Test-cut service

Total support for solving

machining related problems

- Quantitative approach

from the initial challenge to the solution - Proposals after the machining condition analysis

- Total support

(from Pre-meeting to the final report) - Quantitative data & report

from various measuring sources - Countermeasure/Improving proposal

based on the test result

“Amazing Ideas / Facts!”

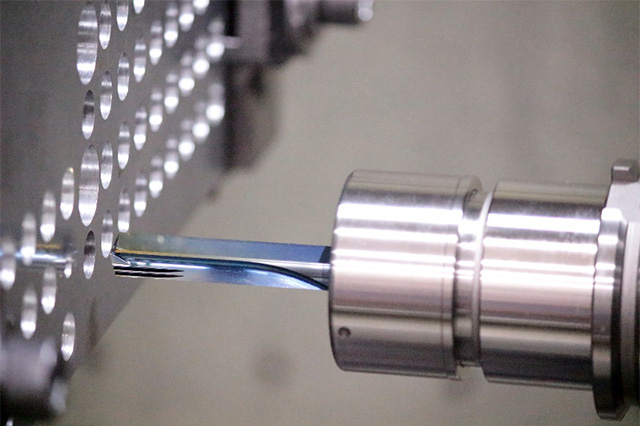

We provide almost conditions and environment necessary for your test and the result right in front of your eyes.

