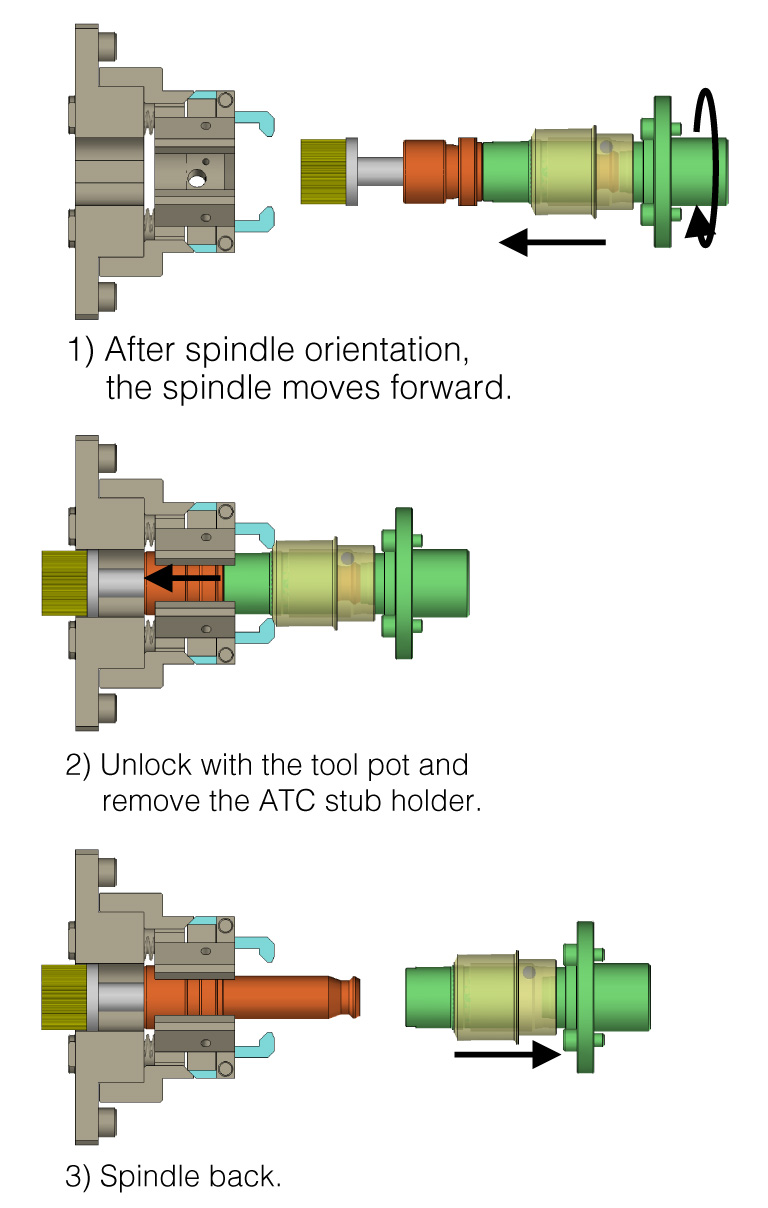

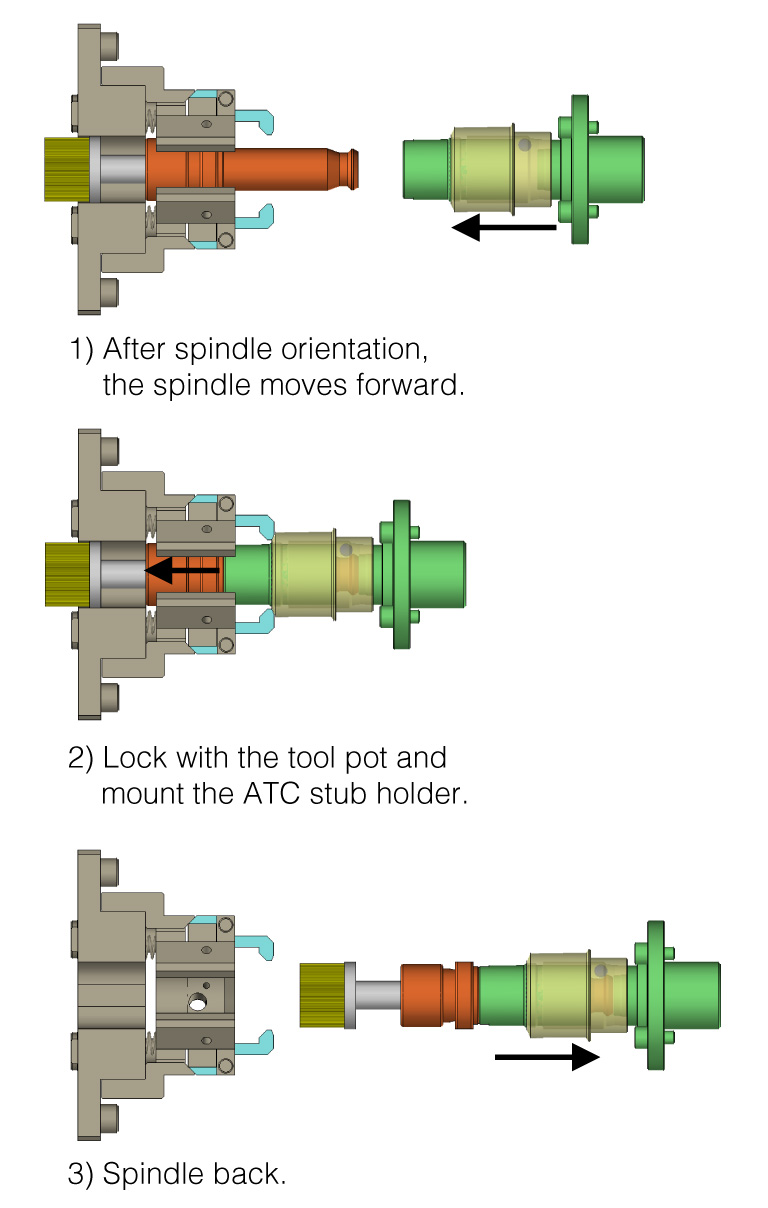

Stub holder exchange procedure.Excellent !