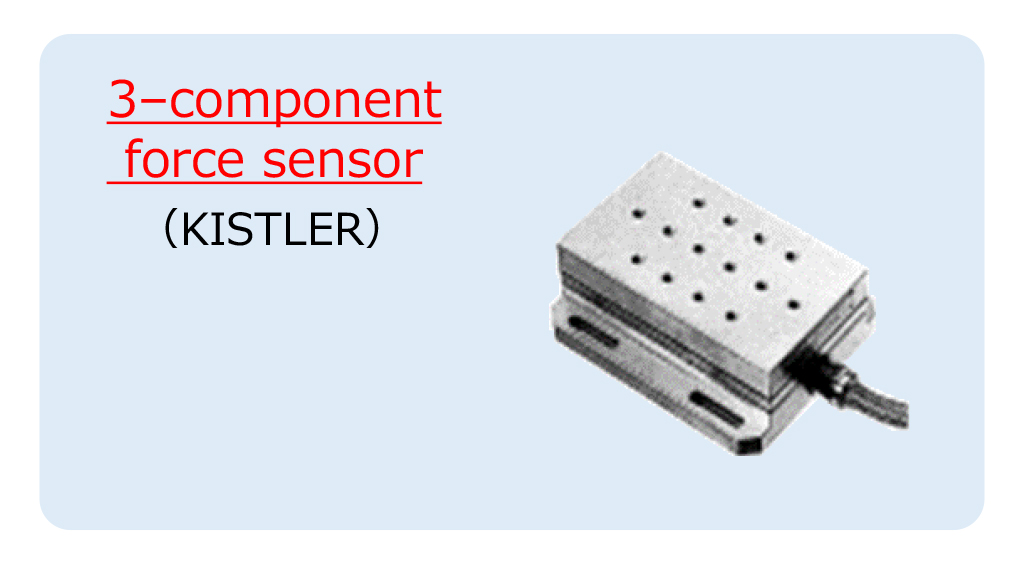

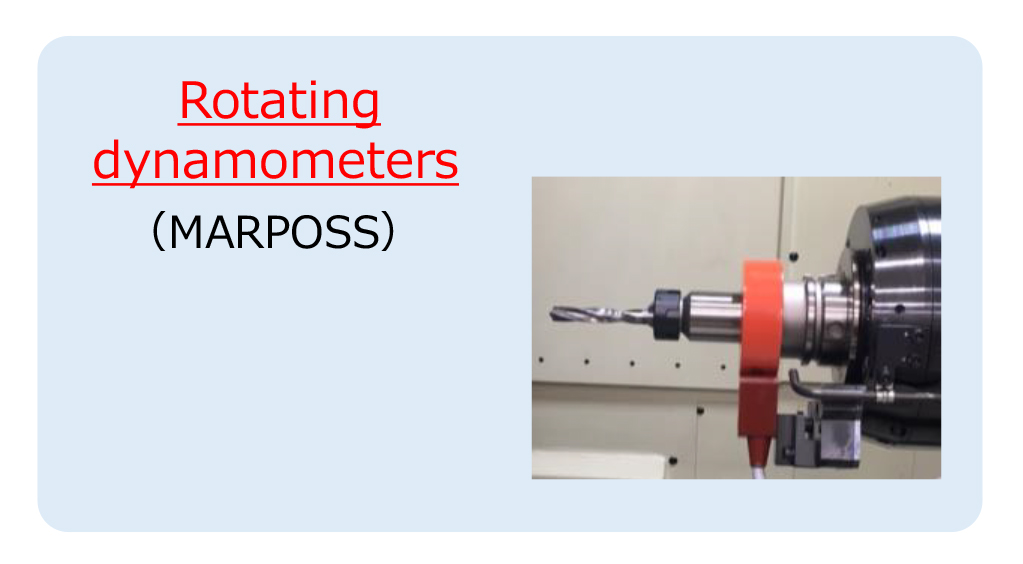

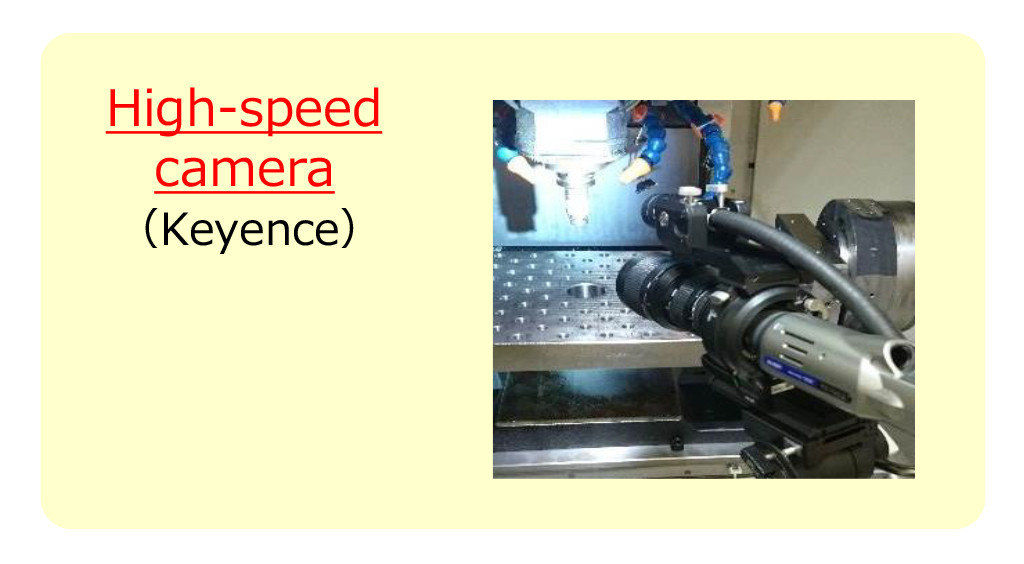

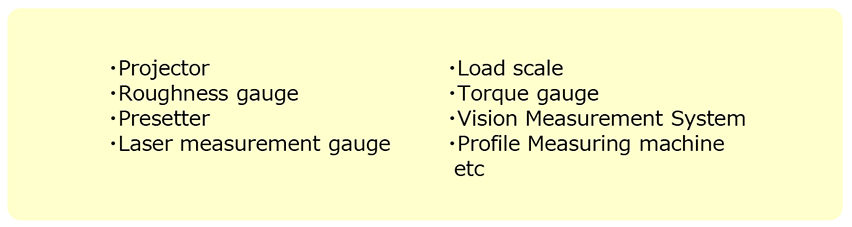

Subsequent, detailed analysis can easily be made with our “refined” (or “wide range of”) testing & measuring equipment.

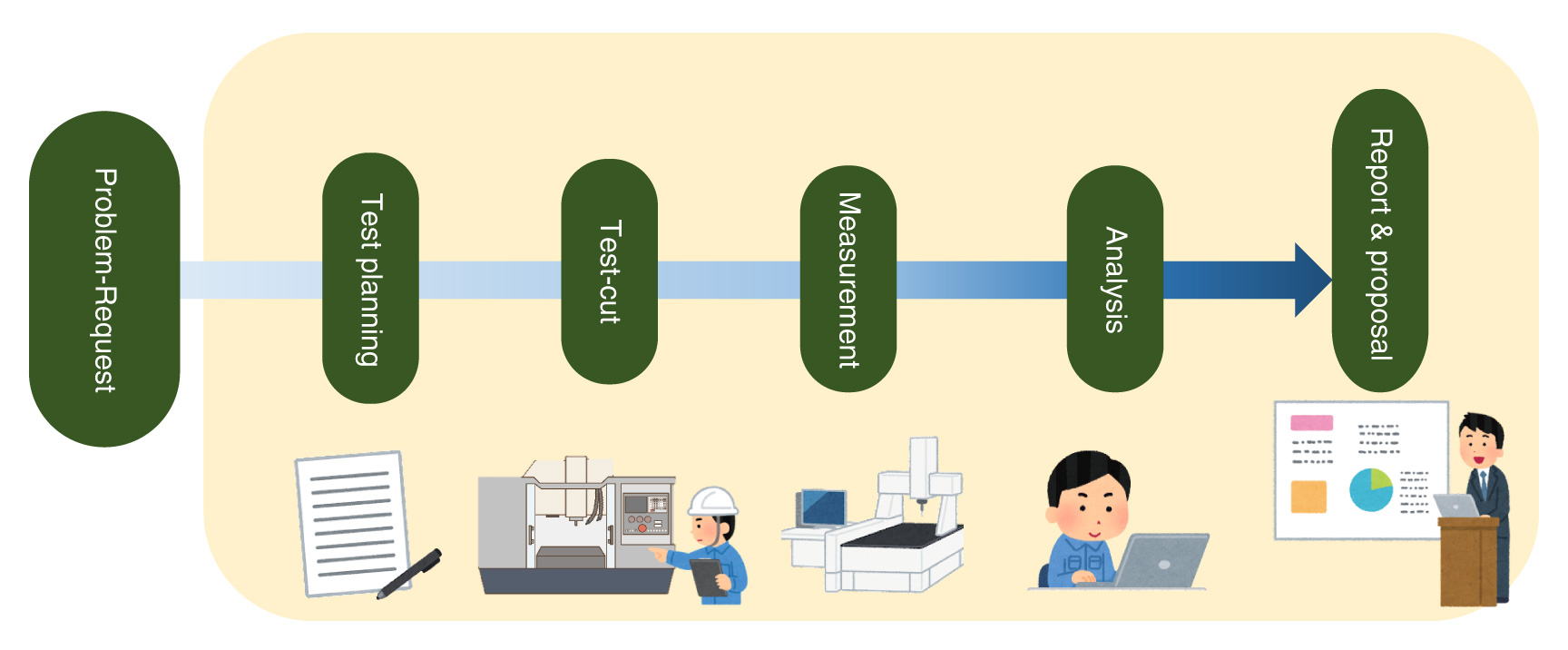

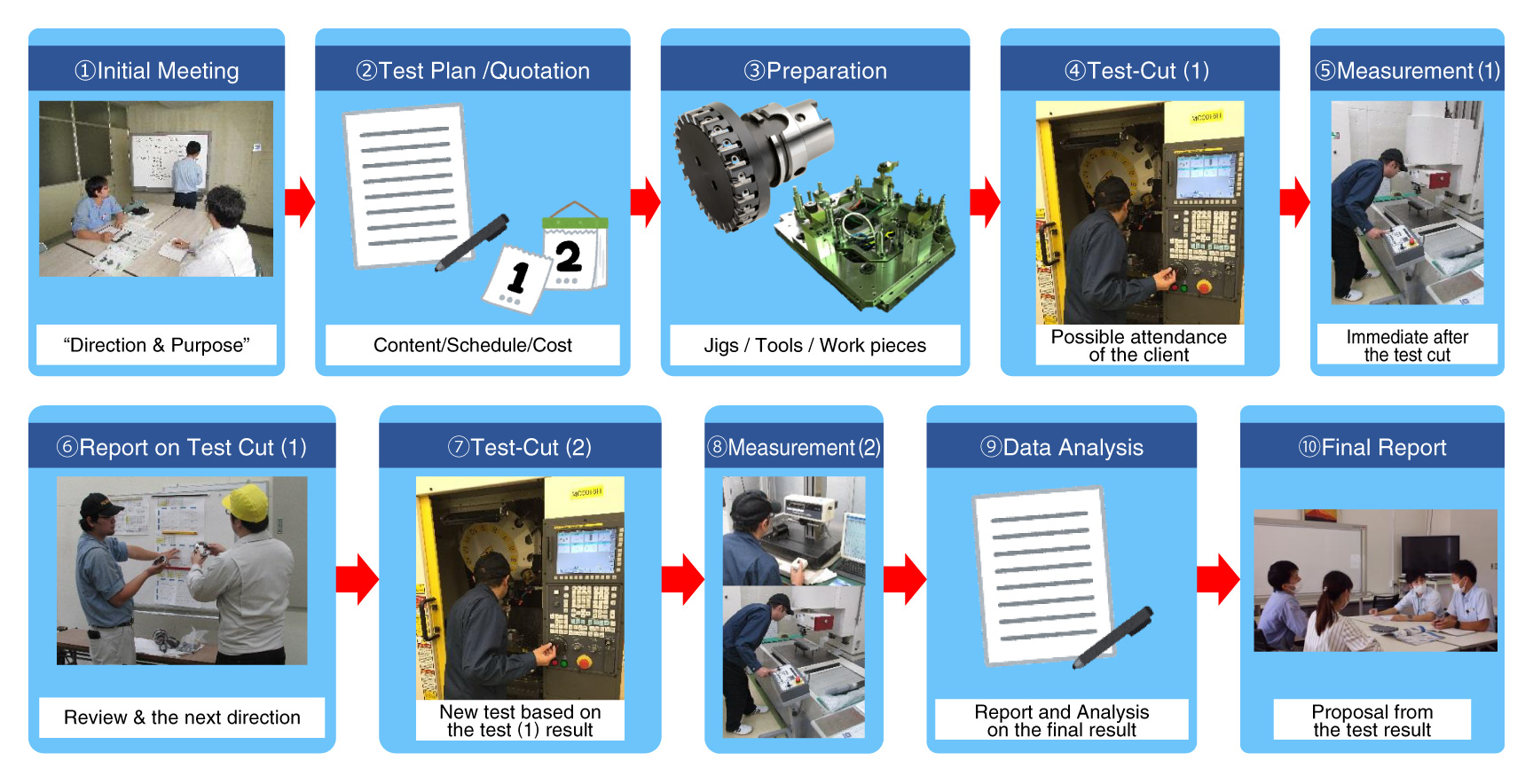

The Service flow

Comprehensive service from test planning, validating, reporting and to the technical proposal