Removing the stub holder

Stub holder mounting

Background / Point for Development

Background

- Factory production lines are becoming more efficient by replacing human work with robots.

In order for the robot to perform a variety of tasks effectively, frequent tool changing operations are required.

Speedy processing and automation of this process are essential for improving productivity.

Point for Development

- The ATC stub holder has developed a quick change system with a mechanical mechanism that does not require a power source, allowing for quick tool changes using only the tip of the hand changer.

- In addition, since only the tip is replaced, there is no need to prepare multiple tool changers, contributing to improved productivity at low cost.

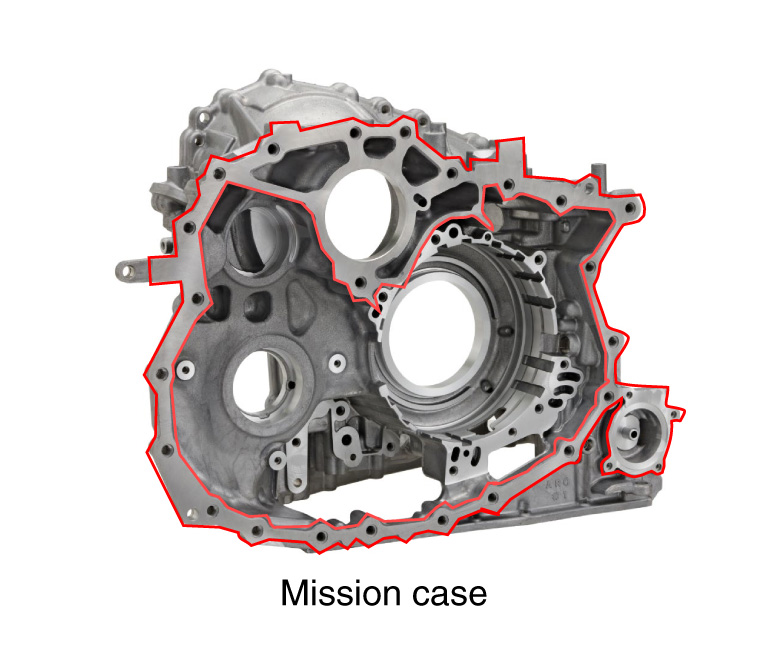

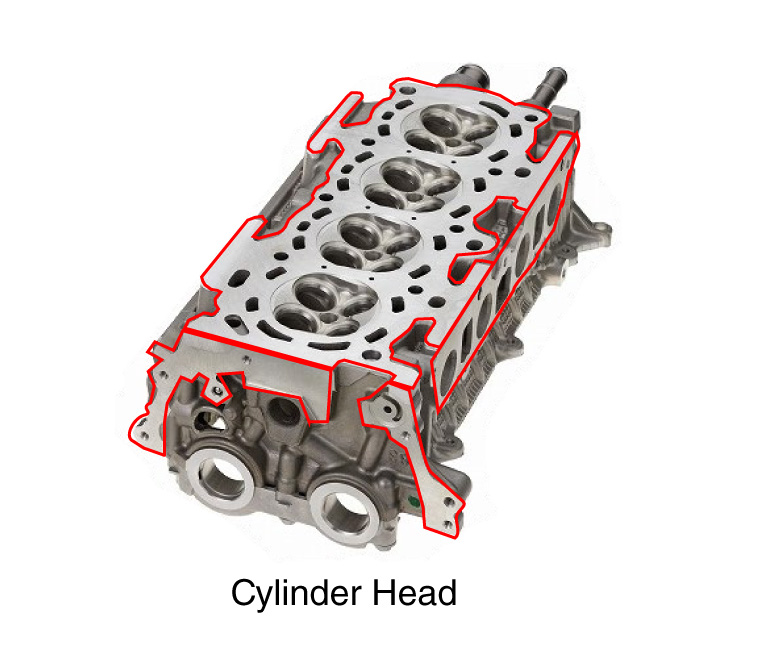

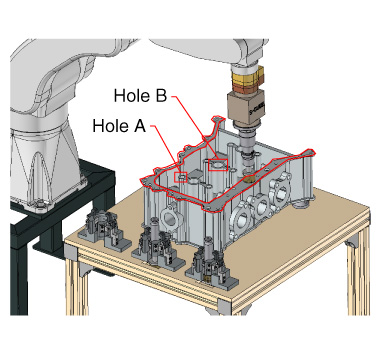

Example

| Workpiece | Cyl-Head |

|---|---|

| Material | Aluminum |

| Process | Brushing for mating surfaces |

| Cutting condition (Mounting surface) |

|

| Cutting condition (Hole A) |

|

| Cutting condition (Hole B) |

|

Product Specification

Tool specification

| Target process | Brushing for mating surfaces, etc… |

|---|---|

| Target equipment | Collaborative robots, industrial robots. |

| ATC power source | Not. Required. |

Applicable workpiece examples