Other aspects of the service

Examples of Test-Cut Service

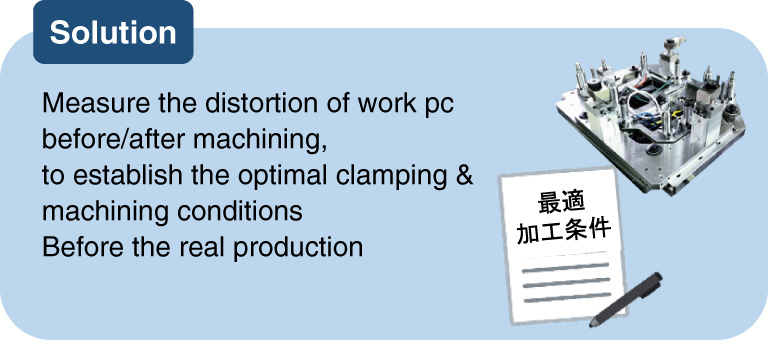

| Case 1 |

Deciding acceptable/good product condition …

|

|---|---|

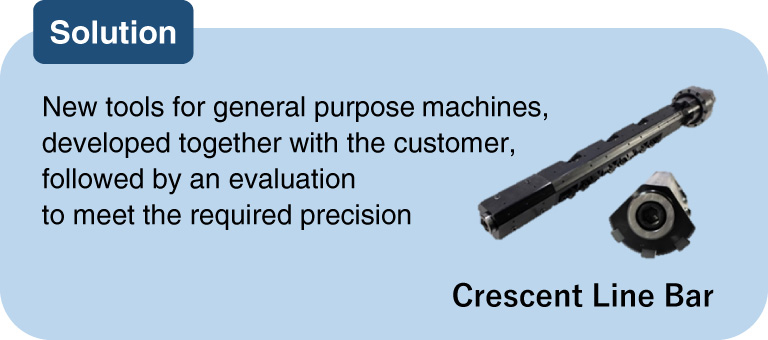

| Case 2 |

Collaborative development (Collaboration) with customers … |

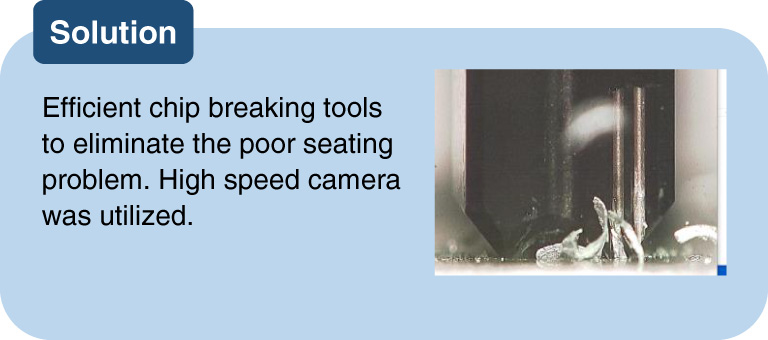

| Case 3 |

Problems in real productions … Monitoring with high speed camera

|

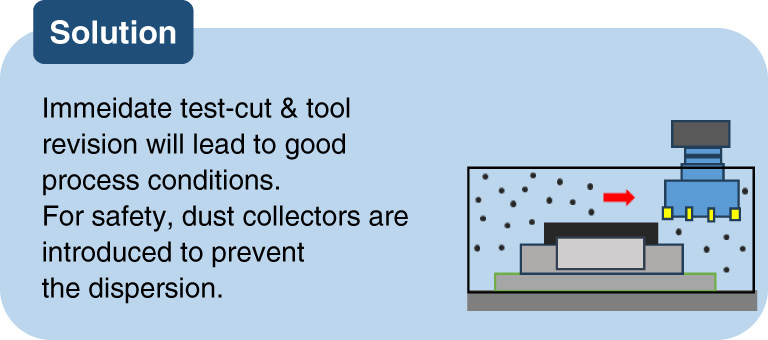

| Case 4 |

The optimal machining conditions for “new” or “hard-to machine” materials.

|

| Case 5 |

Total support for challenges observed at the production site.

|

Services Flow

Example: Service Flow

Available facilities at FUJISEIKO

Horizontal Machining Center: “a61nx” (Makino)

| Spindle Taper | HSK63 |

|---|---|

| Spindle RPM | 20,000min-1 |

| Rapid traverse | 60,000mm/min |

| Cutting traverse | 50,000mm/min |

| Range of motion | X: 730mm Y: 730mm Z: 800mm B: 360° |

| Max. Tool Weight | 12kg |

| Additional function | Cutting Power Meter |

Vertical Machining Center: “α-T14iFa” (Fanuc)

| Spindle Taper | BT30 |

|---|---|

| Spindle RPM | 10,000min-1 |

| Rapid traverse | 48,000mm/min |

| Cutting traverse | 30,000mm/min |

| Range of motion | X: 500mm Y: 400mm Z: 330mm |

| Max. Tool Weight | 3kg |

| Additional function | Servo Viewer Spindle Power Meter Vibration Monitoring |